Crank arm sliding block plasma vibration ball mill

A plasma and vibrating ball technology, applied in grain processing and other fields, can solve the problems of low energy conversion efficiency, unfriendly environment, loud noise, etc., and achieve the effect of compact structure, environmental friendliness and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] Specific embodiments of the present invention will be described in detail below in conjunction with accompanying drawings:

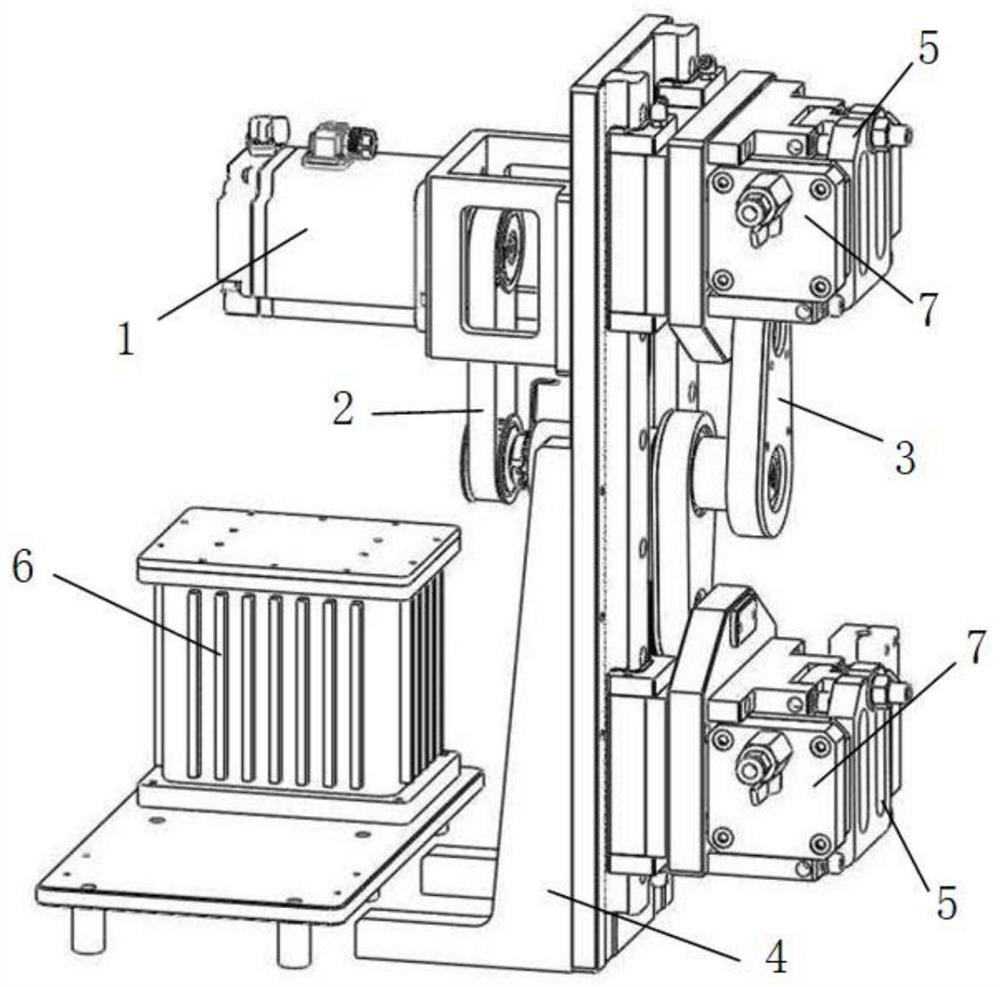

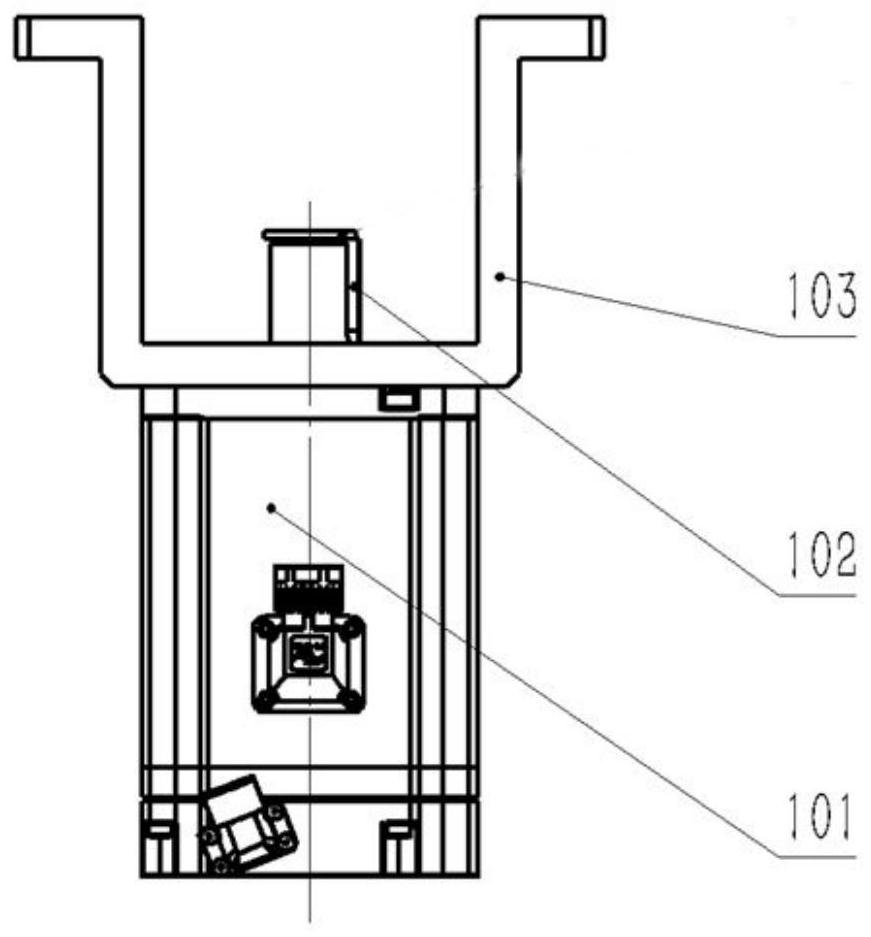

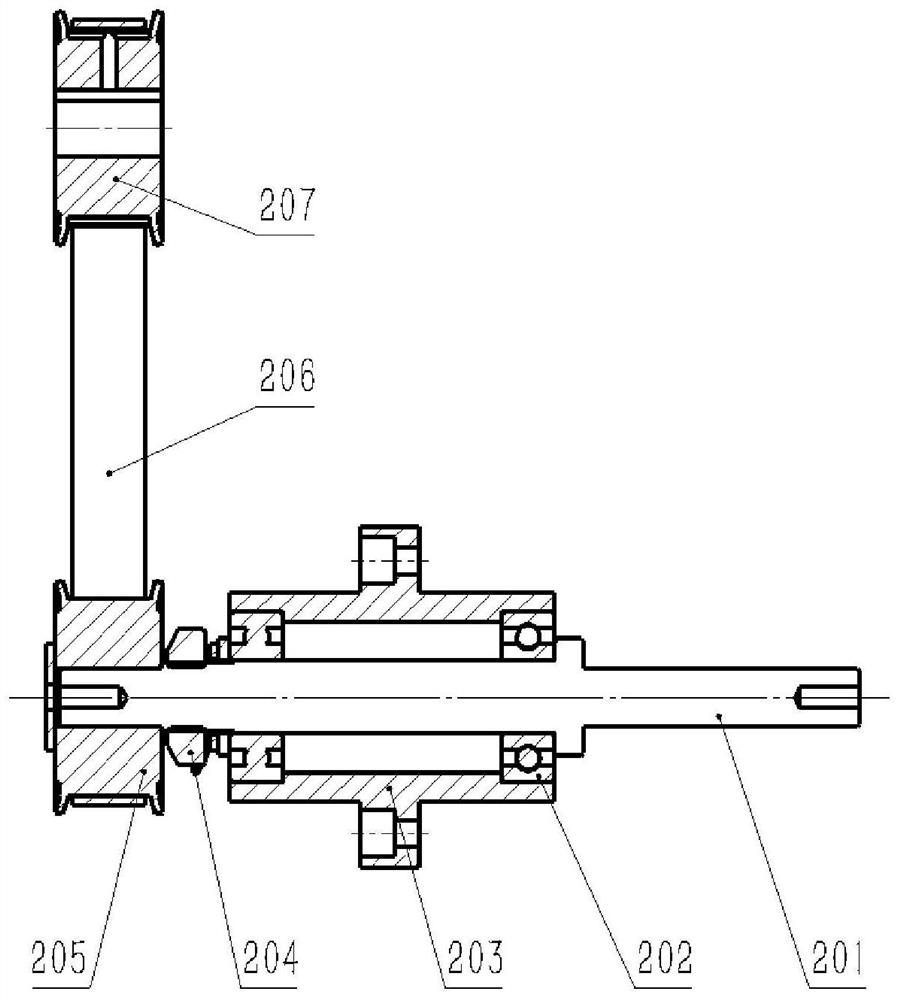

[0097] Such as figure 1 As shown, a curved arm slider plasma vibration ball mill includes a base mechanism 4, a power mechanism 1 arranged on the base mechanism, a transmission mechanism 2 installed on the base mechanism 4 and connected to the power mechanism, and installed on the base mechanism. The ball milling pot clamping mechanism 5 on the seat mechanism 4, the curved arm slider mechanism 3 connected with the transmission mechanism 2, the ball milling pot assembly 7 installed on the ball milling pot clamping mechanism 5, and the same plane as the base mechanism 4 Plasma high voltage discharge system6. The power mechanism transmits power to the crank arm movable block mechanism through the transmission mechanism, and drives the ball mill jar clamping mechanism and the ball mill jar assembly to move up and down through the crank arm slider str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com