Active chilled beam air conditioner terminal

An air-conditioning terminal and active technology, applied in air-conditioning systems, heating methods, space heating and ventilation, etc., can solve the problems of flow velocity obstruction, reduce the risk of infection, increase the fresh air volume, etc., achieve stable air outlet direction and reduce infection Risk, the effect of increasing the fresh air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

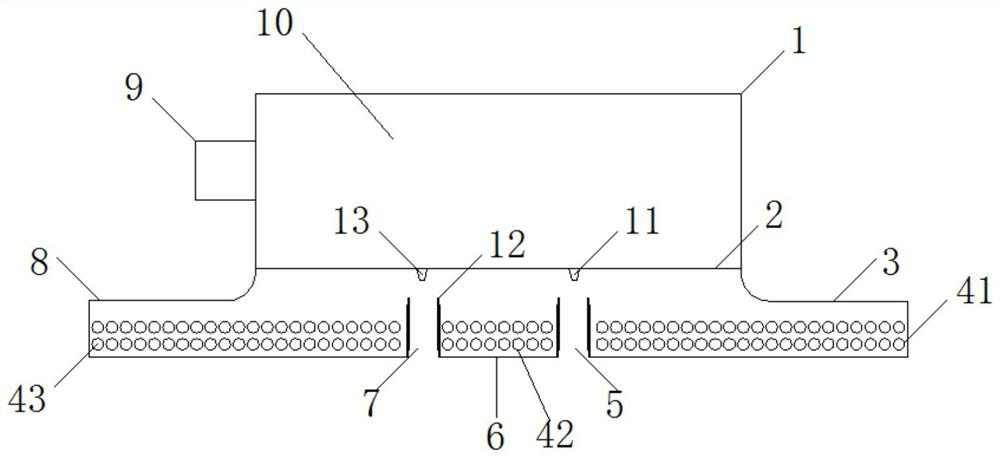

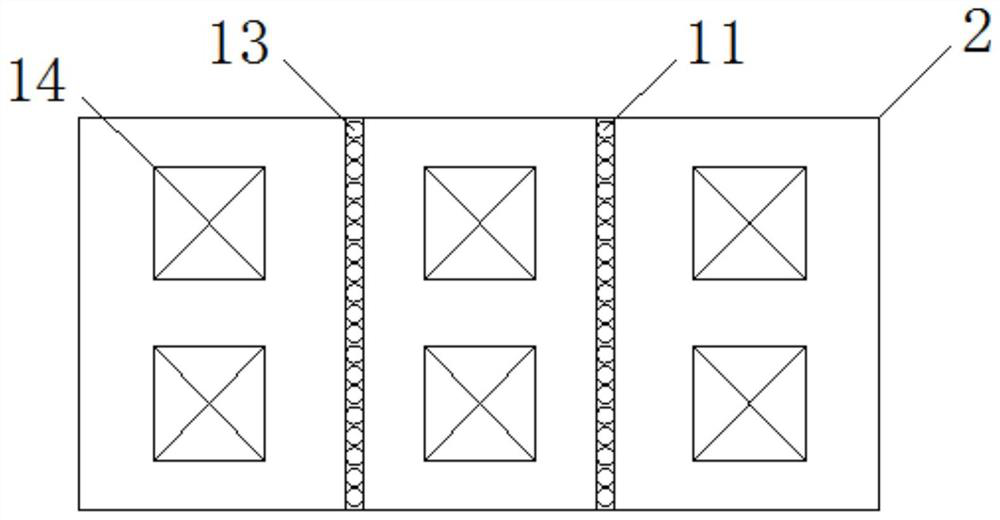

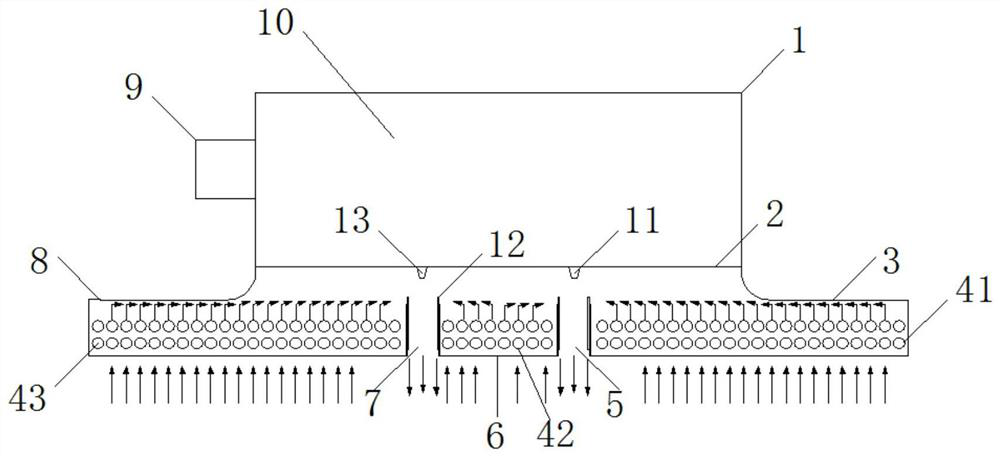

[0023] Such as figure 1 and figure 2 As shown, the embodiment of the present application provides an active chilled beam air conditioner terminal, which includes a box body, and the box body includes an outer box 1, an inner box 6, a left side box 8 and a right side box 3, and the left side The box 8, the inner box 6 and the right box 3 are sequentially arranged under the outer box 1 and the lower ends of the left box 8, the inner box 6 and the right box 3 are flush, and the outer box 1 is connected with a circular Air supply pipe 9, a static pressure chamber 10 is formed in the outer box 1, the outer box 1 is connected to the left and right side boxes, and the right side box 3, the inner box 6 and the left side box 8 are sequentially provided with the first A heat exchanger 41 , a second heat exchanger 42 and a third heat exchanger 43 . The treated primary air is sent into the static pressure chamber 10 through the circular air supply pipe 9 , and then ejected through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com