Preparation method of high-capacity nitrogen-doped carbon-coated SnOx quantum dot lithium ion battery negative electrode material

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, nanotechnology for materials and surface science, negative electrodes, etc., can solve the problems of active material falling off and affecting the electrochemical performance of materials, and achieve mild experimental conditions, The effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

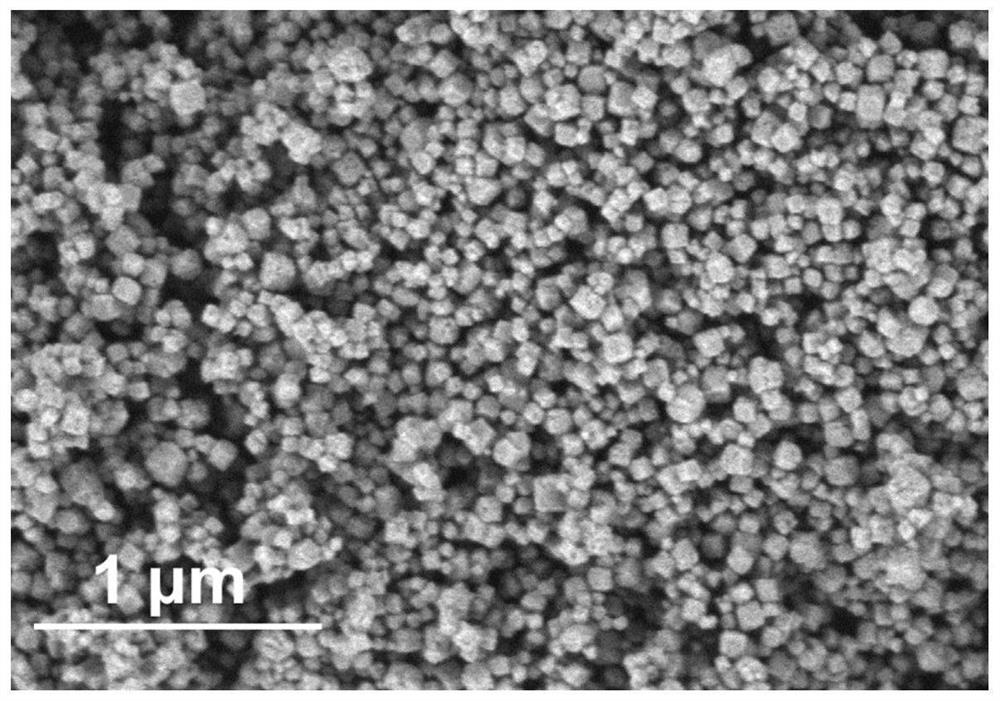

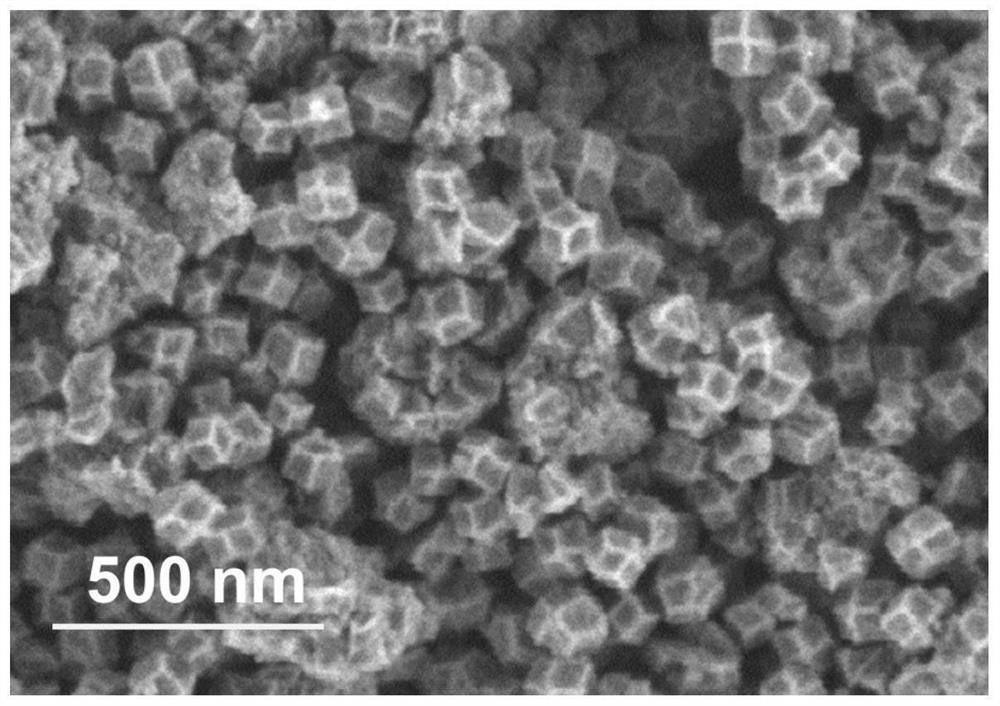

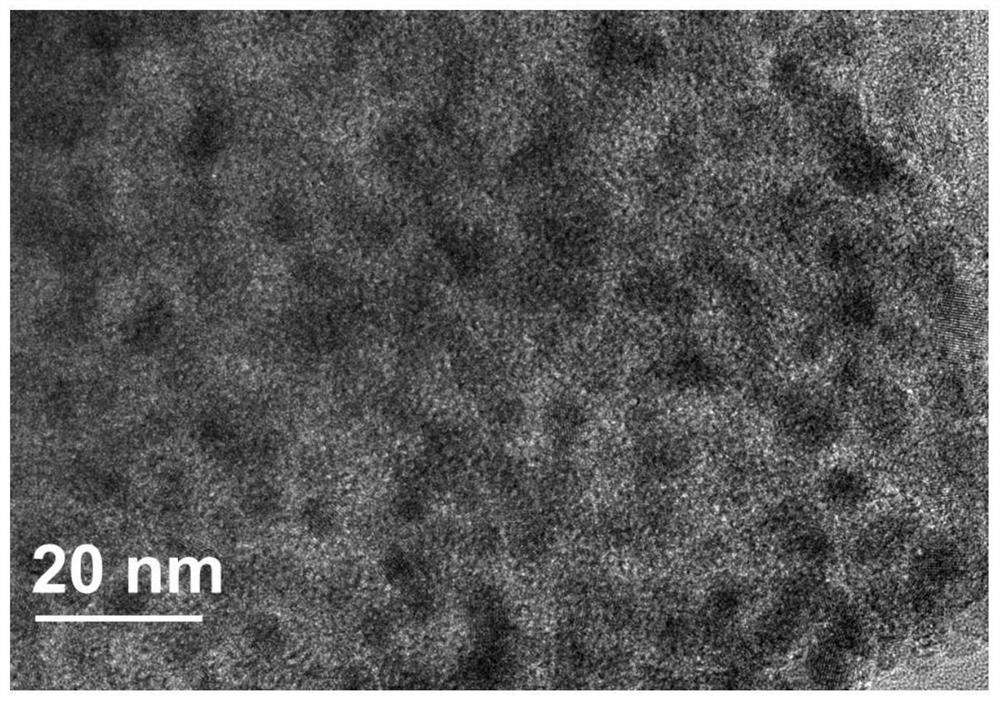

Image

Examples

Embodiment 1

[0040] Add 1mmol of crystalline tin tetrachloride and 8mmol of sodium hydroxide into 50mL of distilled water, stir until the reactants dissolve to form a clear and transparent solution, and control the temperature of the clear and transparent solution at about 10°C. 1 mmol of zinc sulfate heptahydrate was added to the above clarified solution, stirred for 5 hours to obtain a white suspension; after the reaction, centrifuged to obtain a white solid powder, which was washed with distilled water. The obtained product was dried overnight in a 50° C. forced-air drying oven to obtain a zinc stannate precursor.

[0041] Transfer all the products obtained in the previous step to polydiene dimethyl ammonium chloride aqueous solution, stir for 10-60 minutes, centrifuge to recover the powder after stirring and wash with deionized water; transfer the washed product directly to polystyrene In the aqueous solution of sodium sulfonate, stir for 10-60min, after stirring, centrifuge to recover...

Embodiment 2

[0052] The steps are the same as in Example 1, except that the molar ratio of the precursor and zinc nitrate is changed to 1:4, and other conditions remain unchanged, and finally carbon-coated SnO x Quantum dot composite (SC-4-800). Figure 7 It is the cycle performance diagram of SC-4-800 composite material. The discharge and charge specific capacities of the composite in the first cycle are 2948 and 1711 mAh g, respectively -1 , the reversible specific capacity reached 1824mAh g after 100 cycles -1 , the Coulombic efficiency is close to 100%.

Embodiment 3

[0054] The steps are the same as in Example 1, only the molar ratio of the precursor and zinc nitrate is changed to 1:6, and other conditions remain unchanged, and finally carbon-coated SnO x Cycle performance graph of quantum dot composite (SC-6-800). Figure 8 It is the cycle performance diagram of SC-6-800 composite material. The discharge and charge specific capacities of the composite in the first cycle are 2133 and 1480 mAh g, respectively -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com