Composite board surface gluing equipment for building material

A technology for composite boards and building materials, applied to wood processing equipment, adhesive application devices, manufacturing tools, etc., can solve the problems of cumbersome operation process and low gluing efficiency, and achieve the effects of improving work efficiency, saving glue, and leveling the glue level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

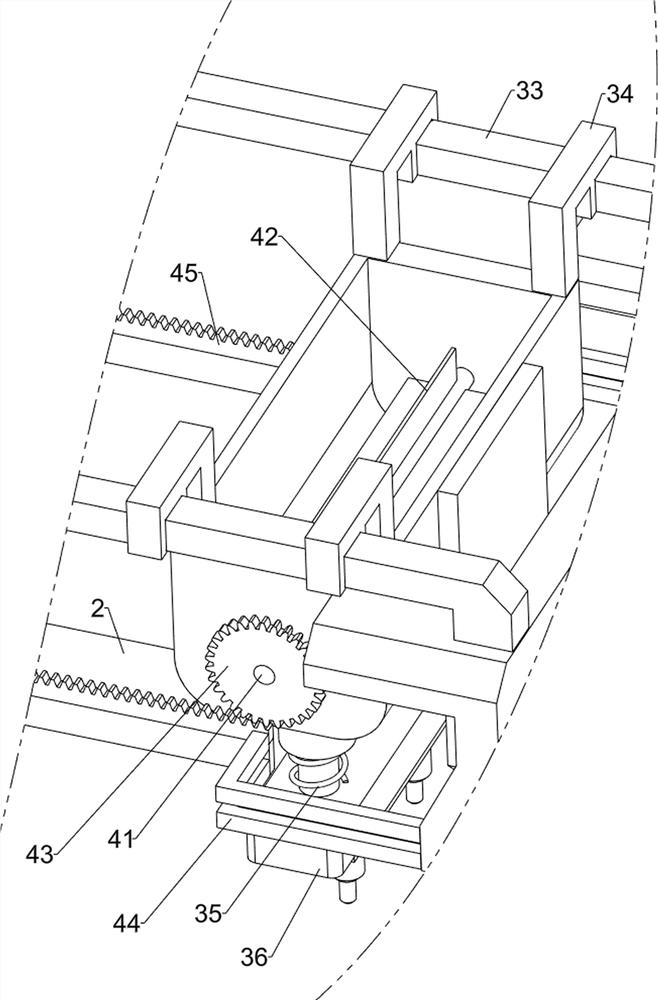

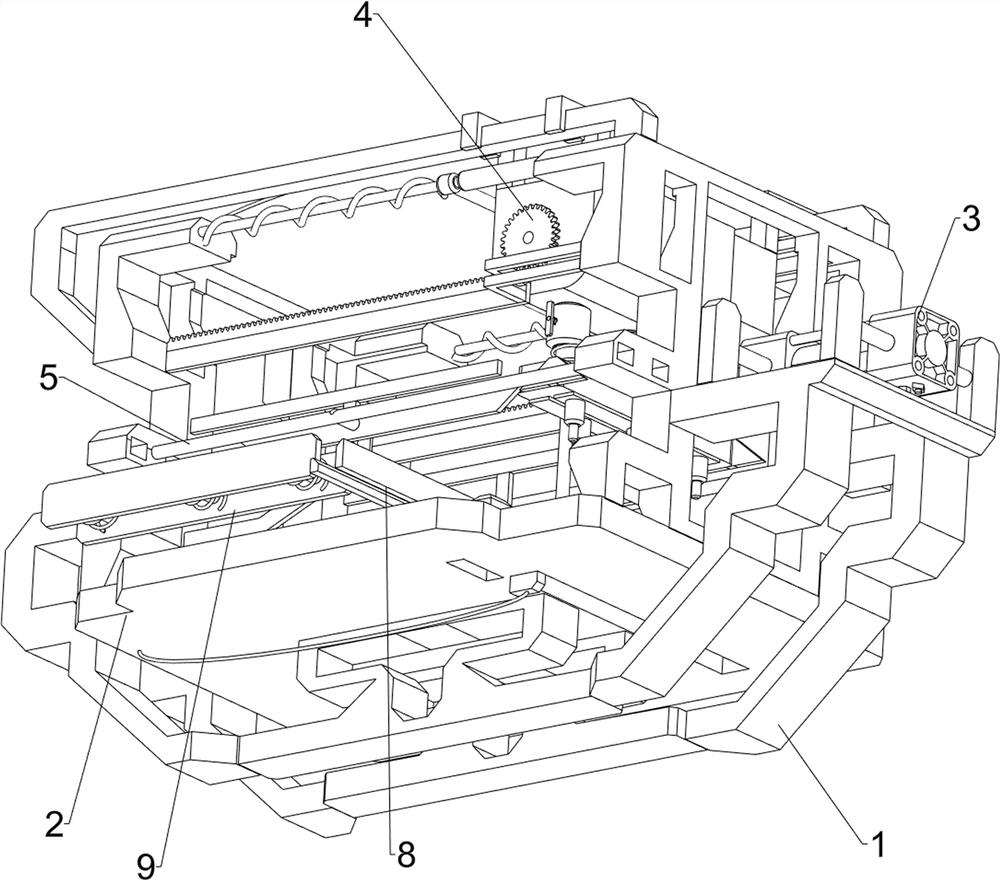

[0035] A kind of equipment for gluing on the surface of composite boards for building materials, such as Figure 1-6 As shown, it includes a base 1, a placement platform 2, a mobile unloading mechanism 3 and a stirring mechanism 4. The lower part of the base 1 is horizontally connected with a placement platform 2, and the base 1 is equipped with a mobile unloading mechanism 3. Stirring mechanism 4 is installed.

[0036] When it is necessary to glue the composite board, people put the composite board on the placement table 2, then pour the glue into the mobile blanking mechanism 3, and then control the mobile blanking mechanism 3 to work, glue the plywood, and move the The feeding mechanism 3 drives the stirring mechanism 4 to work, and the stirring mechanism 4 stirs the glue in the moving blanking mechanism 3 to prevent the glue from settling. After gluing is completed, people close the mobile unloading mechanism 3, then take off the composite board completed by gluing, then ...

Embodiment 2

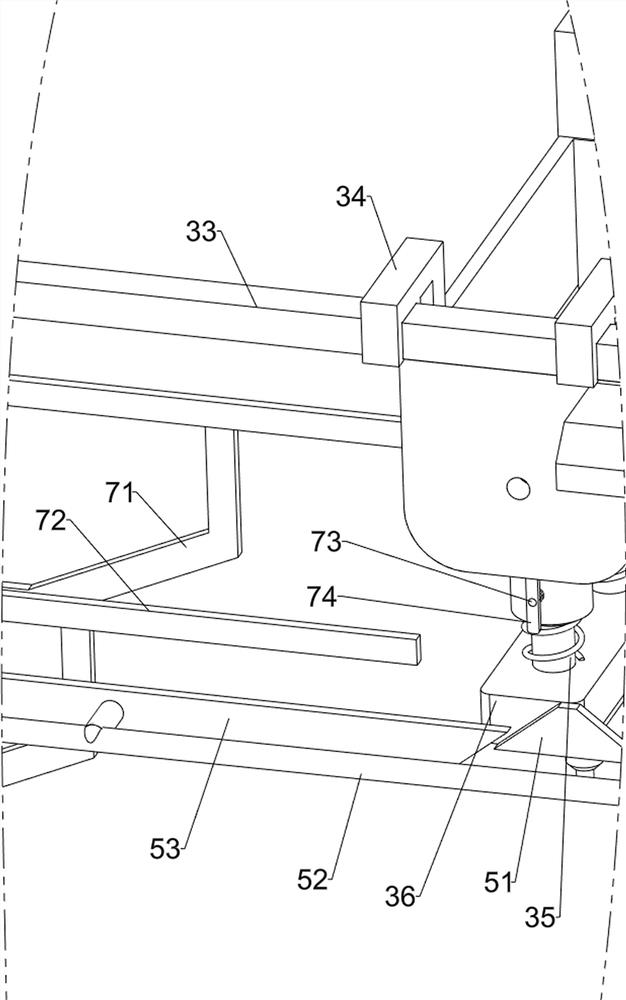

[0042] On the basis of Example 1, such as Figure 6-11 As shown, it also includes a pressing mechanism 5. The pressing mechanism 5 includes a first wedge block 51, a first fixed rod 52 and a second wedge block 53. The front and rear sides of the blanking assembly 36 are connected with the first wedge block 51. The front and rear sides of the base 1 are connected with first fixing rods 52 , and the inner sides of the first fixing rods 52 are connected with second wedge-shaped blocks 53 .

[0043] When the blanking assembly 36 moves to the right, the blanking assembly 36 drives the first wedge block 51 to move to the right, the second wedge block 53 pushes the first wedge block 51 to move downward, and the first wedge block 51 drives the blanking assembly 36 downward Move, shorten the distance between the blanking assembly 36 and the composite plate, avoid the glue falling on the composite plate from splashing, the elastic feed pipe 35 is stretched, when the first wedge 51 is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com