Treatment method of desalted water generated in MDA preparation process

A treatment method and technology of preparation process, applied in the field of brine drainage, can solve the problems of pale green brine, can not be removed cleanly, affect drainage and reuse, etc., and achieve the effects of reducing environmental pressure, stable operation and strong pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

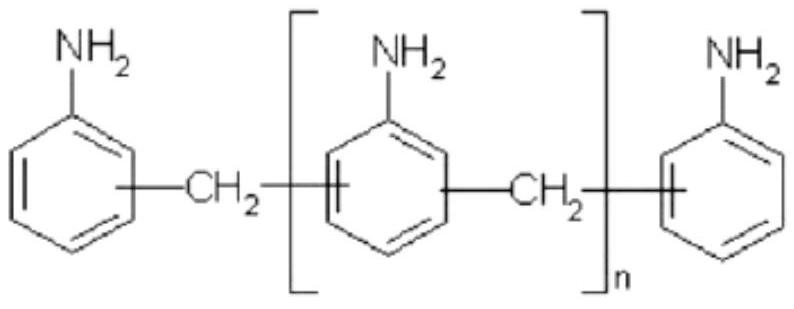

Image

Examples

preparation example Construction

[0035] The source of raw material used in the preparation example of the present invention, embodiment and comparative example is as follows:

[0036] Aniline: Wanhua self-produced aniline with a purity of 99.9%, reaching the industrial grade specified in GB2961-2014;

[0037] Hydrochloric acid: Wanhua self-produced hydrochloric acid with a concentration of 34%;

[0038] Unless otherwise specified, other raw materials are commercially available products.

[0039] The detection method and the instrument used in the preparation example of the present invention, the embodiment and the comparative example are as follows:

[0040] TOC measurement: Germany Jena 2100S TOC instrument, TOC / TN dual detector; the sample was adjusted to pH=2 with hydrochloric acid, and the sample was injected for analysis, and TOC was quantified with an external standard of sodium phthalate.

[0041] Bromophenol detection in brine (sum of the total content of monobromodichlorophenol, dibromomonochloroph...

preparation example M

[0047] The preparation of preparation example MDA

[0048] React hydrochloric acid (calculated as HCl) with a molar ratio of 0.3:1 and aniline to form aniline salt, and then add formaldehyde to undergo condensation reaction and transposition reaction. The molar ratio of formaldehyde to aniline is 0.35:1, and the reaction temperature is 50°C After the reaction is finished, a reaction mixture comprising diamine salts and polyamine salts of diaminodiphenyl is obtained. Adopt excessive 50%NaOH (the mol ratio of NaOH and hydrochloric acid is 1.10:1) to neutralize the reaction mixture, and the mixture after neutralization is sent into the stratifier to separate the organic phase and the water phase, and the organic phase passes through water (water and The volume ratio of the oil phase is 0.4:1) After washing once, water and aniline are preliminarily separated by 10kPa flash distillation, and then purified by 8barg steam distillation to obtain MDA.

Embodiment 1

[0050] MDA was prepared according to the preparation example, wherein the hydrogen bromide content in the raw hydrochloric acid was 84.8 mg / L.

[0051] Collect and combine the water phase and washing brine produced in the neutralization and washing process to obtain drain brine, add 34% hydrochloric acid to adjust the pH value to 5.1, and then use aniline as the extraction agent to extract (the phenol content in the aniline is 21.3mg / L) , the extraction temperature was 30°C, the mass ratio of aniline to brine was 0.2:1, and the content of MDA in the brine after extraction was 0.03mg / L, which achieved the purpose of extracting MDA. At the same time, it was detected that the content of phenol in the brine was 0.27 mg / L, the sodium bromide content is 3.74mg / L, and the aniline content is 3.9%. Next, the drained brine is subjected to 2barg steam stripping to remove aniline therein. Finally, sodium hypochlorite oxidant (the mass ratio of the amount added to the discharged brine is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com