A high-coverage, wash-resistant, one-pass waterborne interior paint

A washing-resistant and interior wall paint technology, applied in the direction of coating, can solve the problems of high cost, insufficient fullness, cracking of roller coating, etc., achieve stable storage and transportation, excellent fullness and leveling, and improve The effect of scrub resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

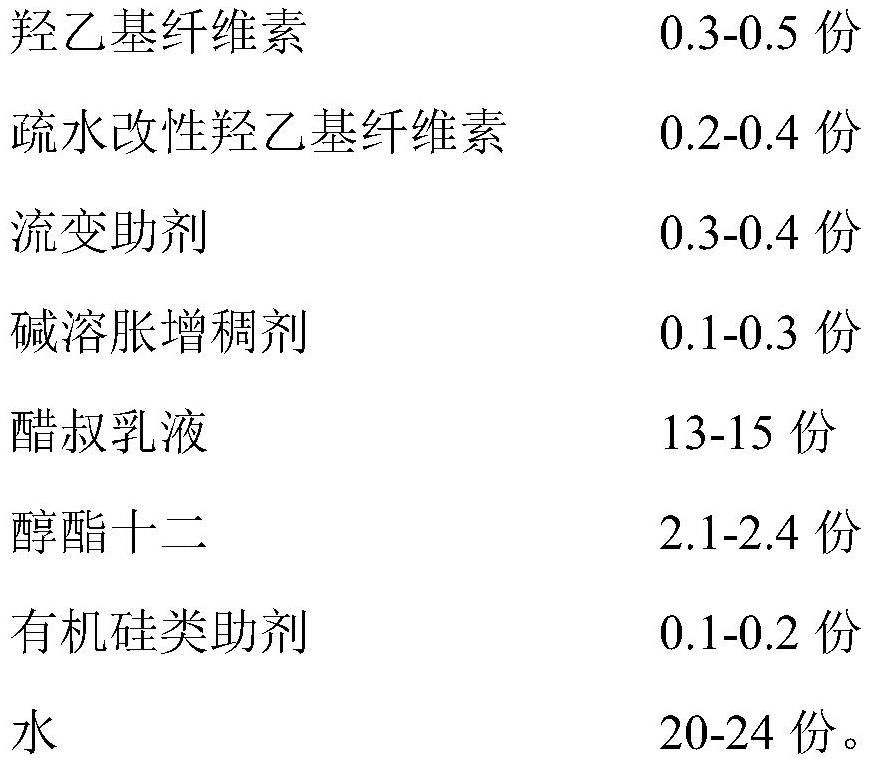

[0032] A water-based interior wall paint with high covering and washability, which comprises the following components in parts by mass:

[0033]

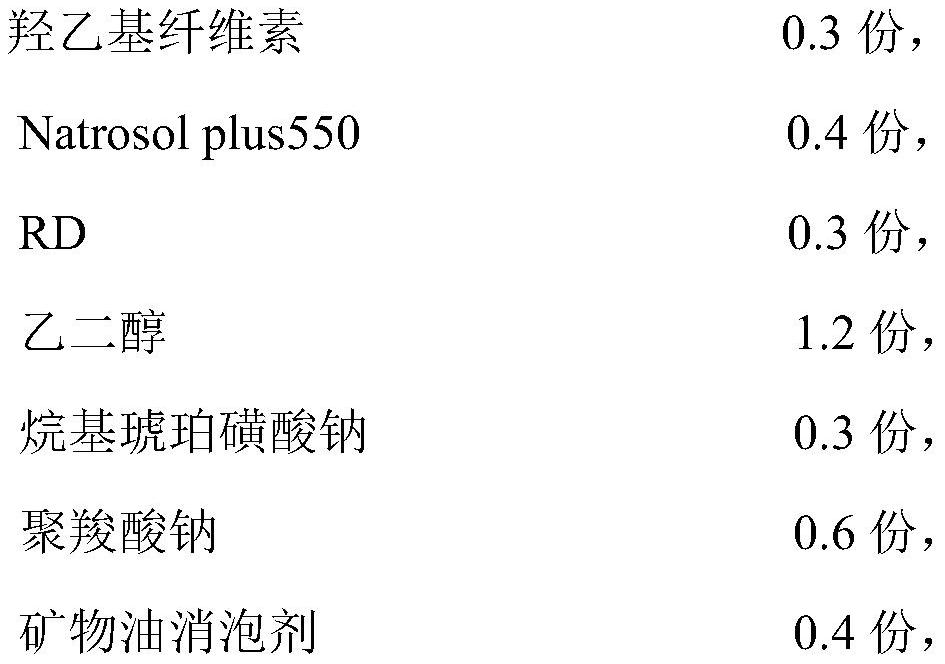

[0034]

[0035] The preparation method of the above-mentioned high-coverage and scrub-resistant one-time application of water-based interior wall paint comprises the following steps:

[0036] (1) According to the above mass parts, add hydroxyethyl cellulose, Natrosol plus550 and RD into water and mix well, then slowly add ethylene glycol, 2-amino-2-methyl-1-propanol, mineral oil in sequence Defoamer, wetting agent sodium alkyl succinate, dispersant sodium polycarboxylate, stir and disperse evenly at 500r / min;

[0037] (2) Then slowly add titanium dioxide, heavy calcium carbonate and calcined kaolin according to the above-mentioned parts by mass, and stir and disperse evenly at 2000r / min;

[0038] (3) Then, according to the above mass parts, slowly add tert-vinegar emulsion, stir and disperse evenly at 900r / min, then add alcoh...

Embodiment 2

[0040] A water-based interior wall paint with high covering and washability, which comprises the following components in parts by mass:

[0041]

[0042]

[0043] The preparation method of the above-mentioned high-coverage and scrub-resistant one-time application of water-based interior wall paint comprises the following steps:

[0044] (1) According to the above mass parts, add hydroxyethyl cellulose, Natrosol plus550 and RD into water and mix well, then slowly add ethylene glycol, 2-amino-2-methyl-1-propanol, mineral oil in sequence Defoamer, wetting agent sodium alkyl succinate, dispersant sodium polycarboxylate, stir and disperse evenly at 800r / min;

[0045] (2) Then slowly add titanium dioxide, ground calcium carbonate and calcined kaolin according to the above-mentioned parts by mass, and stir and disperse evenly at 2500r / min;

[0046] (3) Then, according to the above mass parts, slowly add tert-vinegar emulsion, stir and disperse evenly at 900r / min, then add alco...

Embodiment 3

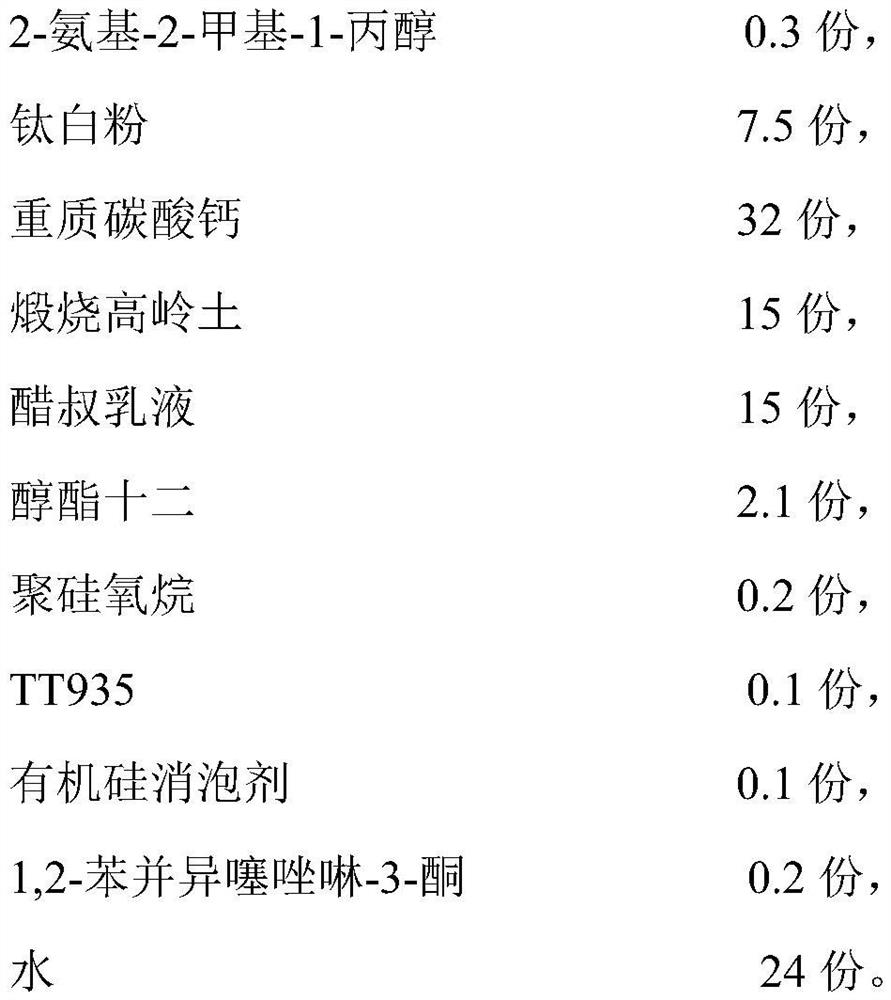

[0048] A water-based interior wall paint with high covering and washability, which comprises the following components in parts by mass:

[0049]

[0050]

[0051] The preparation method of the above-mentioned high-coverage and scrub-resistant one-time application of water-based interior wall paint comprises the following steps:

[0052](1) According to the above mass parts, add hydroxyethyl cellulose, Natrosol plus550 and RD into water and mix well, then slowly add ethylene glycol, 2-amino-2-methyl-1-propanol, mineral oil in sequence Defoamer, wetting agent sodium alkyl succinate, dispersant sodium polycarboxylate, stir and disperse evenly at 650r / min;

[0053] (2) Then slowly add titanium dioxide, ground calcium carbonate and calcined kaolin according to the above-mentioned parts by mass, and stir and disperse evenly at 1500r / min;

[0054] (3) Then, according to the above mass parts, slowly add tert-vinegar emulsion, stir and disperse evenly at 900r / min, then add alcoh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com