High-strength and high-conductivity copper-tin alloy contact wire and preparation process thereof

A copper-tin alloy and preparation process technology, applied in conductive materials, conductive materials, metal/alloy conductors, etc., can solve the problems of easy burnout, limited application, low strength, etc., achieve high strength and conductivity, and broaden applications. Scope, effect of refining precipitates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

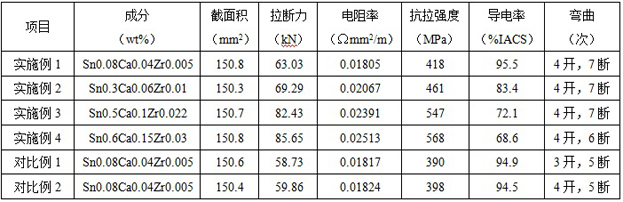

Examples

Embodiment 1

[0032] A high-strength and high-conductivity copper-tin alloy contact wire, the chemical composition of the copper-tin alloy contact wire is: Sn 0.08wt%, Ca 0.04wt%, Zr 0.005wt%, the balance is Cu and unavoidable impurities; The chemical composition of the copper-tin alloy contact wire is prepared by sequentially adding Cu, Sn, Ca, and Zr in batches.

[0033] A preparation process for a high-strength and high-conductivity copper-tin alloy contact wire, specifically comprising the following steps:

[0034] (1) Add electrolytic copper to the smelting furnace for smelting, and add charcoal and graphite flake covering agent. The smelting temperature is controlled at 1190°C.

[0035] (2) Then add pure tin for smelting, and the smelting temperature is controlled at 1160°C.

[0036] (3) Add Cu-Ca and Cu-Zr intermediate alloys in turn for melting, and the melting temperature is controlled at 1100°C.

[0037] (4) CuSn prepared in step (3) 0.08 Ca 0.04 Zr 0.005 The temperature of t...

Embodiment 2

[0043] A high-strength and high-conductivity copper-tin alloy contact wire, the chemical composition of the copper-tin alloy contact wire is: Sn 0.30wt%, Ca 0.06wt%, Zr 0.01wt%, the balance is Cu and unavoidable impurities; The chemical composition of the copper-tin alloy contact wire is prepared by sequentially adding Cu, Sn, Ca, and Zr in batches.

[0044] According to the process steps (1)-(8) of Example 1, a high-strength and high-conductivity copper-tin alloy contact wire is obtained, wherein the upward lead speed in step (4) is 220mm / min, and the diameter of the upward lead copper rod is 23mm; step (5) Extruded into an extruded alloy rod with a diameter of 24mm.

Embodiment 3

[0046] A high-strength and high-conductivity copper-tin alloy contact wire, the chemical composition of the high-strength and high-conductivity copper-tin alloy contact wire consists of: Sn 0.50wt%, Ca 0.1wt%, Zr 0.02wt%, the balance is Cu and non Impurities to be avoided: the chemical composition of the copper-tin alloy contact wire is prepared by sequentially adding Cu, Sn, Ca, and Zr in batches.

[0047] According to the process steps (1)-(8) of Example 1, a high-strength and high-conductivity copper-tin alloy contact wire is obtained, wherein the upward lead speed in step (4) is 220mm / min, and the diameter of the upward lead copper rod is 23mm; step (5) Extruded into an extruded alloy rod with a diameter of 28mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com