Preparation method of compound milk powder

A production method and composite technology, which are applied to dairy products, milking devices, other dairy products, etc., can solve the problems of unreasonable use of waste heat for heating effect, inconsistent heating degree, uneven heating of raw milk, etc., and achieve safe use. Convenience, efficiency, and quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

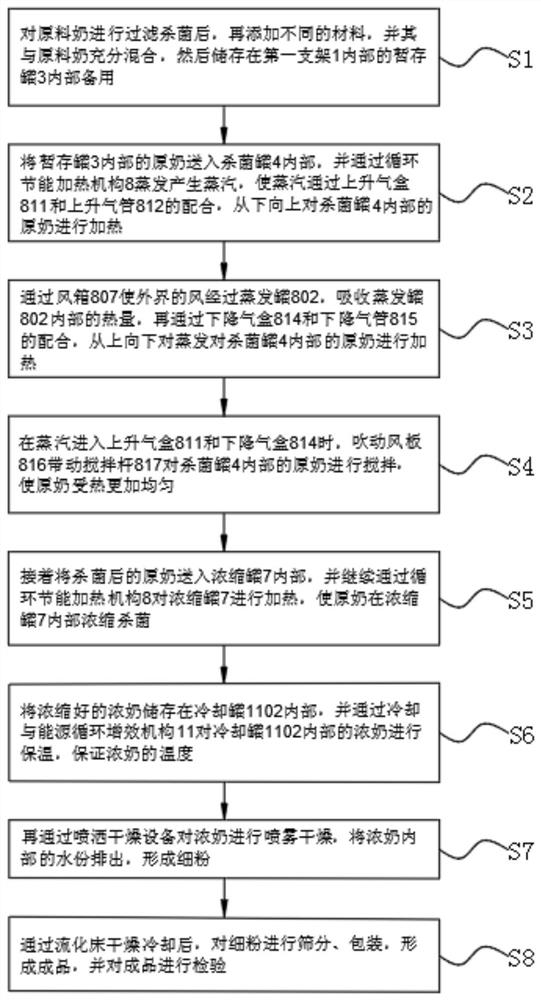

[0046] Example: such as figure 1 As shown, the present invention provides a kind of technical scheme, a kind of preparation method of composite milk powder, comprises the steps:

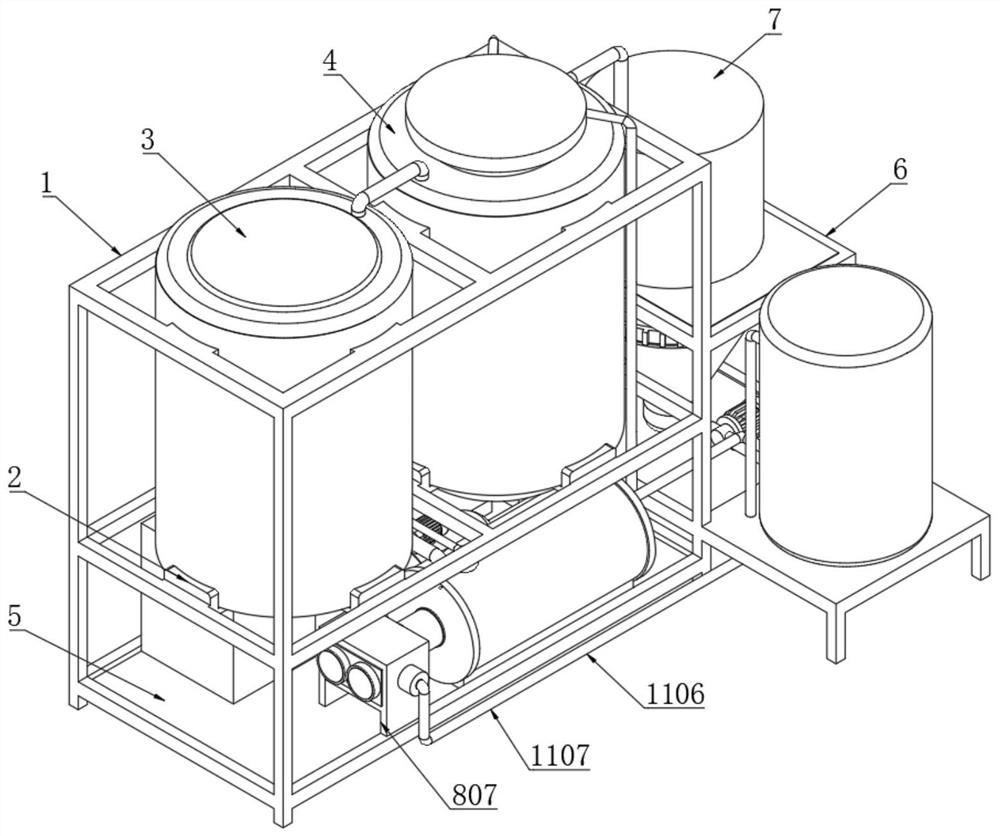

[0047] S1. After the raw milk is filtered and sterilized, different materials are added and fully mixed with the raw milk, and then stored in the temporary storage tank 3 inside the first bracket 1 for standby;

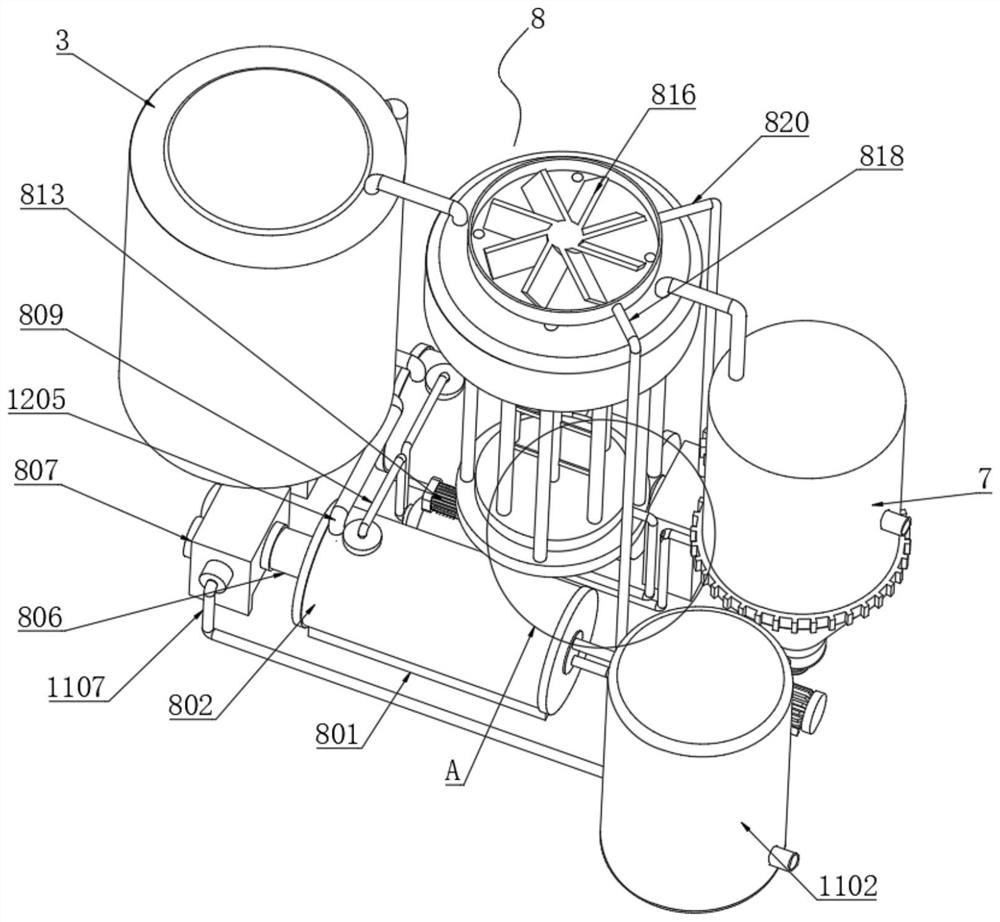

[0048] S2. Send the raw milk inside the temporary storage tank 3 into the inside of the sterilization tank 4, and evaporate through the circulation energy-saving heating mechanism 8 to generate steam, so that the steam passes through the cooperation of the rising air box 811 and the rising air pipe 812, and the sterilization tank 4 is heated from bottom to top. The raw milk inside is heated;

[0049] S3. Let the outside wind pass through the evaporation tank 802 through the bellows 807, absorb the heat inside the evaporation tank 802, and then through the cooperation of the descending air b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com