Flotation Reagent Combination for Improving Recovery of Associated Cobalt in Fine-grained Copper Sulfide Ore

A technology for copper sulfide ore and flotation agent, applied in flotation, solid separation and other directions, can solve the problems of discharge of cobalt minerals, weak collection ability of cobalt minerals, low recovery rate of cobalt minerals, etc. The effect of increasing hydrophobicity and improving recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

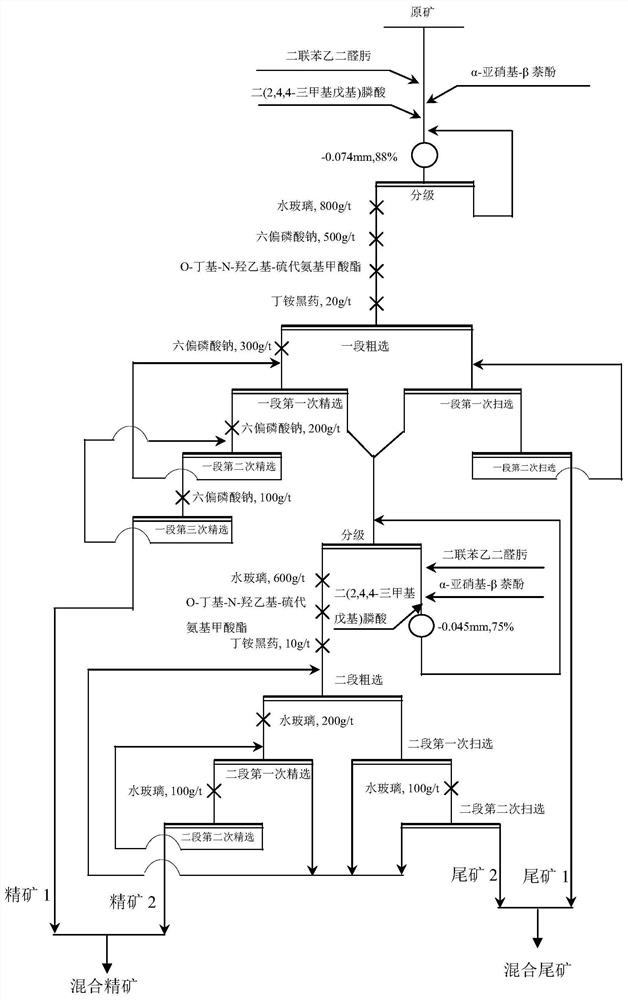

Method used

Image

Examples

Embodiment 1

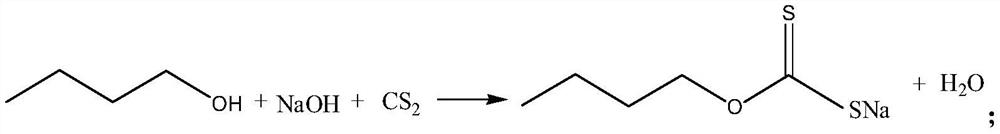

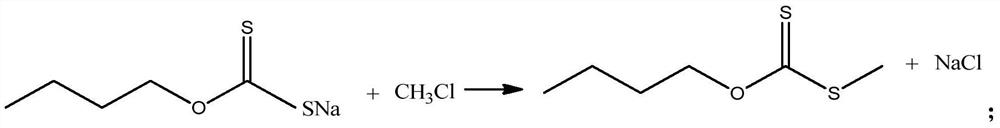

[0037] In parts by weight, the flotation agent combination includes: 90 parts of O-butyl-N-hydroxyethyl-thiocarbamate, 3 parts of biphenylglyoxaloxime, α-nitroso-β naphthol 5 parts, 2 parts of bis(2,4,4-trimethylpentyl)phosphonic acid.

Embodiment 2

[0039] In parts by weight, the flotation reagent combination includes: 91 parts of O-butyl-N-hydroxyethyl-thiocarbamate, 2 parts of biphenylglyoxalxime, α-nitroso-β naphthol 5 parts, 2 parts of bis(2,4,4-trimethylpentyl)phosphonic acid.

Embodiment 3

[0041] In parts by weight, the flotation agent combination includes: 90 parts of O-butyl-N-hydroxyethyl-thiocarbamate, 3 parts of biphenylglyoxaloxime, α-nitroso-β naphthol 4 parts, 3 parts of bis(2,4,4-trimethylpentyl)phosphonic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com