Workpiece punching and turning-milling integrated machine

An integrated machine and workpiece technology, applied in metal processing machinery parts, manufacturing tools, metal processing, etc., can solve the problems of low processing efficiency and low rate of high-quality finished products, and achieve improved processing efficiency, high-quality rate, and continuous automation The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

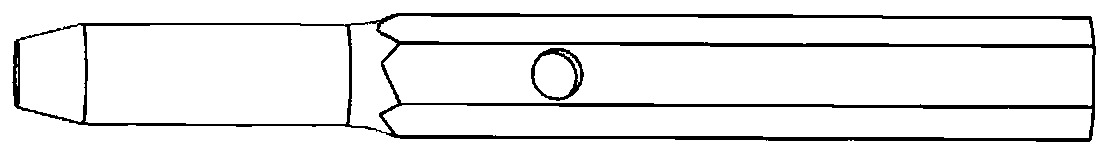

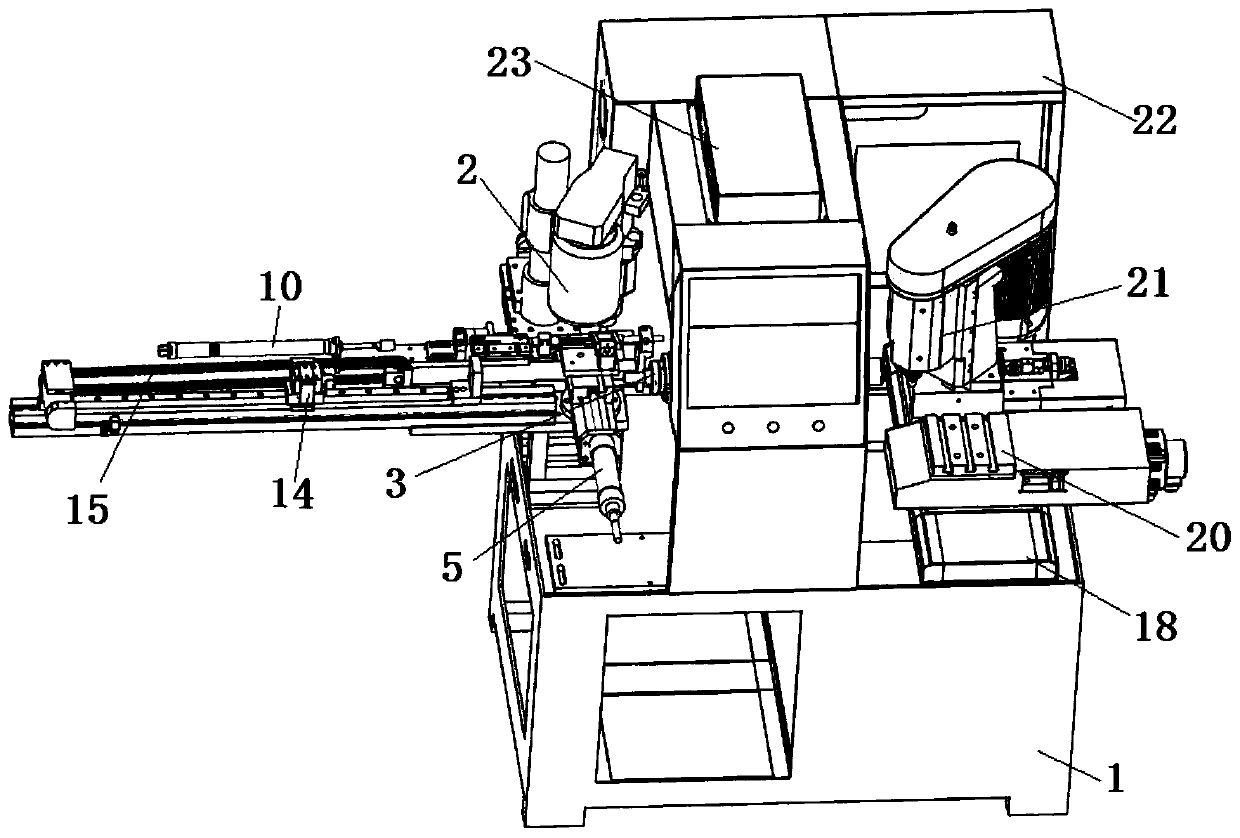

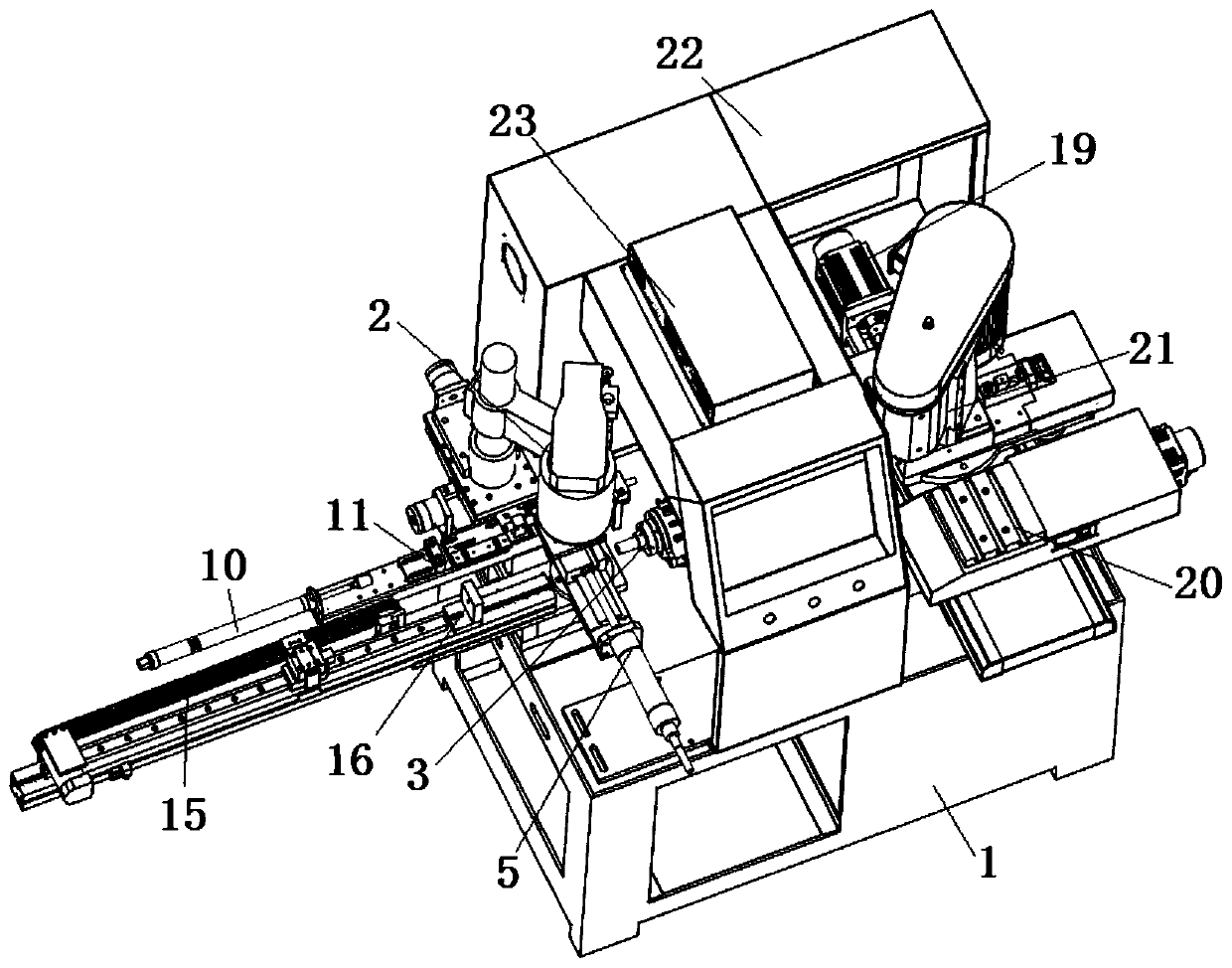

[0021] refer to Figure 2 to Figure 7 Shown: a workpiece punching and turning-milling integrated machine, including a workbench 1, on which a punching mechanism 2 for punching workpieces is fixedly arranged and a spindle 3 is rotated, and the inside of the spindle 3 is arranged along its A feed channel is provided in the axial direction, and the punching mechanism 2 is located on the feed side of the feed channel, and the discharge end of the feed channel is provided with a turning and milling mechanism for turning and milling the workpiece that has been punched; the extension line of the feed channel There is a pusher mechanism set opposite to the turning and milling mechanism on the top, a material transfer station is arranged between the pusher mechanism and the feeding port of the feeding channel, and a punching station is arranged on one side of the transfer station, and the punching mechanism 2 Cooperately arranged in the punching station, a transfer mechanism for transf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com