A kind of processing method of coating pipe

A processing method and pipe material technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve problems such as complex processing, barbs on layers, sundries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

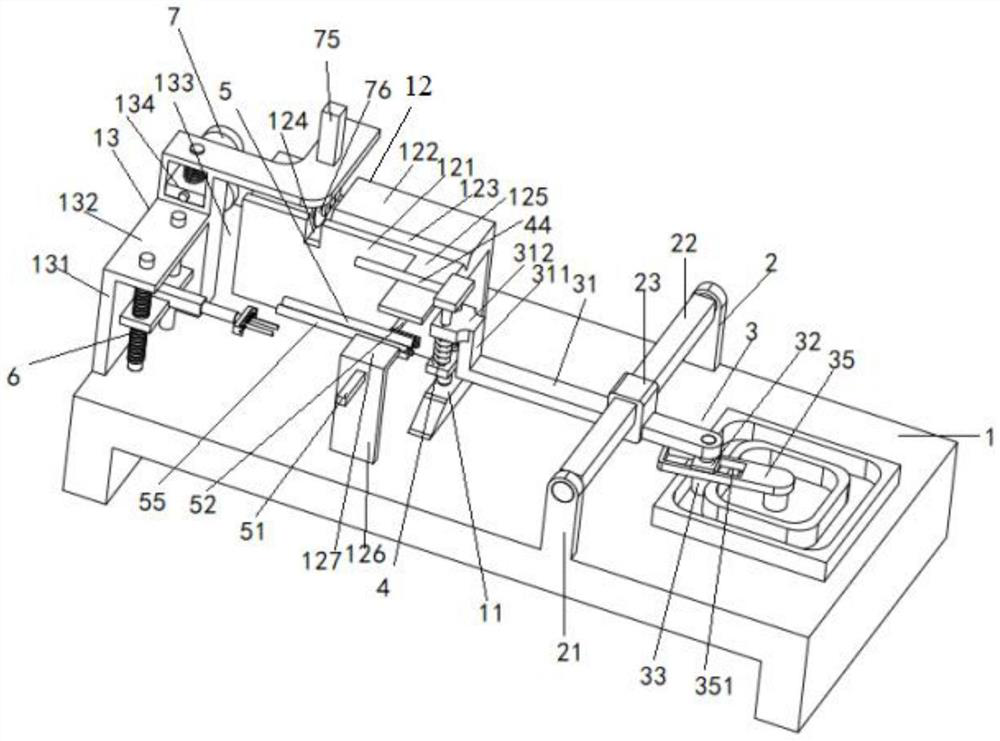

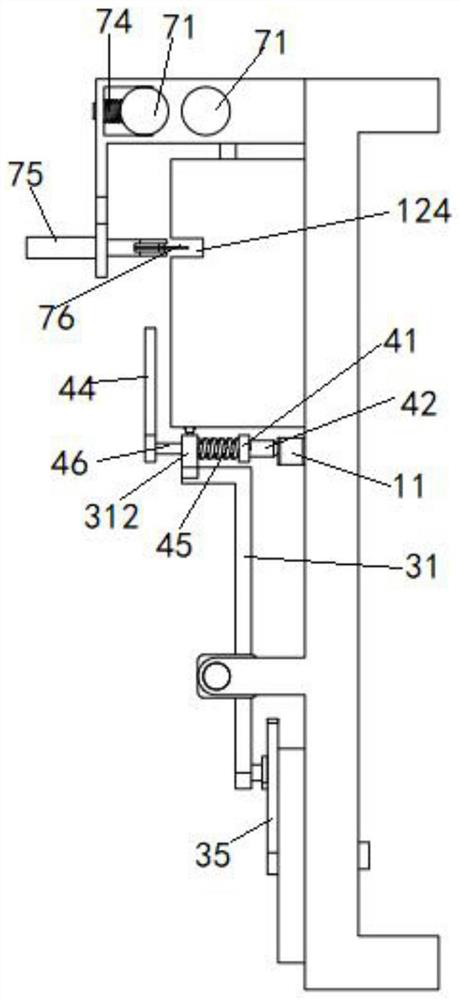

[0034] The coated pipe is processed by an integrated pipe cutting and grinding device, which can be cut according to the required length and then ground at the same time, so as to realize the integrated processing process, such as Figure 1-6 As shown in the figure, the integrated pipe cutting and grinding device used in the processing includes a support table 1, a support sliding mechanism 2 is arranged in the middle of the surface of the support table 1, a limit rotation pulling mechanism 3 is arranged on the right side of the surface, and a limit rotation pulling mechanism 3 The elastic pipe transmission mechanism 4 is installed on the upper surface, and the left side of the surface of the support table 1 is respectively provided with a positioning member 11, a cut-off support conversion table 12 and an adjustment fixing table 13 from right to left. Mechanism 5, one side of the adjustment fixing table 13 is provided with a clamping and rotating mechanism 6, while the other s...

Embodiment 2

[0045] A processing method of a coated pipe is as follows:

[0046] The first step is to insert the pipe to be processed between the two transmission wheels 71. At this time, the upper transmission wheel 71 moves upward due to the support of the pipe, so that the second spring is compressed, and then the fifth reduction motor and the sixth reduction are controlled. The motors work at the same time, and the two transmission wheels 71 drive the pipe to move through friction. The pipe extends into the V-shaped placement groove 123 and moves along the V-shaped placement groove 123 until it extends a certain distance and then controls the fourth hydraulic cylinder 75 to drive The cutting piece 76 moves downward, and then controls the rotation of the seventh reduction motor to realize the cutting of the pipe by the cutting piece 76;

[0047] The second step is to control the rotation of the first deceleration motor to drive the rotating rod 35 to rotate. During the rotation of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com