High-temperature tensile test method for high-strength low-alloy weather-resistant structural steel

A high-strength, low-alloy, weathering structural steel technology, applied in the testing of machine/structural components, strength characteristics, and testing of mechanical components, etc. problems, to achieve consistent data results, simple and convenient test methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment provides a high-temperature tensile test method for the tensile strength of high-strength low-alloy weather-resistant structural steel, specifically: when the material undergoes a relatively long work-hardening condition, select the speed change when the displacement reaches 5% of the length of the parallel section ; The length of the parallel section is 30mm; the shifting position is 1.5mm;

[0023] Further, the test temperature of the tensile test is 650°C;

[0024] Using SHIMADZU AG-X250KN testing machine;

[0025] Further, the displacement rate of the beam before yielding is 0.15 mm / min, and the displacement rate of the beam after yielding is 2.5 mm / min.

[0026] Further, the high-strength low-alloy weather-resistant structural steel is: S355J2W.

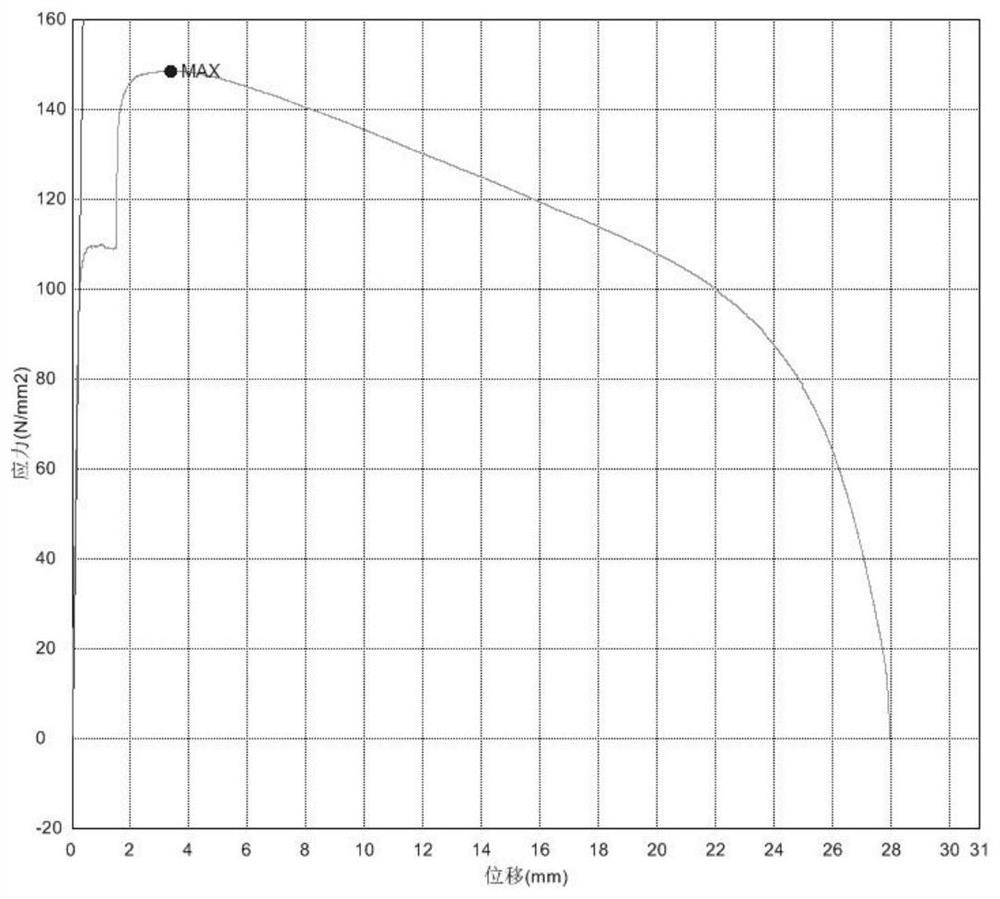

[0027] see figure 1 , it can be observed that the tensile strength value R obtained by changing the speed at this position m It is 148MPa, and changing the test rate at this position will obtain a sta...

Embodiment 2

[0029] This embodiment provides a high-temperature tensile test method for the tensile strength of high-strength low-alloy weather-resistant structural steel, specifically: when the material undergoes a relatively long work-hardening condition, the speed change is selected when the displacement reaches 8.3% of the length of the parallel section ; The length of the parallel section is 30mm; the shifting position is 2.5mm;

[0030] Further, the test temperature of the tensile test is 650°C;

[0031] Using SHIMADZU AG-X250KN testing machine;

[0032] Further, the displacement rate of the beam before yielding is 0.15 mm / min, and the displacement rate of the beam after yielding is 2.5 mm / min.

[0033] Further, the high-strength low-alloy weather-resistant structural steel is: S355J2W.

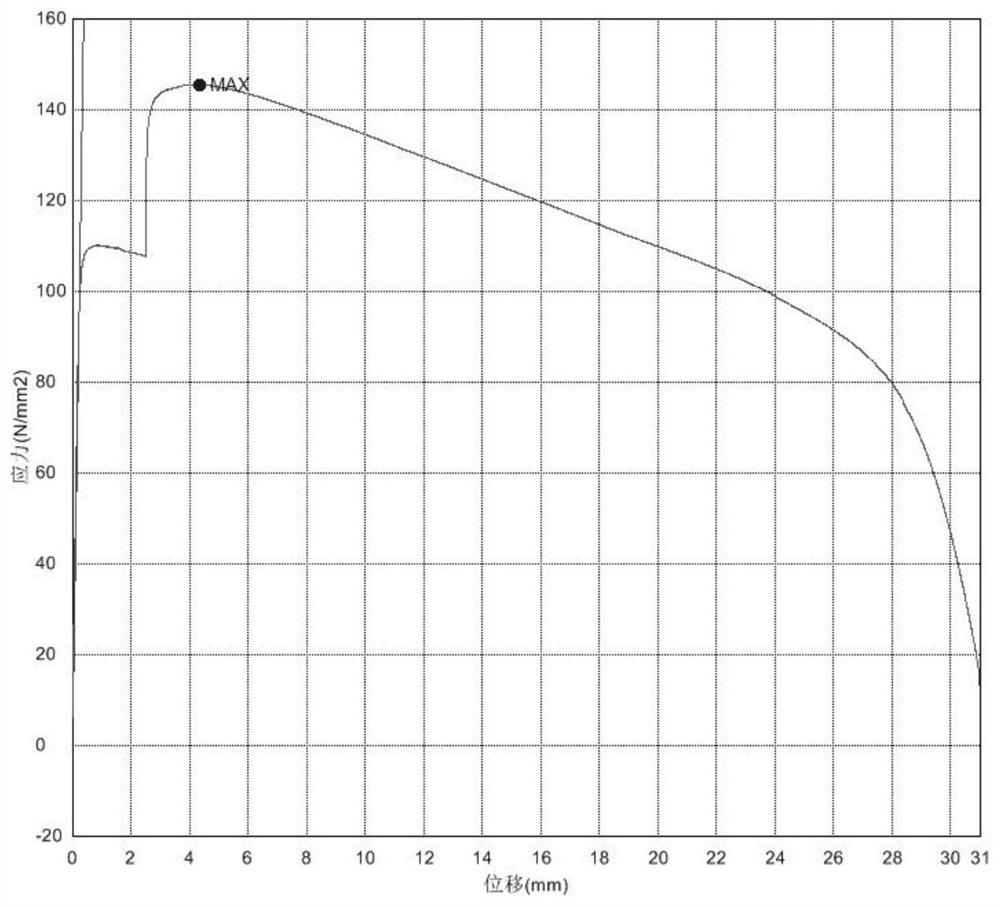

[0034] see figure 2 , it can be observed that the tensile strength value R obtained by changing speed at this position m It is 145MPa, and changing the test rate at this position will obtain a ...

Embodiment 3

[0036] This embodiment provides a high-temperature tensile test method for the tensile strength of high-strength low-alloy weather-resistant structural steel, specifically: when the material undergoes a relatively long work-hardening condition, select to change the speed when the displacement reaches 10% of the length of the parallel section; The length of the parallel section is 30mm; the shift position is 3.0mm;

[0037] Further, the test temperature of the tensile test is 650°C;

[0038] Using SHIMADZU AG-X250KN testing machine;

[0039] Further, the displacement rate of the beam before yielding is 0.15 mm / min, and the displacement rate of the beam after yielding is 2.5 mm / min.

[0040] Further, the high-strength low-alloy weather-resistant structural steel is: S355J2W.

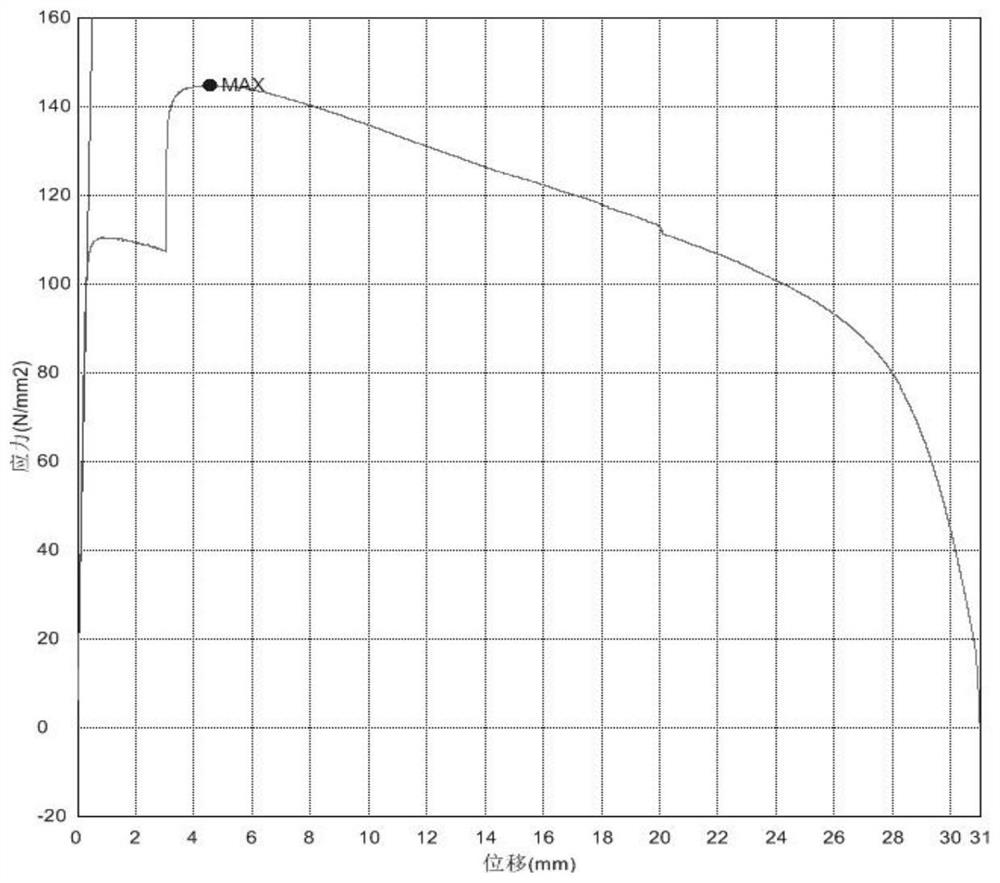

[0041] see image 3 , it can be observed that the tensile strength value R obtained by changing speed at this position m It is 145MPa, and changing the test rate at this position will obtain a stable a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com