Automatic rotating powder distribution device for nozzle of pulsating vacuum jet pump

A pulsating vacuum and automatic rotation technology, which is applied in the directions of fluid mixers, transportation and packaging, mixers, etc., can solve the problems of unstable pulsating state, accelerated decline, etc., and achieve low production cost, avoid lumpy materials, and easy to operate Effect

Active Publication Date: 2019-02-26

TIANJIN UNIV OF SCI & TECH

View PDF8 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The existing defect of above-mentioned technology: the purpose of developing the pulsating vacuum jet pump nozzle powder automatic rotation distributing device is: the jet nozzle has the characteristics of rotatability and asymmetric structure, therefore, it can produce periodically changing pulsating vacuum, while pulsating The vacuum will cause the solid powder to relax and accelerate the unstable pulsation state in the process of entering the jet nozzle, so that the powder can be evenly distributed before entering the jet area, without accumulating into blocks, and the fluidity is good, avoiding "lumping" ", and prevent the jet pump system from running dry, and also prevent the jet nozzle efficiency bottleneck

Therefore, there are obvious defects in the above-mentioned technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

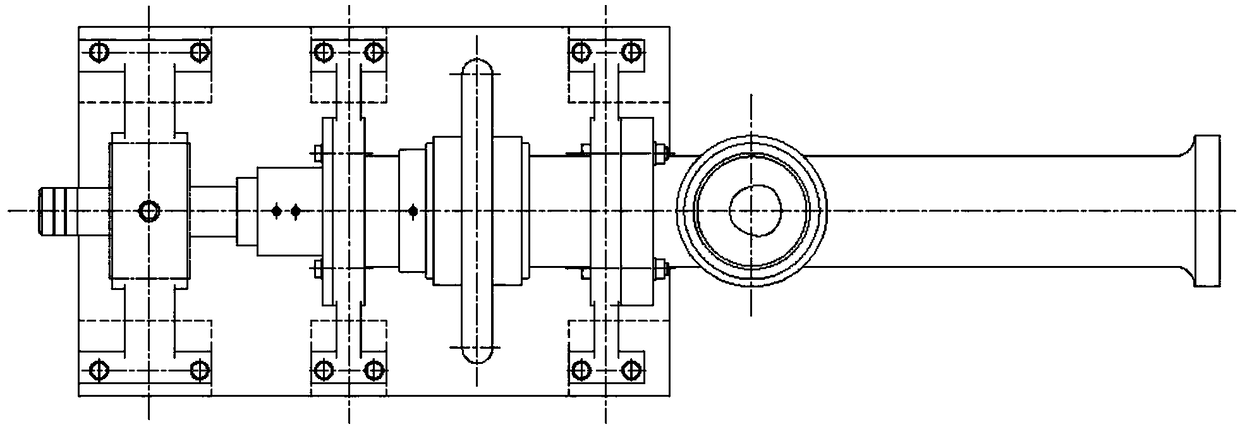

[0027] figure 1 It is a schematic diagram of an economical jet nozzle without a pulsating vacuum jet pump nozzle powder automatic rotating distributing device in the prior art;

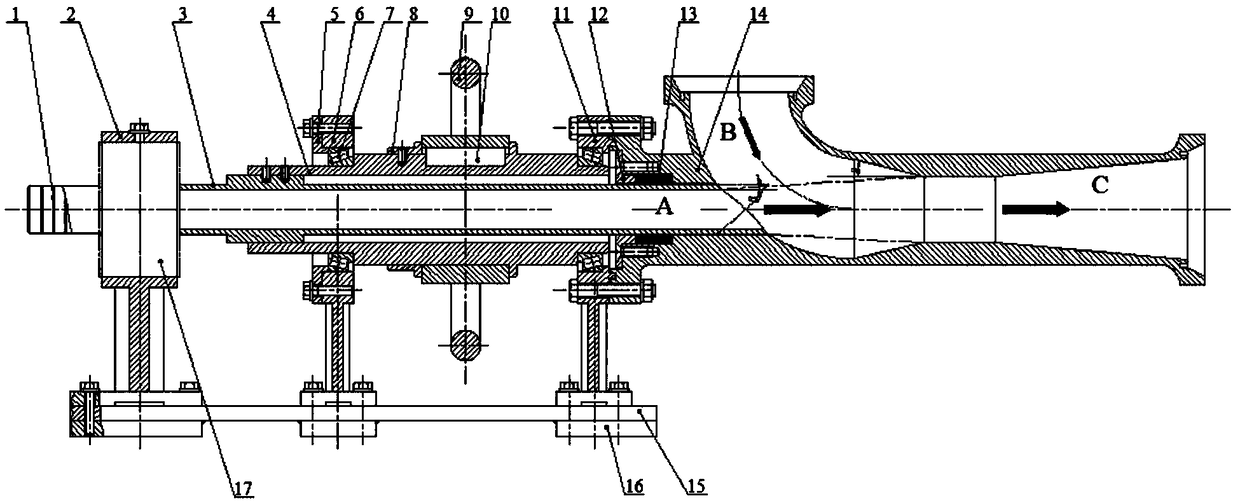

[0028] figure 2 It is a structural schematic diagram of the device of the present invention;

[0029] image 3 yes figure 2 Mid-section bottom view of .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an automatic rotating powder distribution device for a nozzle of a pulsating vacuum jet pump; a left bearing support frame and a right bearing support tube are fixed at the upper end of a fixed plate at intervals; the upper parts of the left bearing support frame and the right bearing support tube are coaxially sleeved and supported with a revolving hollow shaft; the middle part of the revolving hollow shaft is provided with a revolving wheel in a limit manner through a flat key, and the right end of the revolving hollow shaft is coaxially connected with an inlet of apressurization chamber of the nozzle of the jet pump; a jet tube is fixed in the revolving hollow shaft in a coaxially sleeved manner, the right end of the jet tube is inserted in the pressurization chamber connected with the nozzle of the jet pump, and the end port of the right end of the jet tube is of an asymmetrical structure. The jet nozzle of the device has the characteristics of rotatability and asymmetric structure, and can produce pulsating vacuum with periodical change, so that powder can be uniformly distributed before entering a jet area, is not accumulated into blocks, has good fluidity, prevents material heaping and prevents empty operation of the jet pump system.

Description

technical field [0001] The invention belongs to the field of chemical equipment, and relates to a solid-liquid mixed jet pump, in particular to an automatic rotating distributing device for nozzle powder of a pulsating vacuum jet pump. Background technique [0002] The jet pump is an important unit operation in the chemical industry. It is a fluid machinery and mixing conveying reaction equipment that uses the strong shear and violent turbulent diffusion between the high-speed jet and the absorbed fluid to transfer energy and quality. Due to its simple structure, stable process, convenient installation, strong process adaptability, and low production cost, its application range is becoming wider and wider. In some vacuum conditions, the jet pump can replace the water ring type, rotary vane type, Reciprocating vacuum pump. [0003] The research and application of jet pumps have a long history. As early as the 16th century, people discovered the mixing phenomenon of jets. Wi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01F5/02B01F3/12B01F15/02

CPCB01F23/50B01F25/212B01F35/71

Inventor 唐洪涛唐思琪唐洪波卫津泽

Owner TIANJIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com