An improved spunbond device, forming method and split-release bicomponent filament-based microfiber material

A technology of ultra-fine fiber and molding method, which is applied in the direction of ultrasonic/sonic fiber processing, textile and papermaking, fiber chemical characteristics, etc., and can solve the problem of non-woven materials that are difficult to balance the relationship between green preparation process, medical protection characteristics and flexibility, etc. problems, to achieve the effects of high fiber opening rate, wide application fields, and environmental protection output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

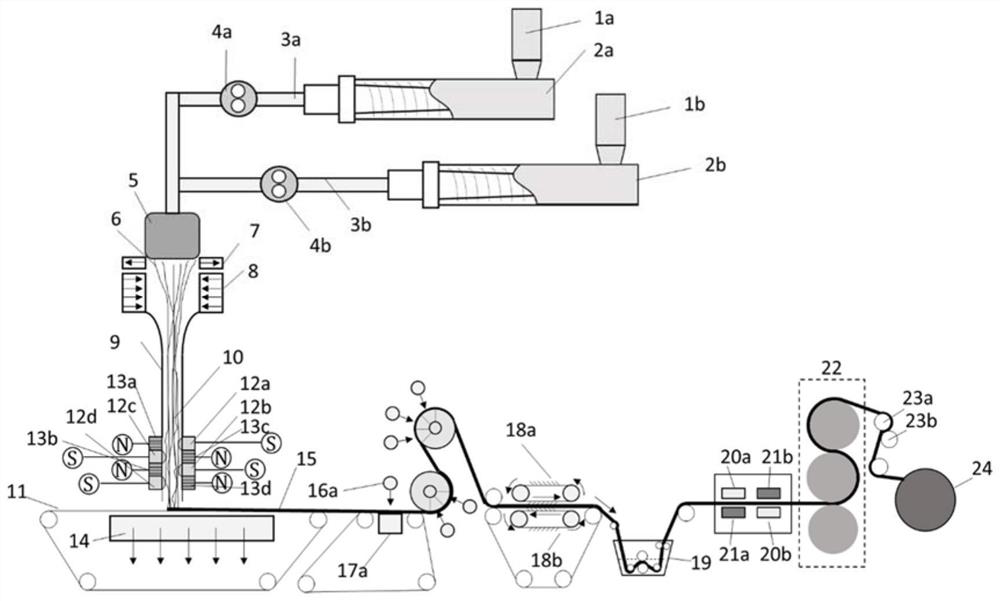

[0054] A method for forming a split-type two-component filament-based ultrafine fiber material, the forming process is as follows figure 1 As shown, the steps are as follows:

[0055] (1) Preparation process of magnetic electret particles

[0056] First, ferric iron tetroxide powder with an average particle size of 500nm and polytetrafluoroethylene with an average particle size of 300nm were physically blended at a mass ratio of 1:2 to form magnetic electret particles.

[0057] Then the magnetic electret particles and polyester chips (Sinopec Tianjin Branch) are sent into the granulator with a mass ratio of 5:95 to obtain magnetic electret particles / polyester chips;

[0058] (2) The preparation process of split-off type virgin silk

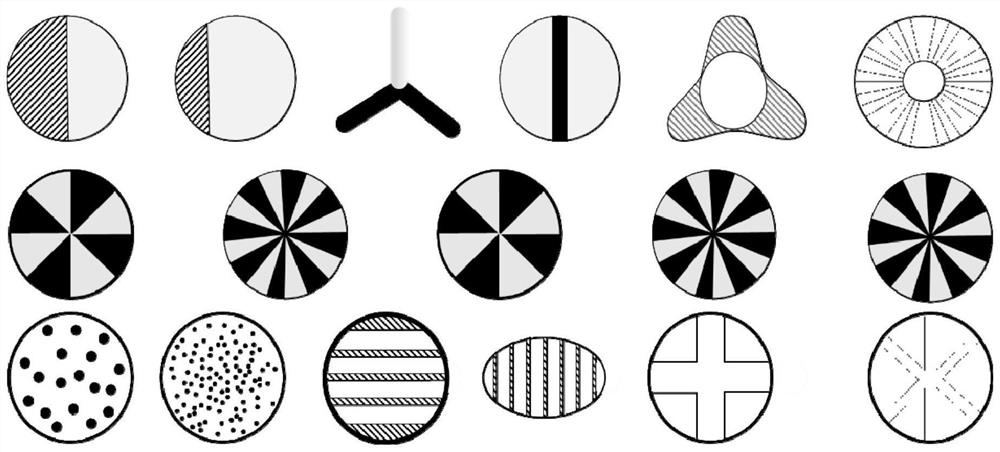

[0059] The magnetic electret particles / polyester chips (SDN301, Sinopec Tianjin Branch) described in step 1, polyamide chips (Zhejiang Longcheng Chemical Fiber Co., Ltd.) and polyolefin elastomers (7050FL, Exec Sen Mobil Chemical Industry) acco...

Embodiment 2

[0077] A method for forming a split-type two-component filament-based superfine fiber material, the steps are as follows:

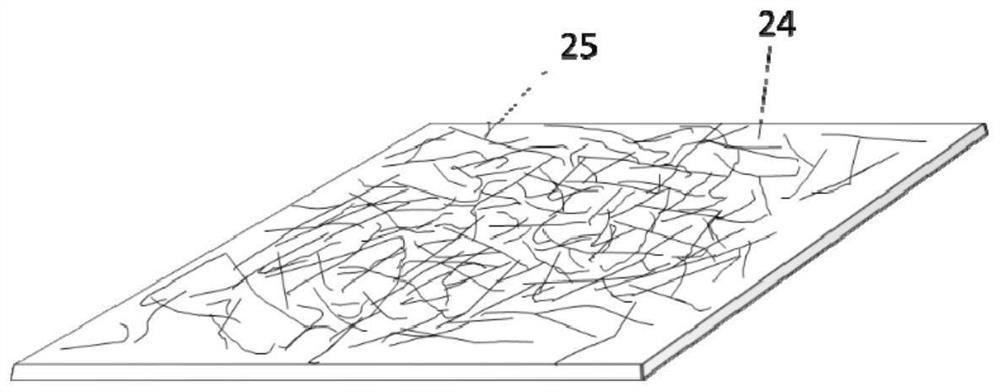

[0078] The preparation method of this embodiment is the same as the preparation method of Example 1, the difference is that the ferric iron tetroxide powder is replaced with 300nm cobalt tetraoxide powder, and the spinning assembly is replaced with a hollow-orange segment (32 petals) to obtain a split Release-type two-component filament-based microfiber material, see the surface of the sample Figure 9 .

[0079] It is 46.8g / m to prepare density by utilizing the splitting type two-component filament-based superfine fiber material of the present embodiment 2 The two-component filament microfiber nonwoven material with medical protective properties, the test results of its characteristics are shown in Table 1.

Embodiment 3

[0081] A method for forming a split-type two-component filament-based ultrafine fiber material, the steps are as follows: The preparation method of this embodiment is the same as that of Example 1, the difference is that polyester chips are replaced by polylactic acid chips ( 6252D, NatureWorks), polyamide slices are replaced by polyolefin elastomer slices, and polytetrafluoroethylene is replaced by hindered amine additives; Figure 5 The tilting power of B makes the split-type two-component filament-based ultrafine fiber material.

[0082] It is 98.9g / m to prepare the surface density by utilizing the split-type two-component filament-based ultrafine fiber material of the present embodiment 2 The two-component filament microfiber nonwoven material with medical protective properties, the test results of its characteristics are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com