Multi-element mixed work medium condensating, separating, throttling and oleep cooling circular refrigeration system

A multi-component mixed working medium, condensate separation technology, applied in refrigerators, refrigeration and liquefaction, compressors with cascade work, etc., can solve problems such as low separation efficiency, inability to separate liquids, and insufficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

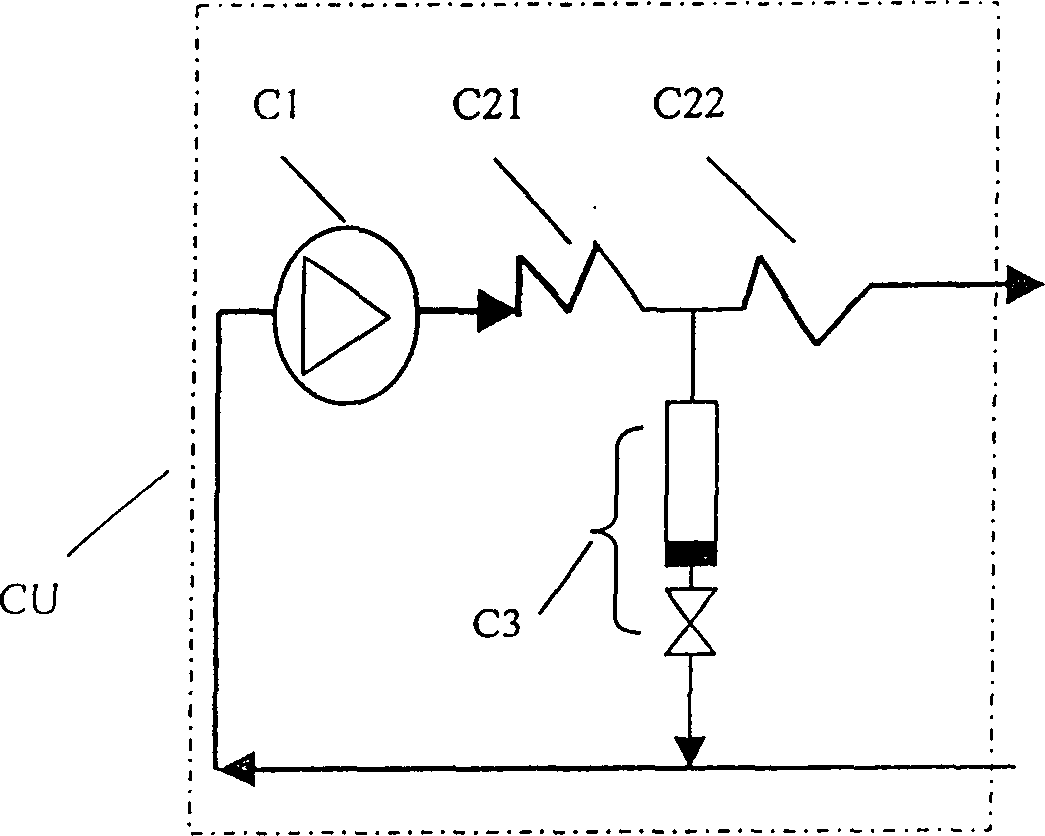

[0047] Embodiment 1: A single-stage oil-lubricated air-conditioning compressor is used to drive the refrigerating machine of the present invention to reach a temperature zone of 183K, and its structure diagram is shown in Image 6 . The specific structure of the compressor module is: the compressor C1 adopts a 1kW single-stage oil-lubricated air-conditioning compressor, the two pre-coolers C21 and C22 are conventional condensers, and the lubricating oil filter separator C3 is a conventional product. The connection method is as follows: The high-pressure outlet pipe of compressor C1 is connected to the inlet pipe of the first front cooler C21, and the outlet of C21 is connected with the inlet of the second front cooler C22 and the inlet of lubricating oil filter oil return device C3 through a three-way connecting pipe fitting, and is connected by the inlet of C22 The outlet constitutes the high-pressure outlet of the compressor module. The C3 outlet of the lubricating oil filte...

Embodiment 2

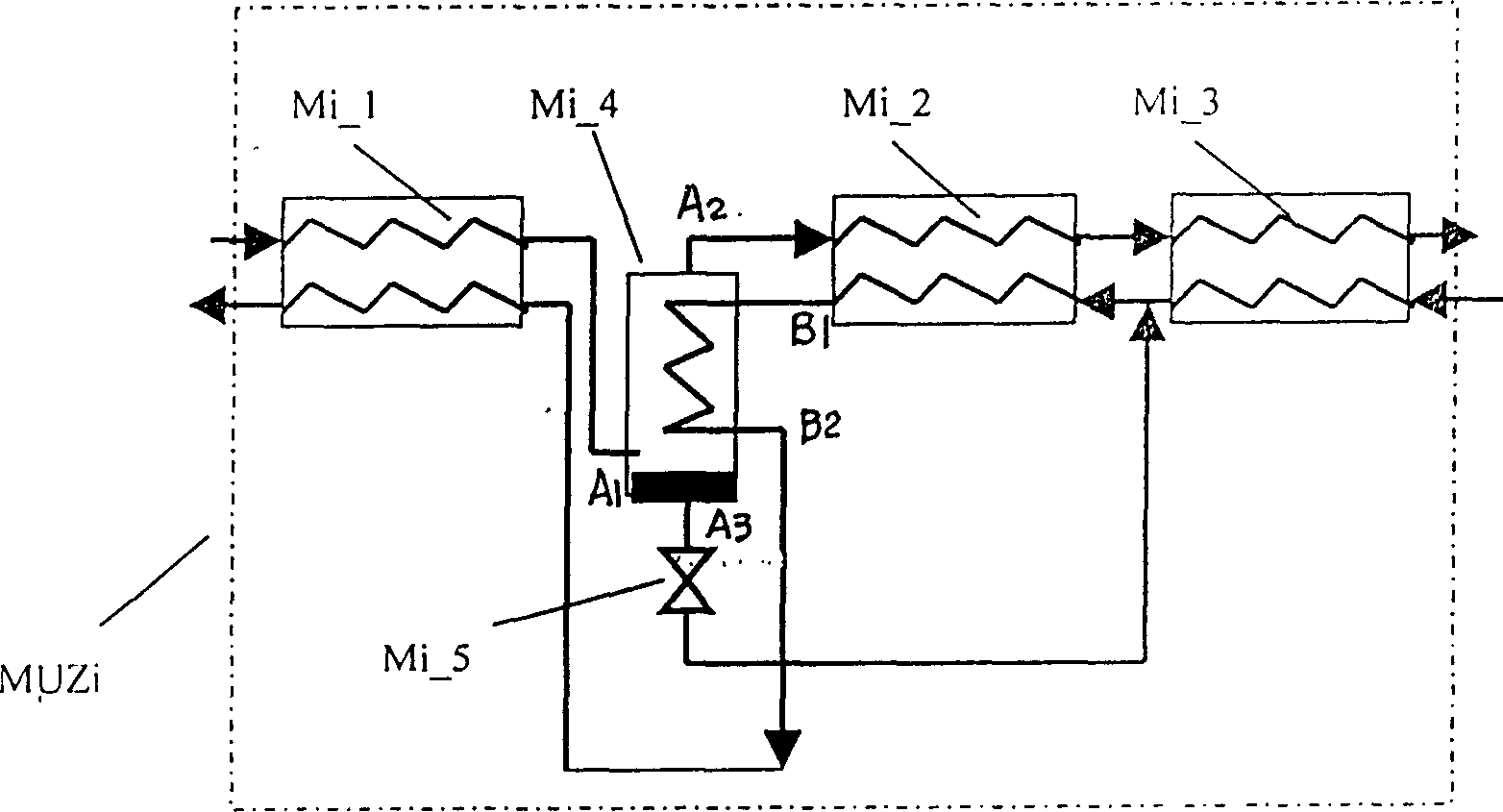

[0048] Embodiment 2: adopt the present invention to reach 120K temperature zone, its structural diagram sees Figure 7 . The structure of the compressor module is the same as in Embodiment 1. The intermediate refrigeration module MU adopts a three-stage mixed working medium refrigeration sub-module, in which the first-stage refrigeration sub-module MUZ1 includes a condensate separator M1_4, a throttling element M1_5 and its pipelines. The connection method is: the high-pressure outlet of the compressor module is connected to the The high-pressure inlet A1 of the condensing separator M1_4, the high-pressure liquid outlet A3 at the bottom of the condensing separator M1_4 are connected to the throttling element M1_5, the outlet of M1_5 is connected to the low-pressure inlet B1 of the condensing separator M1_4, the high-pressure gas outlet A2 of M1_4 is connected to the next-stage refrigeration module MUZ2 The high-pressure inlet is connected, and the low-pressure outlet B2 of th...

Embodiment 3

[0049] Embodiment 3: adopt the present invention to reach the liquid nitrogen temperature zone, see its structure Figure 8. The compressor module is the same as in Embodiment 1. The intermediate refrigeration module is composed of five-stage sub-modules, in which the first-stage mixed working medium refrigeration sub-module MUZ1 includes a decondensation separator M1_4, a throttling element M1_5, a pre-counterflow heat exchanger M1_1, and an intermediate counterflow heat exchanger M1_2. The method is: the high-pressure outlet of the compressor module is connected to the high-pressure inlet of the counterflow heat exchanger M1_1, the high-pressure outlet of M1_1 is connected to the high-pressure inlet of M1_4, the high-pressure gas outlet of M1_4 is connected to the high-pressure inlet of M1_2, and the high-pressure outlet of M1_2 is connected to the high-pressure The inlet is connected; the high-pressure separation liquid outlet of M1_4 is connected with the throttling eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com