Sinusoidal or trapezoidal counter potential five-phase permanent magnet motor short-circuit fault-tolerant control method adopting dead-beat current tracking

A permanent magnet motor, current tracking technology, applied in motor generator control, electronic commutation motor control, motor control and other directions, can solve the problems of fault-tolerant control error, not making full use of the third harmonic space of five-phase motor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

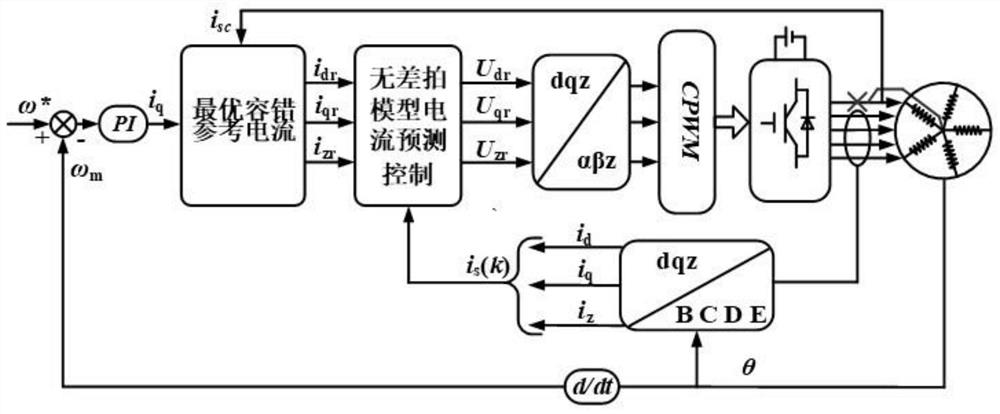

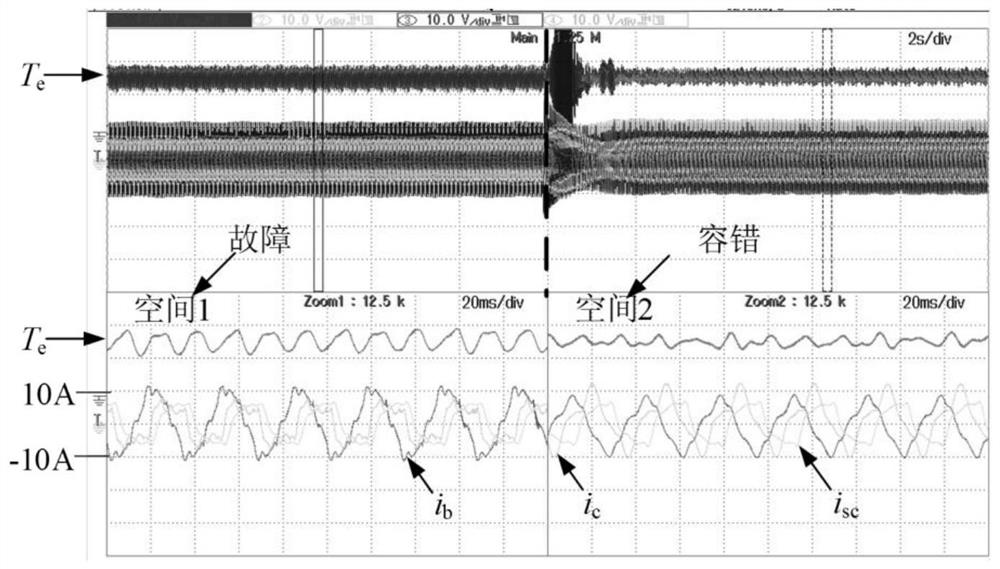

[0088]The invention discloses a short-circuit fault-tolerant control method for a five-phase permanent magnet motor with sinusoidal or trapezoidal back-EMF using deadbeat current tracking. The method includes the following steps: detecting the motor speed, and setting a given speed ω*And actual feedback speed ωmFor comparison, use the PI controller to get the given current i of the motor q-axisq; Using the given current i of the q-axisq, Through the torque expressions in the fundamental space and the third harmonic space, the reference current i for maintaining the output torque is obtainedd1o , Iq1o , Iz1o , Id3o , Iq3o , Iz3o ; To suppress the torque ripple caused by the short-circuit current as the goal, the short-circuit current isc Related short-circuit suppression current id1s , Iq1s , Iz1s , Id3s , Iq3s , Iz3s ; Superimpose the reference current to maintain the output torque and the short-circuit suppression current in their respective spaces, and finally integrate them into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com