Preparation method and application of Pt nanoparticle-loaded biochar catalyst

A nanoparticle, biochar technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve the effect of simple operation, low price, and reduction of the use of fossil resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Biomass pretreatment

[0035] The rice husks from Heilongjiang Province, China are washed and dried, and the rice husks are crushed with a grinder.

[0036] (2) Preparation of biochar

[0037] Put into the pyrolysis reactor, the volume of the reactor is 0.8L. Then it was raised from room temperature to 100°C at a rate of 7°C / min and kept for 6-8min. Then the temperature was raised to 550°C at a speed of 37°C / min, and the carbonization was continued for 30 minutes, and the obtained biochar was pulverized, and then the biochar with a particle size of less than 0.3 mm was screened out through a vibrating sieve machine.

[0038] (3) Loading of Pt nanoparticles

[0039] 0.1g of H 2 PtCI 6 ·6H 2 O was dissolved in 80 mL of deionized water, then 0.5 g of biochar was added, impregnated, and then stirred at 70 °C until the deionized water was evaporated to dryness;

[0040] The resulting product was washed 3 times with ethanol, dried in an oven at 60°C for 12 hours, t...

Embodiment 2

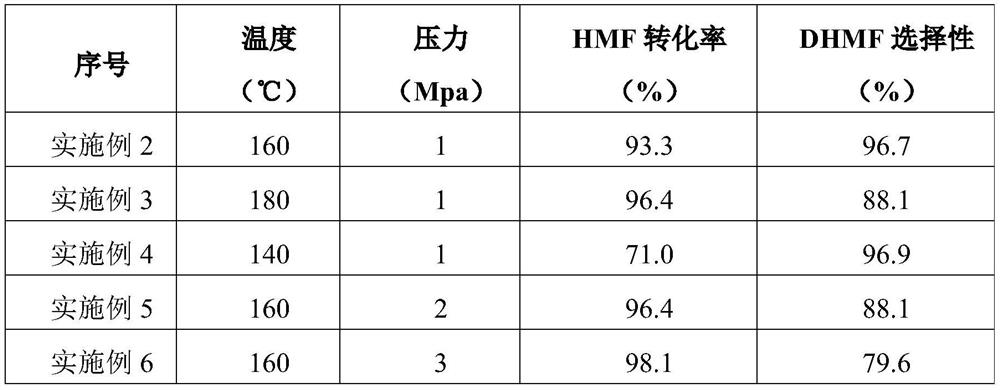

[0044] The Pt / BC (Pt loading 2.6%) prepared in Example 1 was used as a catalyst for the hydrogenation of 5-hydroxymethylfurfural to prepare 2,5-dimethylolfuran.

[0045] Preparation conditions: hydrogen pressure 1-3MPa; temperature 140-180°C; reaction time 10h; n-butanol as solvent.

[0046] Concrete preparation steps are as follows:

[0047] (1) Add 0.5gHMF and 30mL n-butanol into a stainless steel reactor, then add 0.05gPt / BC catalyst;

[0048] (2) The reactor is filled with H 2 Pressurize to 1MPa, and open the valve to ventilate to decompress the reactor to atmospheric pressure, repeat this process 10 times, to ensure that 99.99% of the air in the reactor is covered by H 2 Instead, the reactor was then pressurized with 1 MPa of hydrogen, the temperature was raised to 160 °C, and stirred at a rate of 500 rpm to fully mix the reactants with the catalyst.

[0049] Product analysis: Analysis was performed according to an internal standard (n-tridecane) using a gas chromatogr...

Embodiment 3

[0051]In this example, the difference from Example 2 is that the reaction temperature is 180° C., and the rest of the content is the same as that of Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com