Winter heat preservation device for high-pressure paint can

A heat preservation device and paint can technology, applied in the field of paint cans, can solve the problems of clogged pipe spray gun equipment, long time consumption, inconvenience, etc., to improve stability and safety, avoid excessive temperature, and ensure normal use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

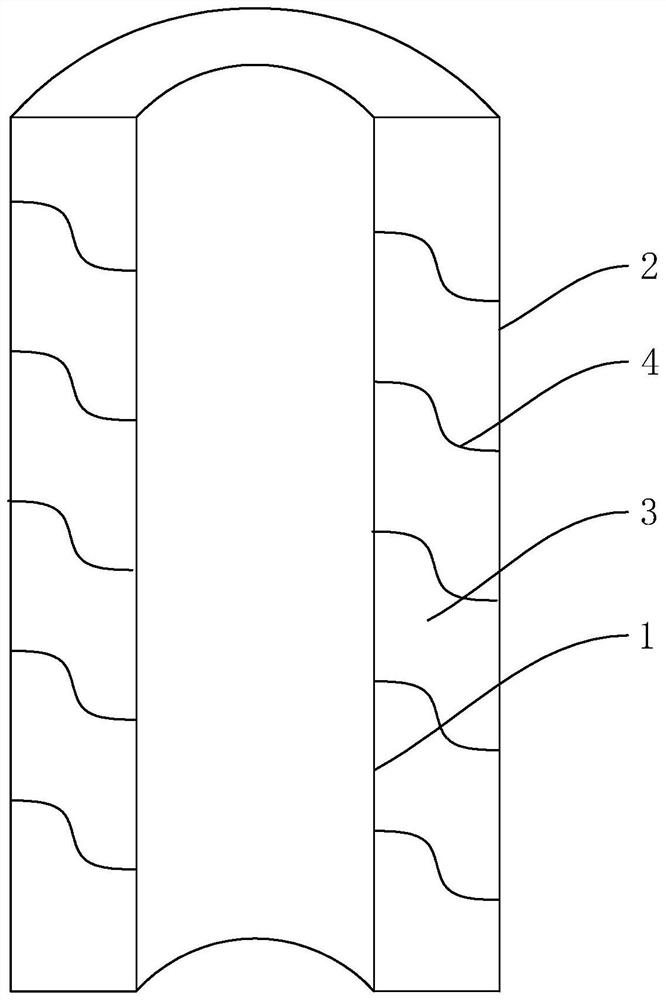

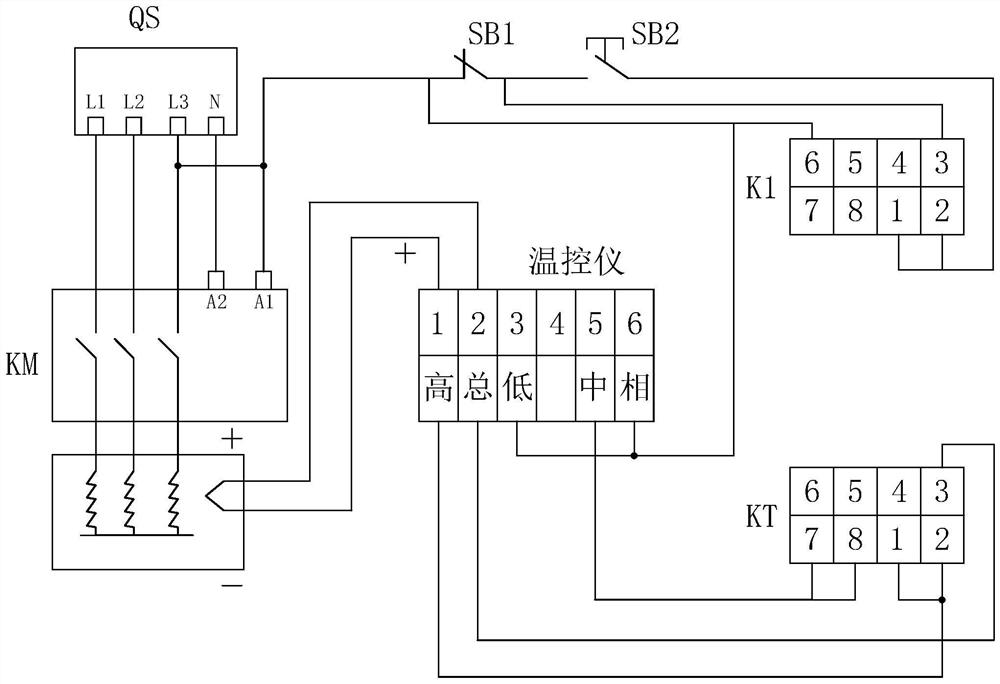

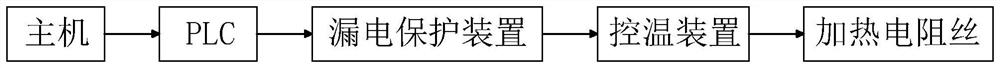

[0014] This embodiment provides a high-pressure paint tank winter heat preservation device, the structure is as follows: Figures 1 to 3 As shown, it includes a high-voltage insulating inner wall and a heat-insulating outer wall arranged at intervals from the inside to the outside. There is a gap between the high-voltage insulating inner wall and the heat-insulating outer wall. In the gap, there is a heating resistance wire wound outside the high-voltage insulating inner wall. The heating resistance wire is connected externally for A temperature control device for adjusting the temperature in the gap, the temperature control device includes an over-temperature alarm device for warning when the temperature is too high, and an electric leakage protection device.

[0015] The heating resistance wire is evenly wound outside the high-voltage insulating inner wall; the material of the high-voltage insulating inner wall is set to be stainless steel; the material of the thermal insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com