Network-based electromechanical equipment operating system and method

A technology for electromechanical equipment and operating systems, applied in general control systems, control/regulation systems, electrical program control, etc., can solve problems involving shallow depth, inability to realize cloud remote control, and insufficient project pertinence, so as to achieve control intelligence optimization, improve scalability and adaptability to various working conditions, and realize the effect of self-optimization function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

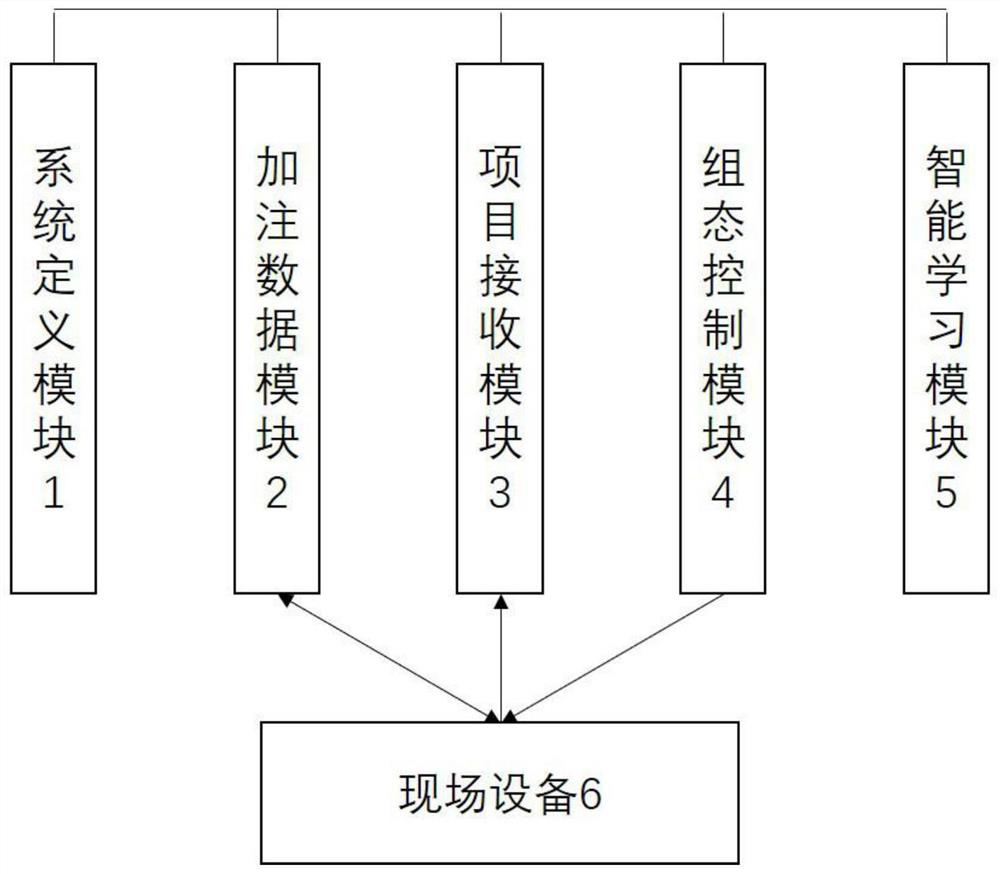

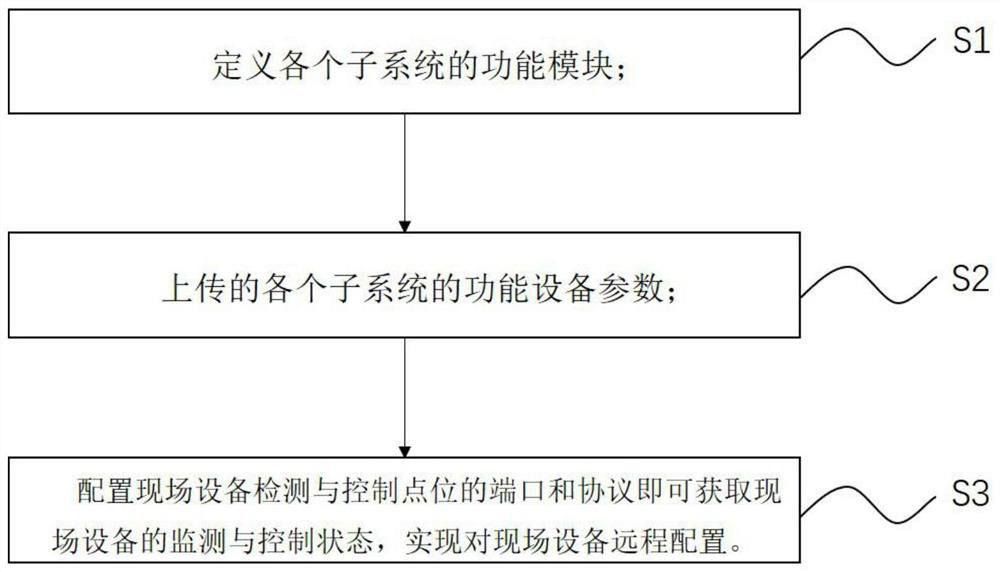

[0029] The invention provides a network-based electromechanical equipment operating system and method. Its working principle is to monitor the field devices of the functional modules of each subsystem in real time by defining the functional modules of each subsystem, and realize remote monitoring of the field devices through the network. Configuration to achieve the purpose of improving project pertinence, not depending on local hardware devices and systems, flexible remote control, improving scalability and adaptability to various working conditions.

[0030] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

[0031] like figure 1 As shown, the electromechanical equipment operating system based ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com