Method for preparing titanium dioxide from high-acidity high-silicon-content titaniferous solution

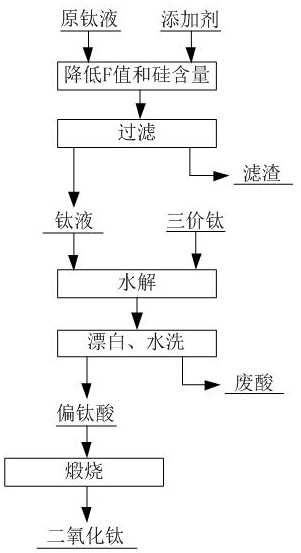

A technology of titanium dioxide and acidity value, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of silicon content in titanium liquid and high acidity value hydrolysis process, etc., achieve low price, wide source, reduce acidity value and silicon content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Slowly add the weighed additive into the water, start stirring at the same time, stir the suspension evenly, the additive mass concentration in the suspension is 30%, then add the suspension into the original titanium liquid until the acidity value of the original titanium liquid drops to 1.83, add After the completion, keep the temperature at 60°C, keep the temperature for 30 minutes, and then cool the titanium liquid at room temperature. During the cooling process, there will be precipitation gradually. After cooling, filter to obtain the filter residue and filtrate. The filtrate is the titanium liquid for subsequent hydrolysis. Add trivalent titanium to the solution to make the mass concentration of trivalent titanium in the titanium solution reach 1.5%, and then hydrolyze it to obtain metatitanic acid by a known titanium solution hydrolysis method. Other conditions in the hydrolysis process are: TiO 2 With a concentration of 187g / L, the obtained metatitanic acid is b...

Embodiment 2

[0036] Slowly add the weighed additive into the water, start stirring at the same time, stir the suspension evenly, the mass concentration of the additive in the suspension is greater than 30%, then add the suspension to the original titanium liquid until the acidity value of the original titanium liquid drops to 1.93, After the addition, keep the temperature at 65°C, keep the temperature for 30 minutes, and then cool the titanium solution at room temperature. During the cooling process, precipitation gradually occurs. After cooling, filter to obtain the filter residue and filtrate. The filtrate is the titanium solution for subsequent hydrolysis. Trivalent titanium is added to the titanium liquid to make the mass concentration of trivalent titanium in the titanium liquid reach 1.0%, and then the metatitanic acid is obtained by hydrolyzing the known titanium liquid hydrolysis method. Other conditions in the hydrolysis process are: TiO 2With a concentration of 197g / L, the obtaine...

Embodiment 3

[0040] Slowly add the weighed additive into the water, start stirring at the same time, stir the suspension evenly, the mass concentration of the additive in the suspension is greater than 30%, then add the suspension to the original titanium liquid until the acidity value of the original titanium liquid drops to 2.03, After the addition, keep the temperature at 60°C, keep the temperature for 30 minutes, and cool the titanium liquid at room temperature. During the cooling process, precipitation gradually precipitates. After cooling, filter to obtain the filter residue and filtrate. The filtrate is the titanium liquid for subsequent hydrolysis. Trivalent titanium is added to the titanium liquid to make the mass concentration of trivalent titanium in the titanium liquid reach 1.5%, and then the metatitanic acid is obtained by hydrolyzing the known titanium liquid hydrolysis method. Other conditions in the hydrolysis process are: TiO 2 With a concentration of 177g / L, the obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com