Grinding method of steel pipe end spiral weld grinding robot

A technology of spiral welding seam and robot, applied in the direction of grinding machine parts, grinding machines, manipulators, etc., can solve the problems of insufficient grinding accuracy, difficult to guarantee machining accuracy, high work cost, and achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0045] The technical scheme of the present invention is as follows: a grinding method for a steel pipe end spiral weld grinding robot, comprising the following steps:

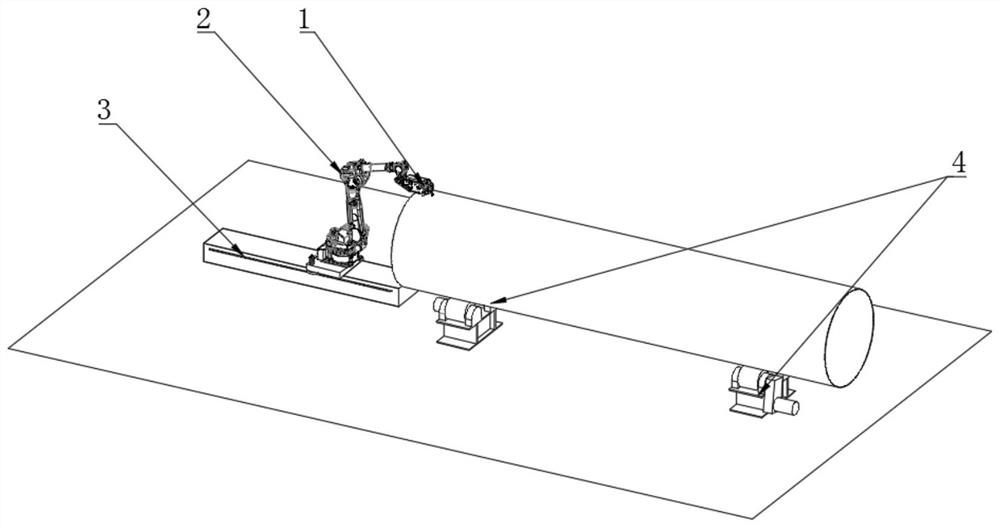

[0046] S1, assembly robot and upload steel pipe parameters: spiral welded pipe end grinding robot includes electrical control system, upper computer and sliding platform 3, according to figure 1 As shown, a mechanical arm 2 is slid on the sliding platform 3, a grinding device 1 is provided on the mechanical arm 2, a profiler 111 and a photoelectric sensor 121 are also provided on the grinding device 1, and the upper computer controls the grinding through the electrical control system. Device 1, mechanical arm 2 and sliding platform 3, input the parameters of steel pipe diameter, wall thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com