Sulfur-related equipment cleaning device with mixed heat source

A technology of cleaning device and heating device, which is applied in the direction of cleaning methods using liquids, cleaning hollow objects, cleaning methods and appliances, etc. It can solve the problems of high-temperature smoke that cannot be removed in time, incomplete atomization, and sparks, etc., and achieves a huge Commercial application value, obvious effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

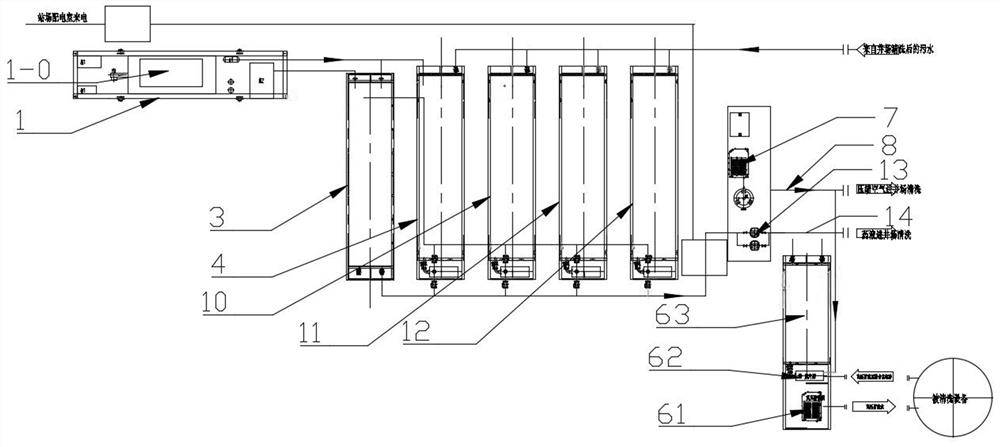

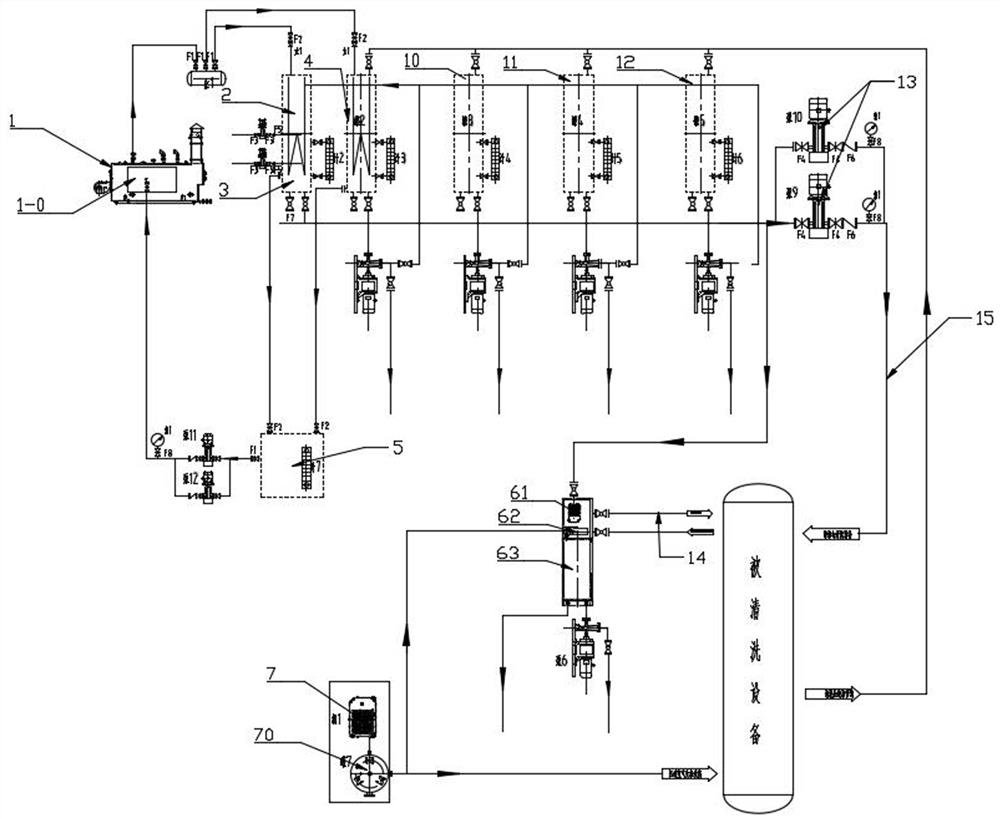

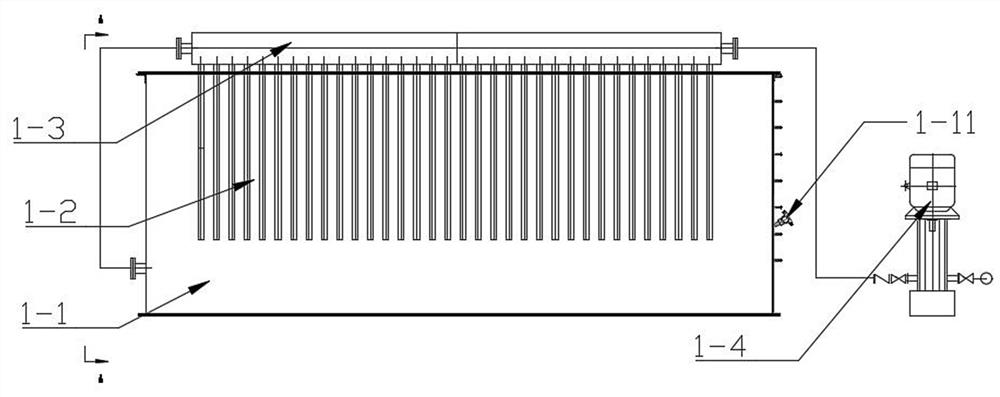

[0044] Such as figure 1 As shown, this implementation discloses a sulfur-related equipment cleaning device with a mixed heat source, including a power distribution system, a heating system, a heat exchange system, a cleaning system, a flushing system, a descaling system and a purging system, wherein the heating system includes The heating furnace skid 1 and the mixing heating device, the heat exchange system includes the hot water heat exchanger 2 and the chemical tank skid 3, the cleaning system includes the circulation booster device and the clean water tank skid 4, and the flushing system includes three parallel sewage tank skids, except The scale system is a jet sand removal and mud removal skid 6, including a high-pressure cleaner 61, a diaphragm pump 62, a water pump unit 13, a cleaning pipeline 14 and a sand removal tank 63, and the blowing system includes an air compressor 7, an air tank 70 and an air pipeline 8, such as image 3 , Figure 4 The hybrid heating device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com