Wood-grain-imitated quartz stone plate processing device and preparation method thereof

A quartz stone plate and processing device technology, applied in the field of quartz stone, can solve the problem of inability to make plates to offset the user's anxiety, and achieve the effects of continuous automatic production, improving efficiency and preventing uncertainty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

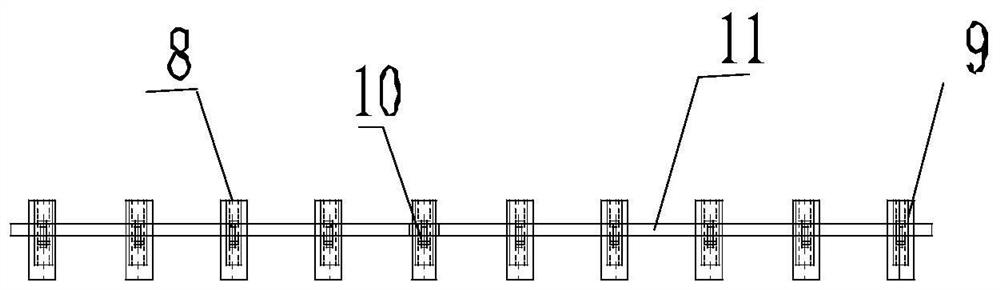

[0059] A processing device for imitating wood-grain quartz stone slabs includes a plow spray device, which is composed of a plow turning device 8, a spray device 9 and a fixed beam 11 carrying the two.

Embodiment 2

[0061]The present embodiment is further limited on the basis of Embodiment 1. The plow turning device 8 is a plurality of coulters arranged in a horizontal array, and the spray device 9 is a spray storage tank connected with an air pressure device; the spray storage tank has multiple Each spray head is connected by a support rod 10 between each spray head and the coulter. The fixed beam 11 is provided with through grooves at intervals; each support rod 10 is fixedly connected with each through groove through pins. Each coulter and spray head are fixedly connected to both ends of the support rod 10 . refer to figure 1

[0062] The coulter group is located on the same side of the support bar 10, and all sprinklers are located on the same side of the coulter group. The coulter is triangular prism type, refer to figure 2 with image 3 The base is an isosceles triangle with a base angle of 60° to 80°. The nozzle is hollow cylindrical, and the nozzle has a rubber hose butt en...

Embodiment 3

[0070] This embodiment provides a method for preparing a wood-like quartz stone plate:

[0071] The steps of its preparation method are:

[0072] A. Preparation of main ingredient 7; B preparation of spray; C processing with plow spray device; D final molding;

[0073] Wherein A includes the following steps:

[0074] A.1 Stir each component material required for main ingredient 7;

[0075] A.2 The required materials are unloaded and dispersed in proportion;

[0076] A.3 The required materials are mixed and stirred;

[0077] A.4 Pre-press the material after mixing;

[0078] A.5 Disperse the rolled materials again;

[0079] A.6 Distribute the dispersed material and pre-press it into the main blank;

[0080] Wherein B includes the following steps:

[0081] B.1 Mix and stir the materials required for the spray;

[0082] B.2 The materials required for the spray are mixed and added to the spray storage tank connected to the external air pressure device;

[0083] Wherein C i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com