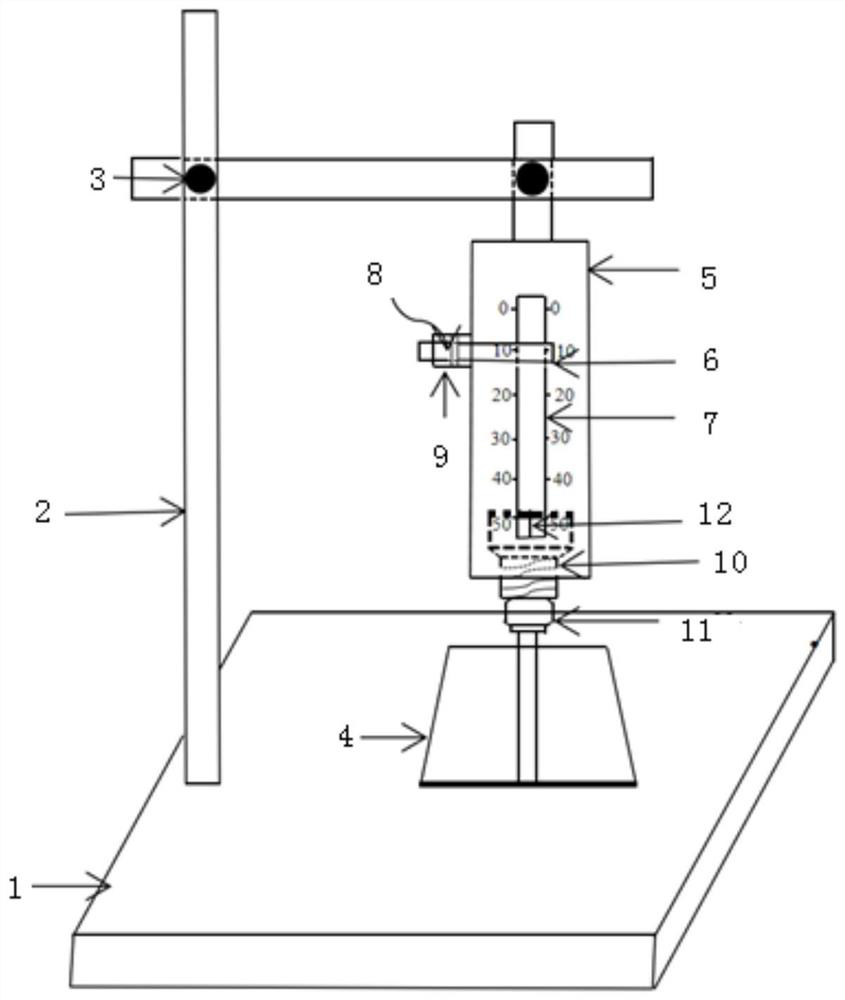

Device and method for measuring consistency of extrusion type 3D printing medical ceramic slurry

A ceramic slurry, 3D printing technology, applied in the field of 3D printing, can solve the problems of waste of raw materials and increase the investment of man-hours, and achieve the effect of easy observation and easy data reading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0059] The test method for the consistency of medical ceramic slurry for extrusion 3D printing, including the following steps:

[0060] Select medical ceramic powder beta tricalcium phosphate (β-TCP) and hydroxyapatite (HA), use polyvinyl alcohol (PVA) aqueous solution as binder, and use a homogenizer ZYMC-580V to mix an appropriate amount of ceramic powder ( HA:β-TCP=3:2) and PVA aqueous solution with a concentration of 12% were stirred evenly, wherein the mass ratio of ceramic powder to PVA was 9:1.

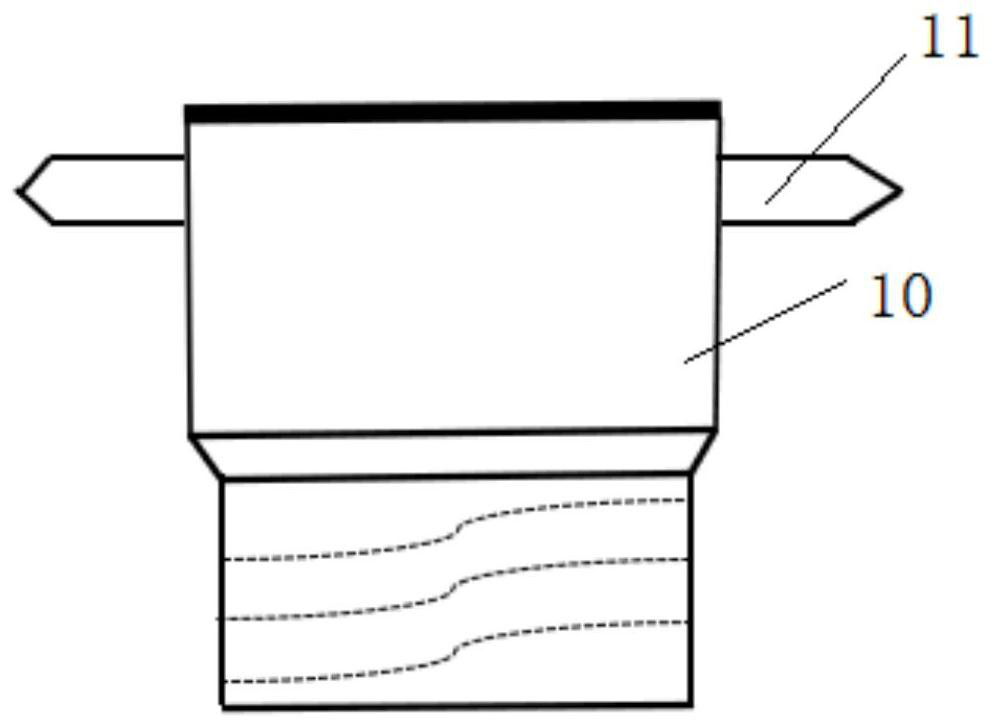

[0061] Step 1, put the evenly stirred ceramic slurry into the volumetric flask 4, divide into three times, vibrate each 1 / 3 by hand several times to make the surface of the ceramic slurry smooth.

[0062] Step 2, after the third charging is completed, one side of the angled scraper is tilted to be flush with the surface of the ceramic slurry, and the surface of the ceramic slurry is scraped flat. Adjust the upper and lower positions of the magnet so that the solid needle is fl...

Embodiment example 2

[0068] The test method for the consistency of extruded 3D printing ceramic slurry includes the following steps:

[0069] Select medical ceramic powder β-TCP, HA, and PVA aqueous solution as the binder, and use a homogenizer to stir an appropriate amount of ceramic powder (HA:β-TCP=3:2) and a PVA aqueous solution with a concentration of 12%. Wherein the mass ratio of ceramic powder and PVA is 8:1.

[0070] Step 1, put the stirred ceramic slurry into the bottom-capped volumetric flask 4, divide it into three packages, vibrate 1 / 3 of each package several times by hand to make the surface of the ceramic slurry smooth.

[0071] Step 2 After the third charging is completed, one side of the angled scraper is tilted to be flush with the surface of the ceramic slurry, and the surface of the ceramic slurry is scraped. Adjust the upper and lower positions of the magnet so that the solid needle is flush with the surface of the ceramic slurry and read the scale value corresponding to the ...

Embodiment example 3

[0077] The test method for the consistency of medical ceramic slurry for extrusion 3D printing, including the following steps:

[0078] Select medical ceramic powder β-TCP, HA, and PVA aqueous solution as the binder, and use a homogenizer to stir an appropriate amount of ceramic powder (HA:β-TCP=3:2) and a PVA aqueous solution with a concentration of 12%. Wherein the mass ratio of ceramic powder and PVA is 7:1.

[0079] Step 1, put the stirred ceramic slurry into a volumetric flask, divide into three fillings, vibrate 1 / 3 of each filling several times by hand to make the surface of the ceramic slurry smooth.

[0080] Step 2, after the third charging is completed, one side of the angled scraper is tilted to be flush with the surface of the ceramic slurry, and the surface of the ceramic slurry is scraped flat. Adjust the upper and lower positions of the magnet so that the solid needle is flush with the surface of the ceramic slurry and read the scale value corresponding to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com