Cross-linked polyether reverse demulsifier and preparation method thereof

A reversed-phase demulsifier and cross-linking polymerization technology, applied in separation methods, chemical dehydration/demulsification, mining wastewater treatment, etc., can solve the problems of sludge clogging water treatment facilities, slow dispersion rate, and insignificant effect. To achieve the effect of good water quality and fast water purification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

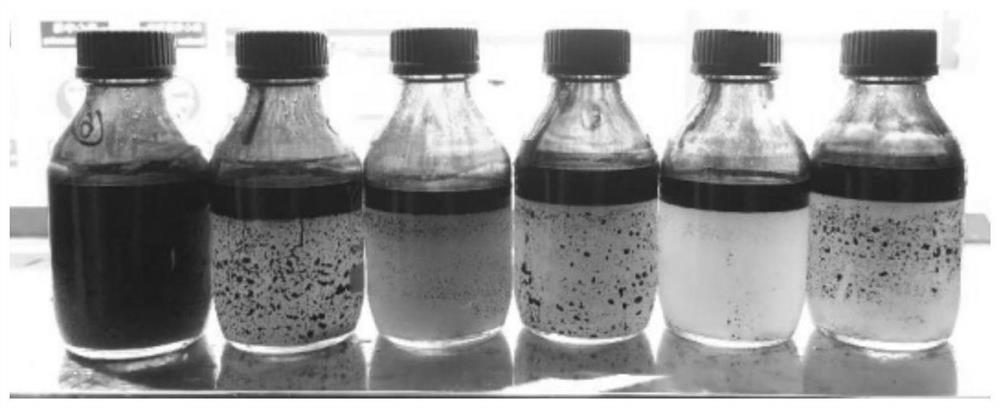

Image

Examples

Embodiment 1

[0032] (1) Add 20g of 2-pyridinemethanol and 3.0g of ring-opening polymerization catalyst potassium hydroxide into the high-temperature and high-pressure reactor, heat up to 90°C, vacuum dehydrate for 30min, continue to heat up to 115-125°C, and gradually introduce 980g of propylene oxide , and control the reaction temperature at 120-140°C and the pressure below 0.4MPa. After the reaction in the kettle reaches negative pressure, keep the reaction at 130°C for 1 hour to obtain polyoxypropylene ether oil head (P1).

[0033] (2) Take 50 g of the polyoxypropylene ether oil head (P1) synthesized in step (1) and place it in a high-temperature and high-pressure reactor, put in 1.95 g of ring-opening polymerization catalyst potassium hydroxide, heat up to 90 ° C, vacuum dehydrate for 30 min, and continue Raise the temperature to 115-125°C, gradually feed 300g of ethylene oxide, and control the reaction temperature to 110-130°C, and the pressure to be lower than 0.4MPa. Oxypropane, con...

Embodiment 2

[0036] (1) Add 20g of 2-pyridineethanol and 3.0g of ring-opening polymerization catalyst sodium hydroxide into a high-temperature and high-pressure reactor, heat up to 90°C, vacuum dehydrate for 30min, continue to heat up to 115-125°C, and gradually introduce 980g of propylene oxide , and control the reaction temperature at 120-140°C and the pressure below 0.4MPa. After the reaction in the kettle reaches negative pressure, keep the reaction at 130°C for 1 hour to obtain polyoxypropylene ether oil head (P2).

[0037] (2) Take 50 g of the polyoxypropylene ether oil head (P2) synthesized in step (1) and place it in a high-temperature and high-pressure reactor, put in 2.1 g of ring-opening polymerization catalyst sodium hydroxide, heat up to 90 ° C, vacuum dehydrate for 30 min, and continue Raise the temperature to 115-125°C, gradually feed 300g of ethylene oxide, and control the reaction temperature to 110-130°C, and the pressure to be lower than 0.4MPa. Propylene oxide, control ...

Embodiment 3

[0040] (1) Add 20g of 4-pyridinepropanol and 3.0g of ring-opening polymerization catalyst barium hydroxide into the high-temperature and high-pressure reactor, heat up to 90°C, vacuum dehydrate for 30min, continue to heat up to 115-125°C, and gradually introduce 980g of epoxy Propane, and control the reaction temperature at 120-140°C and the pressure below 0.4MPa. After the reaction in the kettle reaches negative pressure, keep the reaction at 130°C for 1 hour to obtain polyoxypropylene ether oil head (P3).

[0041] (2) Take 50 g of the polyoxypropylene ether oil head (P3) synthesized in step (1) and place it in a high-temperature and high-pressure reactor, put in 2.1 g of ring-opening polymerization catalyst barium hydroxide, heat up to 90° C., vacuum dehydrate for 30 minutes, and continue Raise the temperature to 115-125°C, gradually feed 300g of ethylene oxide, and control the reaction temperature to 110-130°C, and the pressure to be lower than 0.4MPa. Propylene oxide, cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com