Refrigeration control method and device and refrigeration equipment

A refrigeration equipment and refrigeration control technology are applied in the fields of devices, refrigeration equipment, and refrigeration control methods to achieve the effects of being less prone to frost formation, reducing frost formation, and avoiding performance loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a refrigeration control method, which can effectively reduce frosting of refrigeration equipment and improve refrigeration energy efficiency and reliability.

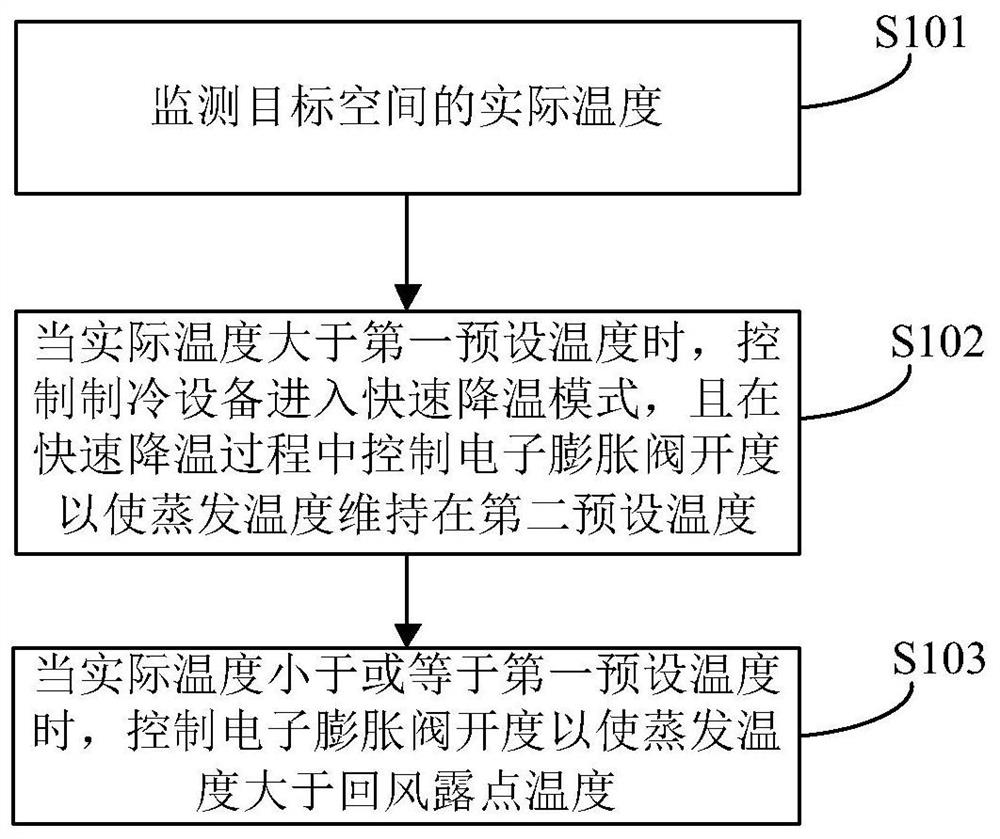

[0046] figure 1 It is a flow chart of the refrigeration control method provided in Embodiment 1 of the present invention, as shown in figure 1 As shown, the method includes the following steps:

[0047] S101. Monitor the actual temperature of the target space.

[0048] S102. When the actual temperature is greater than the first preset temperature, control the refrigeration device to enter the rapid cooling mode, and control the opening of the electronic expansion valve during the rapid cooling process to maintain the evaporation temperature at the second preset temperature.

[0049] S103. When the actual temperature is less than or equal to the first preset temperature, control the opening of the electronic expansion valve so that the evaporation temperature is greater than the dew poin...

Embodiment 2

[0072] The above refrigeration control method will be described below in conjunction with a specific embodiment, however, it should be noted that this specific embodiment is only for better illustrating the present application and does not constitute an improper limitation to the present application. Explanations of terms that are the same as or corresponding to those in the foregoing embodiments will not be repeated in this embodiment.

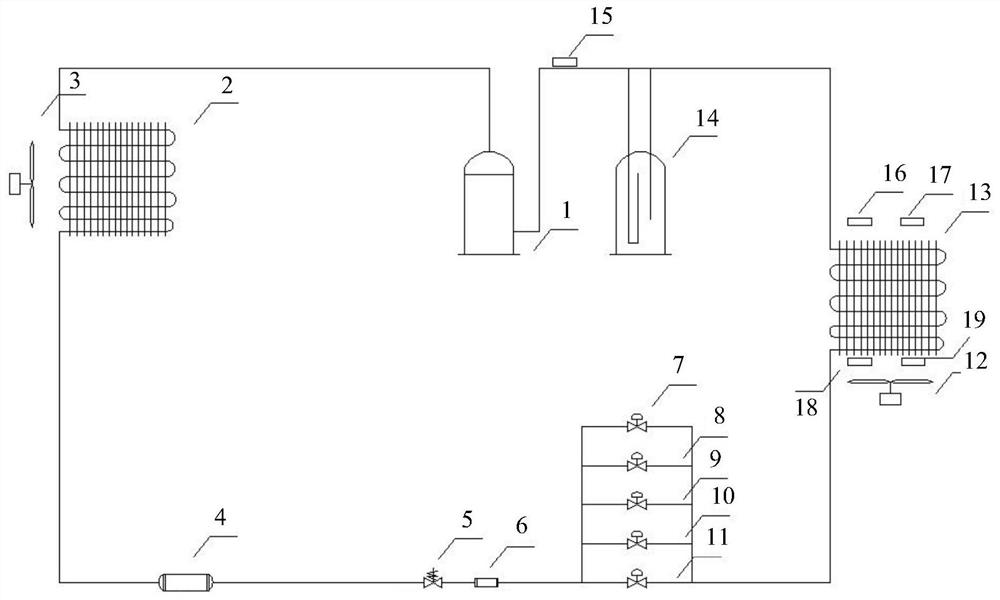

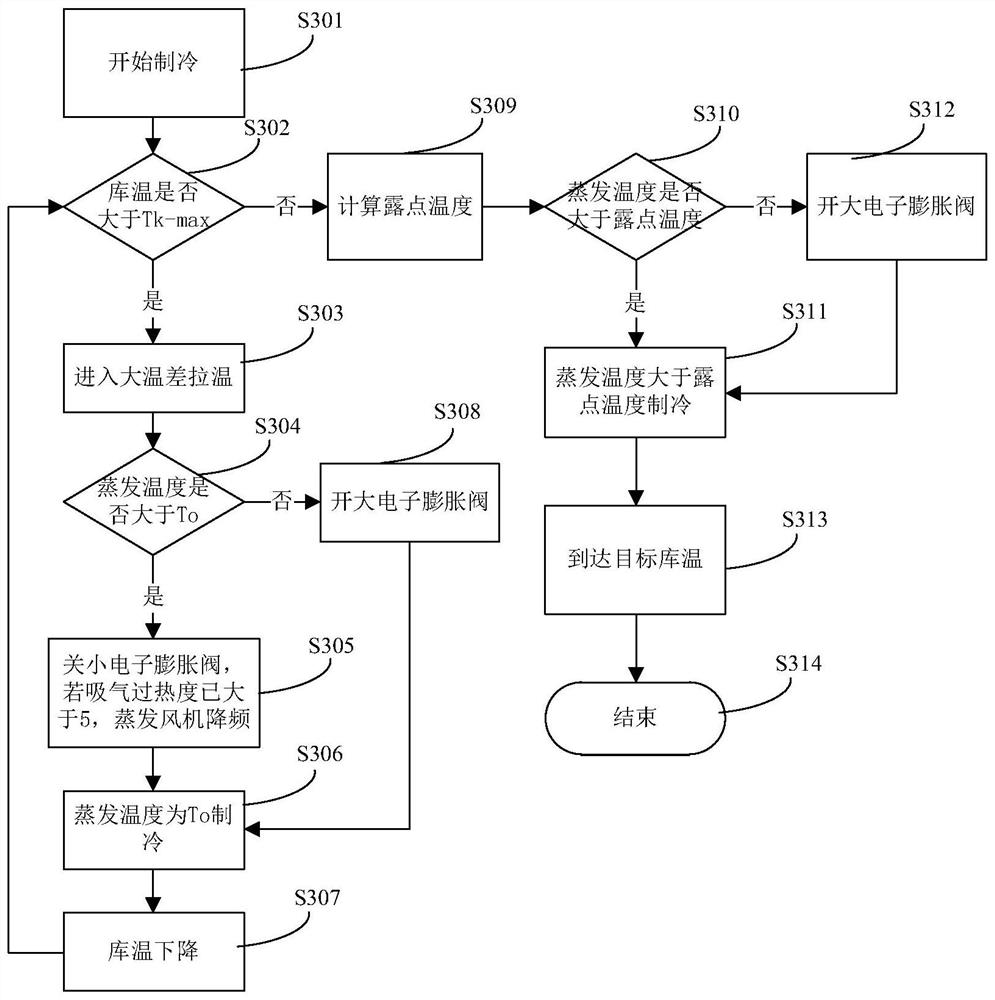

[0073] combine figure 2 refrigeration unit shown, refer to image 3 , taking the cold storage unit as an example, the refrigeration control method to reduce frosting includes the following steps:

[0074] S301, start refrigeration.

[0075] S302. Determine whether the storage temperature is greater than Tk-max (that is, the first preset temperature), if yes, go to step S303, if not, go to step S309.

[0076] S303, controlling the cold storage unit to enter a temperature pulling state with a large temperature difference.

[0077] S304, ju...

Embodiment 3

[0096] Based on the same inventive concept, this embodiment provides a refrigeration control device, which can be used to implement the refrigeration control method described in the above embodiments. The device can be realized by software and / or hardware, and generally the device can be integrated into the controller of the refrigeration equipment.

[0097] Figure 4 It is a structural block diagram of the refrigeration control device provided by Embodiment 3 of the present invention, as shown in Figure 4 As shown, the device includes:

[0098] A monitoring module 41, configured to monitor the actual temperature of the target space;

[0099] The first control module 42 is used to control the refrigeration equipment to enter the rapid cooling mode when the actual temperature is greater than the first preset temperature, and control the opening of the electronic expansion valve during the rapid cooling process to maintain the evaporation temperature at the second preset temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com