Self-healing branched polyethylenediamine hydrogel microcapsule composite material, its preparation method and application

A technology of polyethylene diamine and composite materials, which is applied in the direction of secondary batteries, electrochemical generators, structural parts, etc., to achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

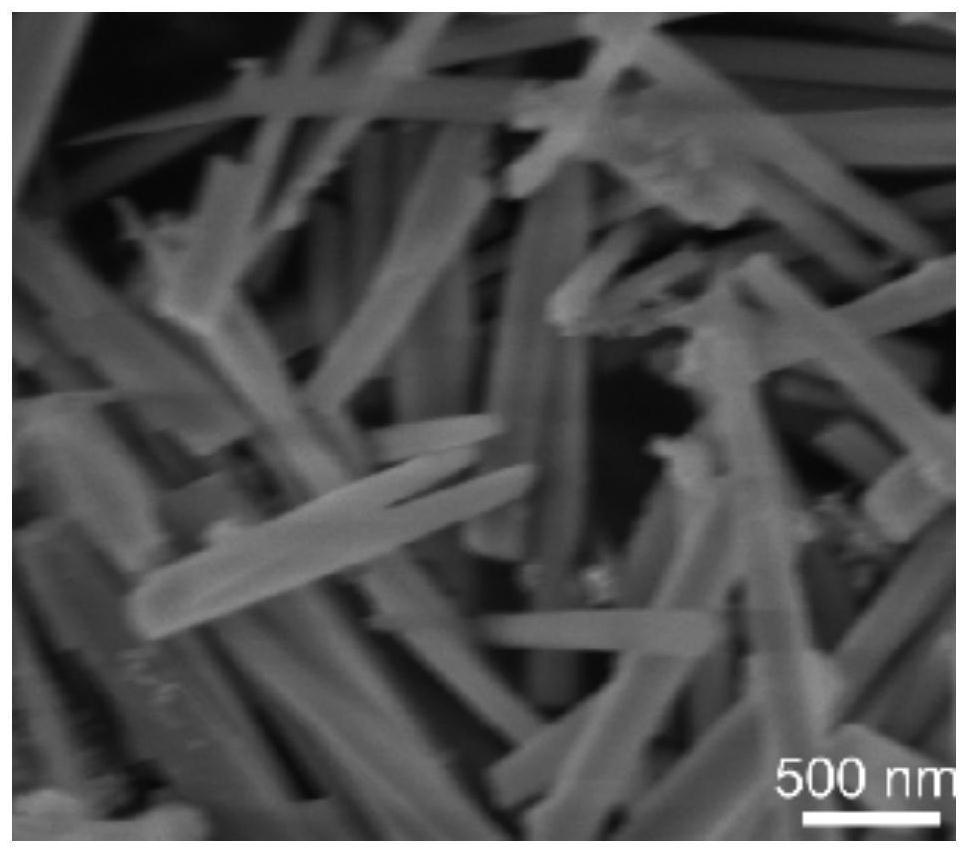

[0049] A preparation method of nano vanadium pentoxide self-healing microcapsule composite material, comprising the following steps:

[0050] 1) Dissolve 0.5 g of commercially available vanadium pentoxide in 20 mL of ethanol, stir and add an appropriate amount of hydrogen peroxide to adjust the pH to ≈1. After stirring evenly, the solution was transferred to a polytetrafluoroethylene liner and placed in an oven at 160°C for hydrothermal reaction. After the reaction, cool to room temperature, centrifuge and wash twice, dry in an oven at 50°C, and calcined to obtain the product nano-vanadium pentoxide;

[0051] 2) Dissolve 7.5 g of glucose in 30 mL of water, then transfer the solution to a polytetrafluoroethylene liner, conduct a hydrothermal reaction in an oven at 150 °C, cool to room temperature, and wash twice by centrifugation, then place the solution in an oven at 60 °C Medium dry. The dried samples were carbonized at 350 °C to obtain carbonaceous microspheres;

[0052] ...

Embodiment 2

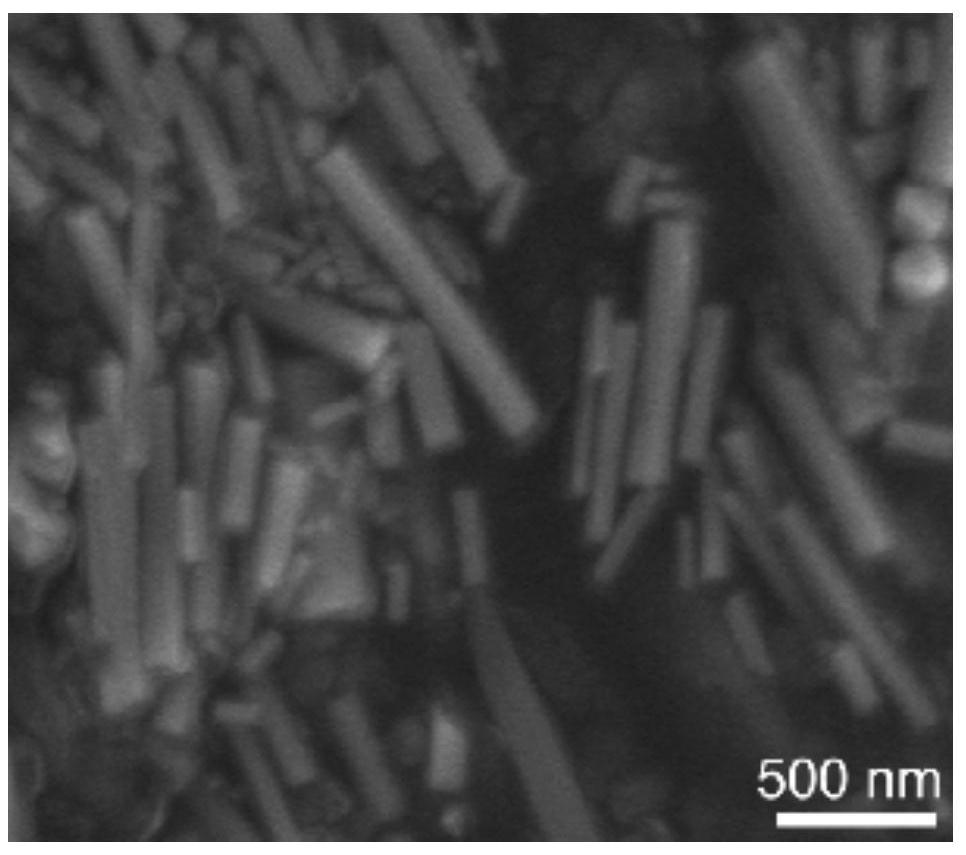

[0057] A preparation method of nano vanadium pentoxide self-healing microcapsule composite material, comprising the following steps:

[0058] 1) Dissolve 0.4 g of commercially available vanadium pentoxide in 25 mL of ethanol, stir and add an appropriate amount of hydrogen peroxide to adjust the pH to 1. After stirring evenly, the solution was transferred to a polytetrafluoroethylene liner and placed in an oven at 150°C for hydrothermal reaction. After the reaction, cool to room temperature, centrifuge and wash 3 times, dry in an oven at 55°C, and calcinate to obtain the product nano-vanadium pentoxide;

[0059] 2) Dissolve 8.8 g of glucose in 35 mL of water, transfer the solution to a polytetrafluoroethylene liner, conduct hydrothermal reaction in an oven at 150 °C, cool to room temperature, and centrifuge twice for washing. Dry in oven. The dried samples were carbonized at 350 °C to obtain carbonaceous microspheres;

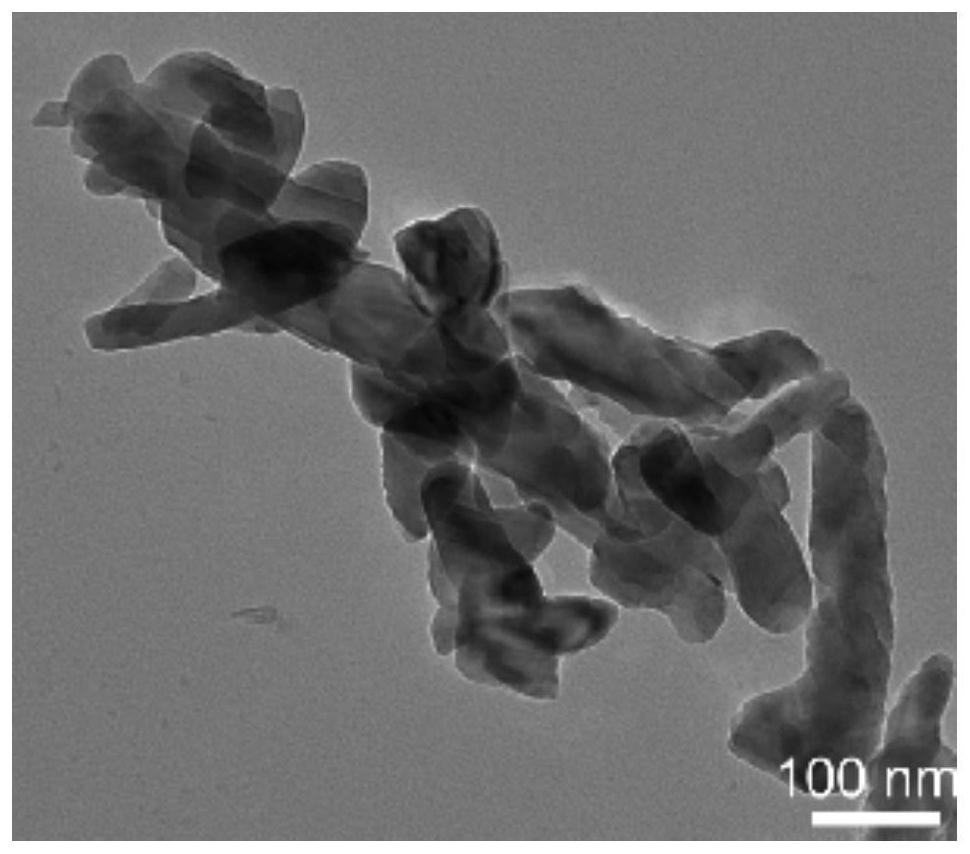

[0060] 3) Dissolve 0.5 g of branched polyethylene diami...

Embodiment 3

[0065] A preparation method of nano vanadium pentoxide self-healing microcapsule composite material, comprising the following steps:

[0066] 1) Dissolve 0.6 g of commercially available vanadium pentoxide in 35 mL of ethanol, stir and add an appropriate amount of hydrogen peroxide to adjust the pH ≈ 2. After stirring evenly, the solution was transferred to a polytetrafluoroethylene liner, and placed in an oven at 170°C for hydrothermal reaction. After the reaction, cool to room temperature, centrifuge and wash 5 times, dry in an oven at 70°C, and calcinate to obtain the product nano-vanadium pentoxide;

[0067] 2) Dissolve 8.5 g of glucose in 30 mL of water, transfer the solution to a polytetrafluoroethylene liner, conduct hydrothermal reaction in an oven at 150 °C, cool to room temperature, and centrifuge twice for washing. Dry in oven. The dried sample was carbonized at 500 °C to obtain carbonaceous microspheres;

[0068] 3) Dissolve 0.45 g of branched polyethylene diamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com