Vanadium redox flow stack assembly process

An assembly process and liquid flow technology, which is applied in the direction of circuits, manufacturing tools, fuel cells, etc., can solve the problems of unstable quality and low production efficiency of vanadium liquid flow stack assembly process, and achieve good connection stability and not easy to be damaged Erosion, guarantee the effect of normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

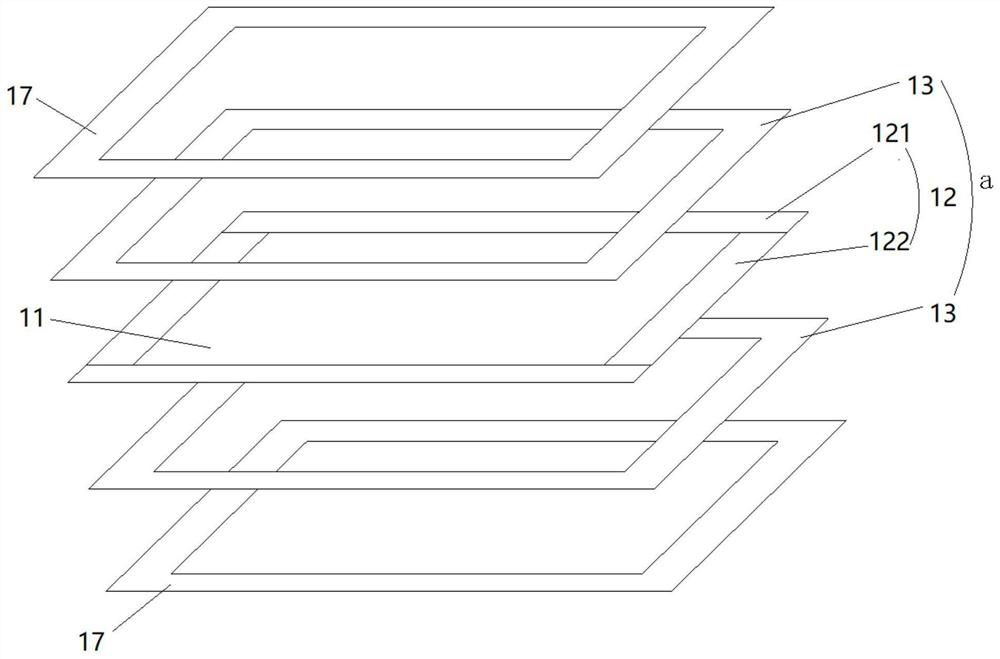

[0047] The structure of stack a is as Figure 20 shown.

[0048] The invention provides a vanadium liquid flow stack assembly process, comprising the following steps:

[0049] S1 assembles the cell stack unit 1.

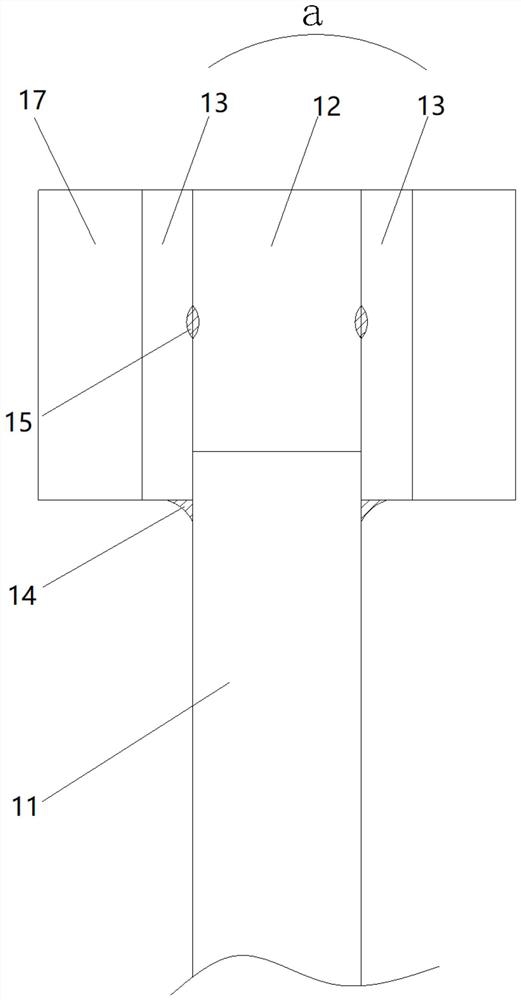

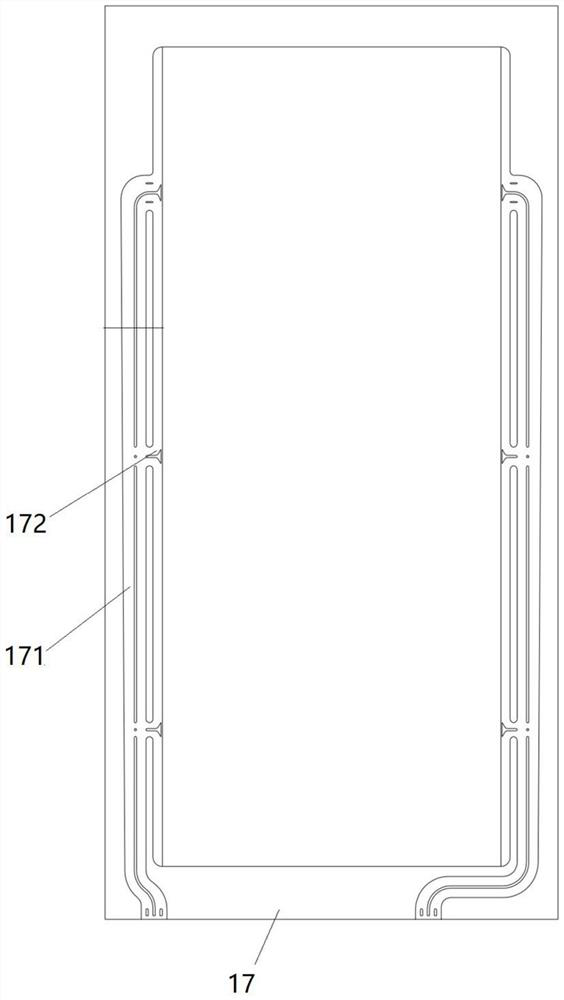

[0050] Such as Figure 1-5 As shown, the assembly steps of the battery unit mainly include:

[0051] A. Assembly of bipolar plate components:

[0052] A1, the insulating strip 1 121 and the insulating strip 2 122 are put together on the periphery of the entire edge area of the bipolar plate 11 to form the insulating frame 12, and the edge of the hollow area in the middle of the insulating frame 12 is close to the periphery of the bipolar plate 11, that is , insulating strip one 121 and insulating strip two 122 are close to the bipolar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com