Reinforcing layer rubber as well as preparation method and application thereof

A reinforcement layer and rubber technology, applied in the reinforcement layer of pneumatic tires, vehicle parts, tire parts, etc., can solve problems such as poor batch stability, achieve high batch stability, prevent molecular chain breakage, and heat generation. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

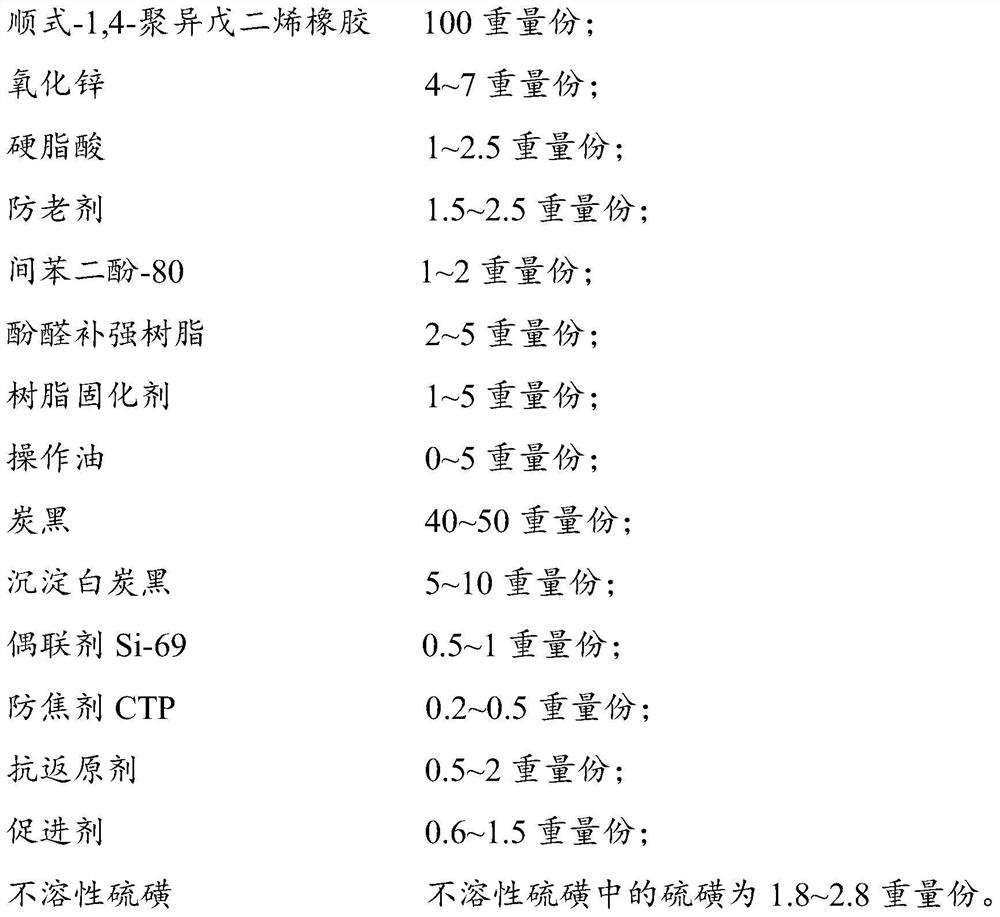

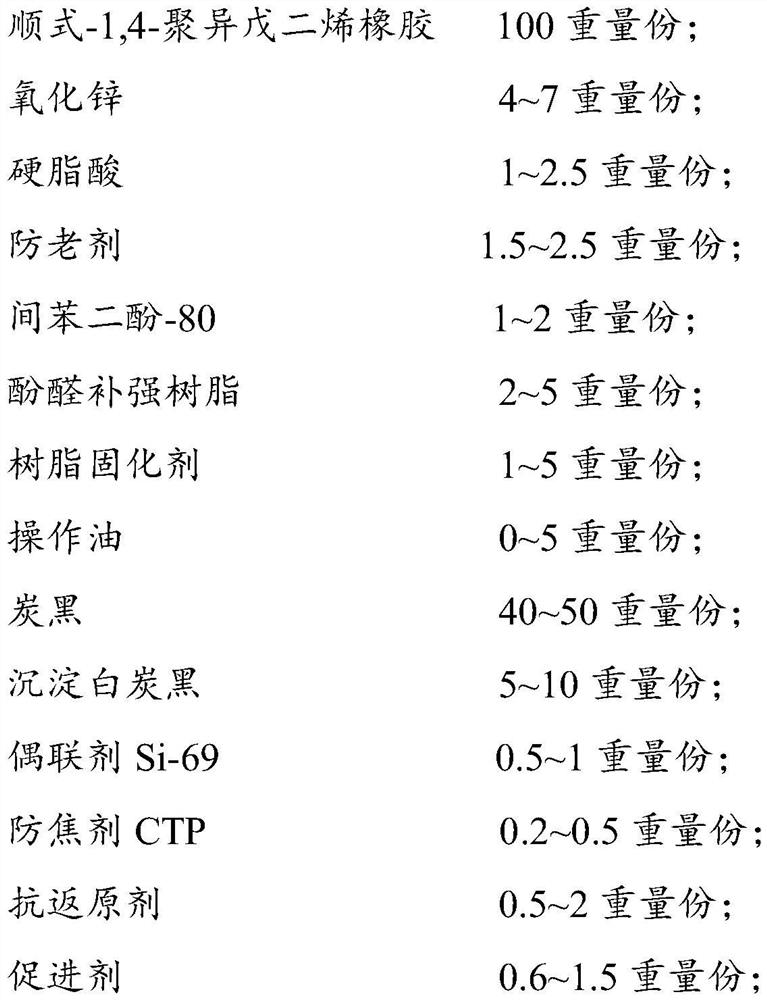

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of reinforcing layer rubber of the present invention, step is as follows:

[0039] Step 1, taking each component by proportioning;

[0040] Step 2: first put cis-1,4-polyisoprene rubber into the internal mixer for internal mixing, then add zinc oxide, stearic acid, anti-aging agent, resorcinol-80 and phenolic reinforcing resin for internal mixing, Then add carbon black, precipitated white carbon black and coupling agent Si-69 for banburying, and finally add operating oil for banburying, after banburying evenly, discharge the rubber and discharge the film to obtain the banburying film;

[0041] Step 3. Put the banbury film obtained in Step 2 on the open mill and add insoluble sulfur, accelerant, resin curing agent, anti-scorch agent CTP and anti-reversion agent during the open mill. The mixed film is obtained, that is, the reinforcing layer rubber.

[0042] In the above technical scheme, the initial temperature of the internal mixer is lower than...

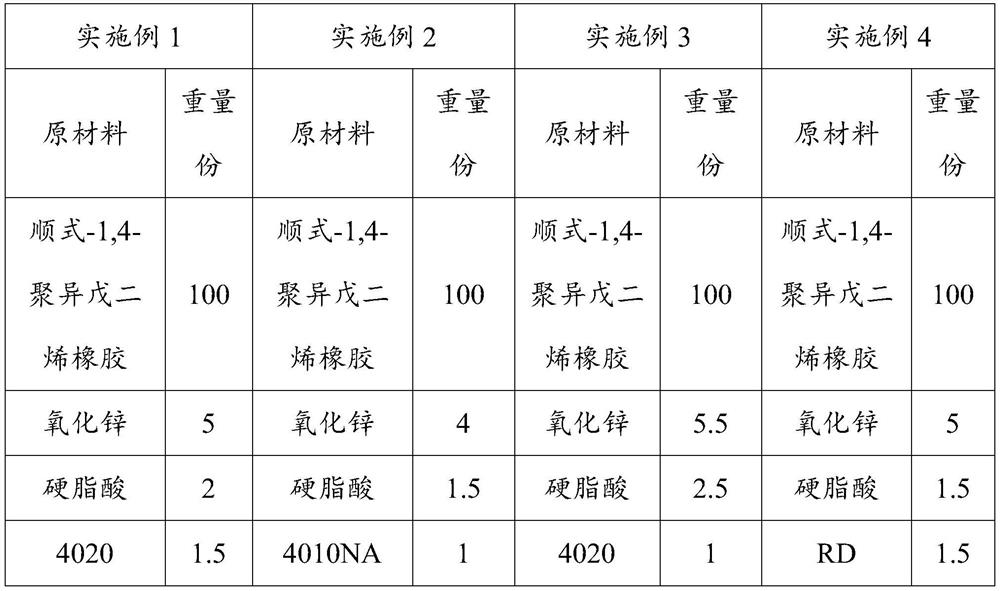

Embodiment 1~4

[0049] The formulations of the reinforcing layer rubbers in Examples 1-4 are shown in Table 1. Prepare as follows:

[0050] Step 1, taking each component by proportioning;

[0051] Step 2: first put cis-1,4-polyisoprene rubber into the internal mixer for internal mixing, then add zinc oxide, stearic acid, anti-aging agent, resorcinol-80 and phenolic reinforcing resin for internal mixing, Then add carbon black and precipitated white carbon black for banburying, and finally add operating oil for banburying. After banburying evenly, the rubber is discharged to get the banburying film; the initial temperature of the internal mixer is lower than 70°C, and the degumming temperature does not exceed 155°C, banburying time is 4-10min;

[0052] Step 3: Put the banbury film obtained in Step 2 on the open mill with a roll temperature of 40-80°C, and add insoluble sulfur, accelerator, resin curing agent, coupling agent Si-69, and anti-scorch agent CTP during the milling process and anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com