High-speed railway ballastless track convex blocking table filling material and preparation method thereof

A ballastless track and high-speed railway technology, applied in building insulation materials, building components, buildings, etc., to achieve excellent fatigue resistance, maintain stability, and improve low-temperature and cold-resistant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

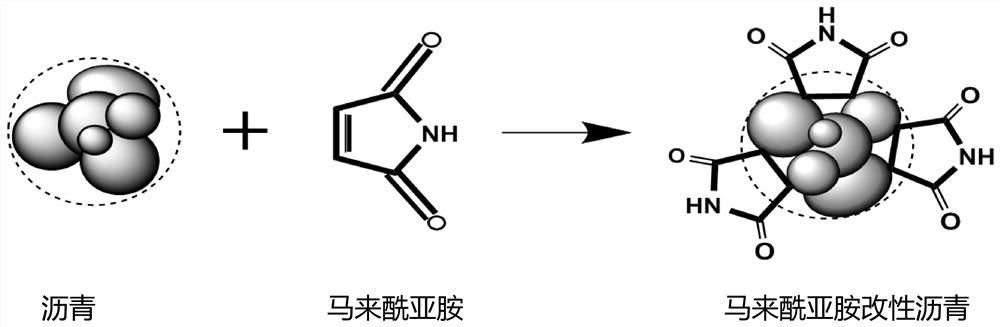

[0040] The preparation method of component A maleimide modified asphalt: heat the reactor to 140°C, add some common base asphalt (US Shell), and add maleimide accounting for 2.50% of the mass of the base asphalt, and heat up to 155°C, maintain the pressure at 0.5MPa, and react for 180 minutes to obtain maleimide-modified asphalt;

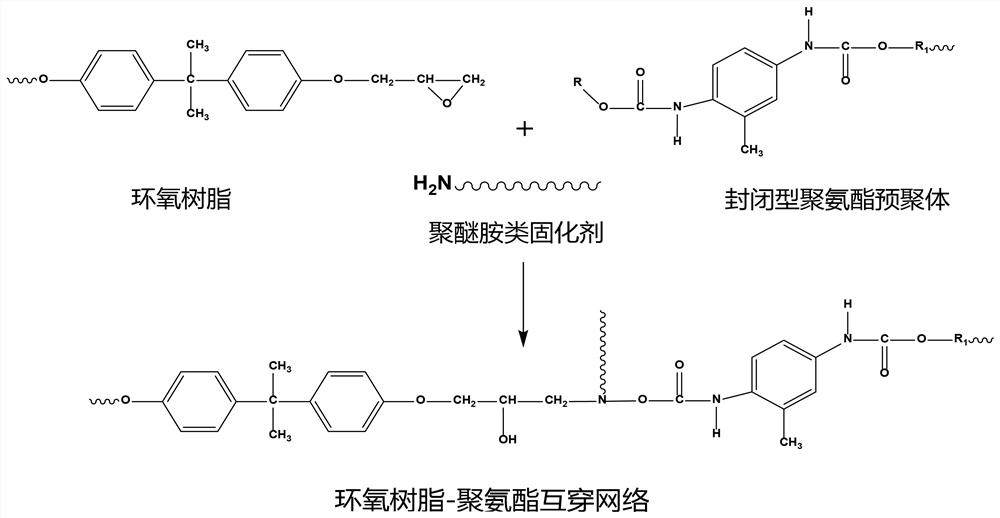

[0041] Component B is liquid epoxy resin (E51, produced by Nanya Resin Factory);

[0042] The preparation method of component C blocked polyurethane prepolymer is as follows: heat the reactor to 70°C, add toluene and polyurethane prepolymer HKR-6776 into the reactor according to the mass ratio of 1:0.5, and feed N 2 Protect until it is completely dissolved, then add the toluene solution of methyl ethyl ketoxime (1:2 by mass ratio) dropwise into the reaction kettle equipped with polyurethane prepolymer, after 6.5 hours of reaction, stop the reaction, and remove it by distillation under reduced pressure at 70°C Solvent, detect the discharge, and obta...

Embodiment 2

[0053] The preparation method of component A maleimide modified asphalt is as follows: heat the reactor to 120°C, add some common base asphalt (Qilu Petrochemical), and at the same time add maleimide accounting for 8.0% of the mass of the base asphalt, and raise the temperature To 160°C, maintain the pressure at 0.45MPa, and react for 210 minutes to obtain maleimide-modified asphalt;

[0054] Component B is epoxy resin (E51, produced by Yueyang Petrochemical);

[0055] The preparation method of component C blocked polyurethane prepolymer refers to Example 1, the difference is that the polyurethane prepolymer is HKR-6786, the blocking agent is phenol, and the reaction time is 6.5 hours;

[0056] C component epoxy resin curing agent, by weight, consists of the following raw materials:

[0057] 100 parts of polyetheramine curing agent (among them, SURFONAMINE ® B60, JEFFAMINE ® M2070, JEFFAMINE® T5000, mixed uniformly according to the molar ratio of 1:0.54:0.32), blocked polyu...

Embodiment 3

[0066] The preparation method of component A maleimide modified asphalt is as follows: heat the reaction kettle to 110°C, add some ordinary base asphalt (origin: Shanjiasi), and add 3.65% maleimide in the base asphalt at the same time, Raise the temperature to 150°C, maintain the pressure at 0.35MPa, and react for 240 minutes to obtain maleimide-modified asphalt;

[0067] Component B is epoxy resin (E51, Jinan Tianmao);

[0068] The preparation method of component C blocked polyurethane prepolymer refers to Example 1, the difference is that the polyurethane prepolymer is HC-6692, the blocking agent is diethyl malonate, and the reaction time is 8 hours;

[0069] C component epoxy resin curing agent, by weight, consists of the following raw materials:

[0070] 100 parts of polyetheramine curing agent (among them, JEFFAMINE® M1000, JEFFAMINE ® XTJ-436, JEFFAMINE ® T500, SURFONAMINE ® B200, mixed uniformly according to the molar ratio of 1:0.34:0.55:0.40), 35.1 parts by weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com