Fluorosilicate porous hybrid material as well as preparation method and application thereof

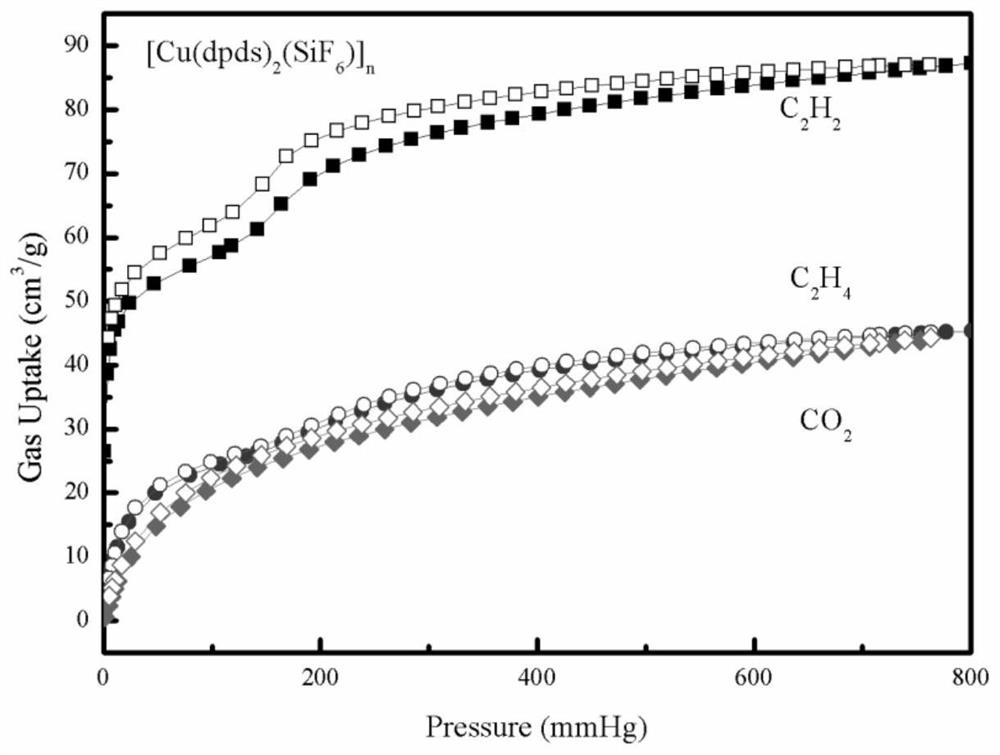

A technology of fluorosilicate and copper fluorosilicate is applied in the field of fluorosilicate porous hybrid materials and their preparation, which can solve the problems of high energy consumption and high cost, and achieve large adsorption capacity, enhanced identification, and separation selectivity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Dissolve 54mg of 4,4'-dipyridyl disulfide in 2mL of methanol for 25min by ultrasonic (power 100W) vibration. Add 2 mL of copper hexafluorosilicate solution dropwise at a rate of 0.1 mL / s while stirring, the concentration of copper hexafluorosilicate solution is 0.1 mol / L, copper hexafluorosilicate and 4,4'-dipyridyl The molar ratio of disulfide is 1:1 (slight excess of ligand). The resulting mixed solution was continuously stirred at 25° C. for 72 h. After the reaction was completed, the mixture was filtered to obtain a blue powder, which was washed three times with anhydrous methanol to obtain a fluorosilicate porous hybrid material product.

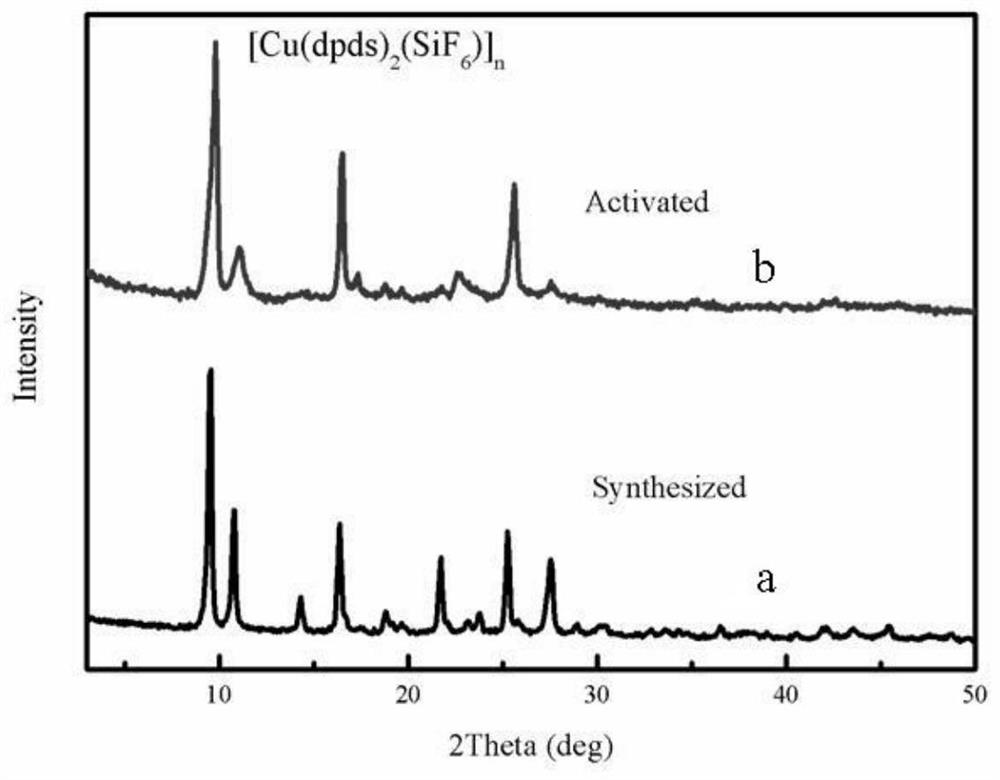

[0034]Activation treatment to remove the guest solvent in the framework: first, the freshly synthesized fluorosilicate porous hybrid material product powder sample was subjected to at least 8 solvent exchanges with dry methanol within two days, and then on the Micromeritics ASAP 2020 instrument, at 50 ° C Vacuum for 24 hours unt...

Embodiment 2

[0043] Dissolve 54mg of 4,4'-dipyridyl disulfide in 2mL of methanol for 30 minutes by ultrasonic (power 80W) vibration. Add 2 mL of copper hexafluorosilicate solution dropwise at a rate of 0.05 mL / s while stirring, the concentration of copper hexafluorosilicate solution is 0.2 mol / L, copper hexafluorosilicate and 4,4'-dipyridyl The molar ratio of disulfide is 1:1.5 (slight excess of ligand). The resulting mixed solution was continuously stirred at 50° C. for 24 h. After the reaction, the mixture was filtered to obtain a blue powder, which was washed three times with anhydrous methanol to obtain a fluorosilicate porous hybrid material product.

Embodiment 3

[0045] Dissolve 54mg of 4,4’-dipyridyl disulfide in 2mL of methanol for 20min by ultrasonic (power 120W) vibration. Add 2 mL of copper hexafluorosilicate solution dropwise at a rate of 0.2 mL / s while stirring, the concentration of copper hexafluorosilicate solution is 0.15 mol / L, copper hexafluorosilicate and 4,4'-dipyridyl The molar ratio of disulfide is 1:2 (slight excess of ligand). The resulting mixed solution was continuously stirred at 35° C. for 48 h. After the reaction was completed, the mixture was filtered to obtain a blue powder, which was washed three times with anhydrous methanol to obtain a fluorosilicate porous hybrid material product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com