Double-piston indexing milling head

A dual-piston, indexing technology, used in milling machine equipment, details of milling machine equipment, large fixed members, etc., can solve the instability of pre-eccentric load guidance, affect the stability of spindle rotational drive, indexing chainring and indexing chainring The clamping and fixing are not stable enough to avoid the spindle jam, improve the eccentric load guide instability, and the spindle rotation and drive smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

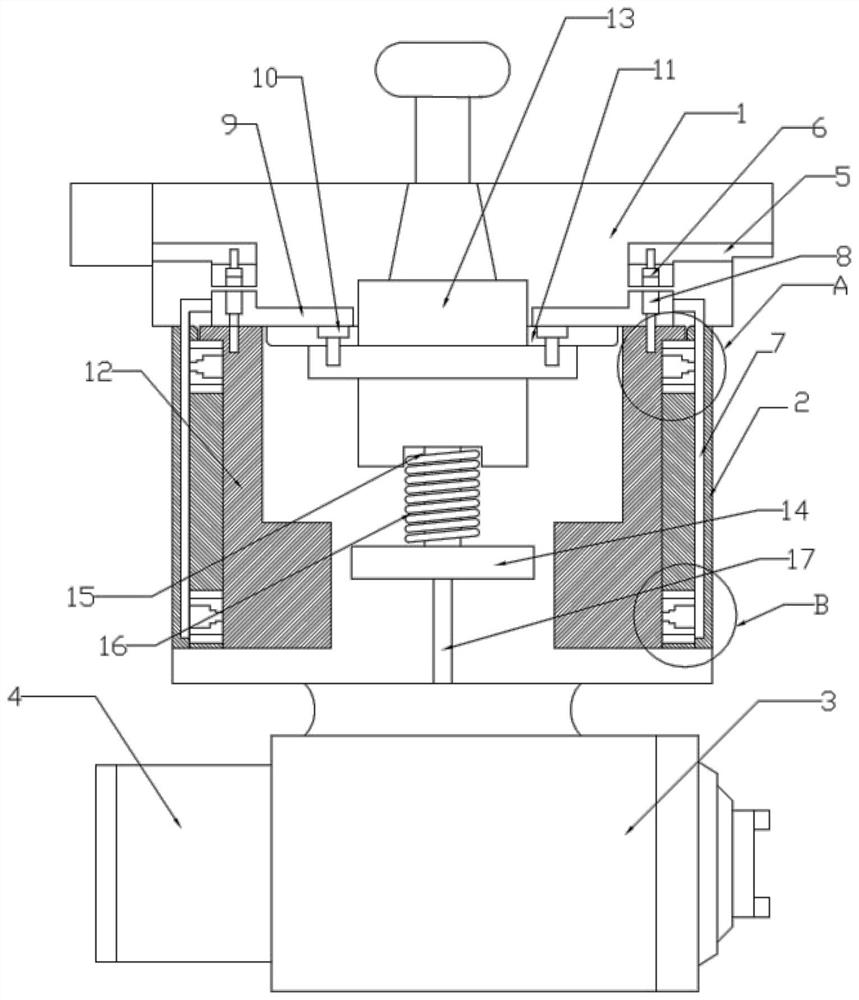

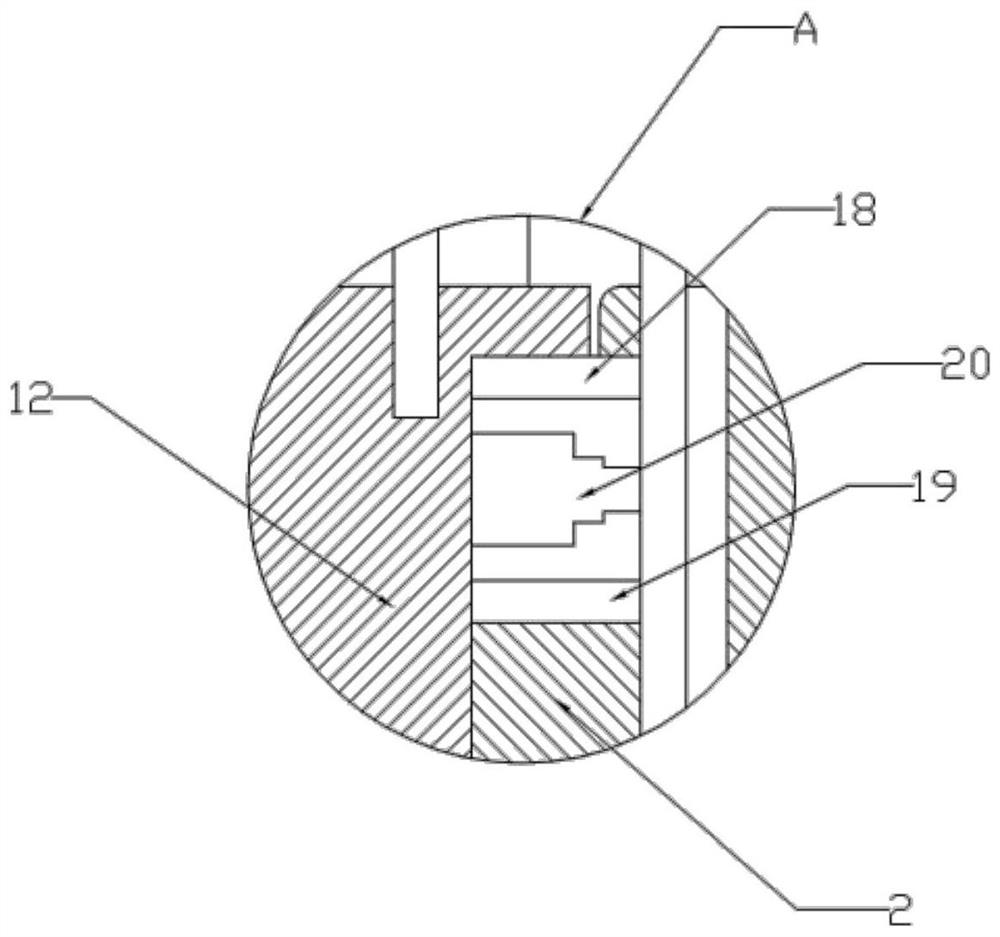

[0022] see Figure 1-4 , the present invention provides a technical solution: a double-piston indexing milling head, including a top seat 1, a fixed seat 2 and a spindle housing 3, the bottom of the top seat 1 is connected to the top of the fixed seat 2, and the top seat 1 Both the left and right sides of the inside are horizontally provided with a support frame 5, and the bottom of the support frame 5 is equipped with an indexing upper toothed plate 6, and the bottom of the left and right sides of the top seat 1 is provided with a movable seat 9, and the top of the movable seat 9 is An indexing lower toothed plate 8 matching the indexing upper toothed plate 6 is installed, and the meshing of the indexing upper toothed plate 6 and the indexing lower toothed plate 8 can make the eccentric load guidance of the indexing mechanism more stable. The fixed seat 2 In order from the inside to the outside, there are rotating rod 17, fixed column 15, spring 16, fixed block 13, tooth plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com