Cattle-pulling field raking machine

A technology of ox-pulled field raking machines and raking knives, applied to agricultural machinery and implements, applications, plows, etc., can solve the problems of slowness, backwardness of human power machinery, and no improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

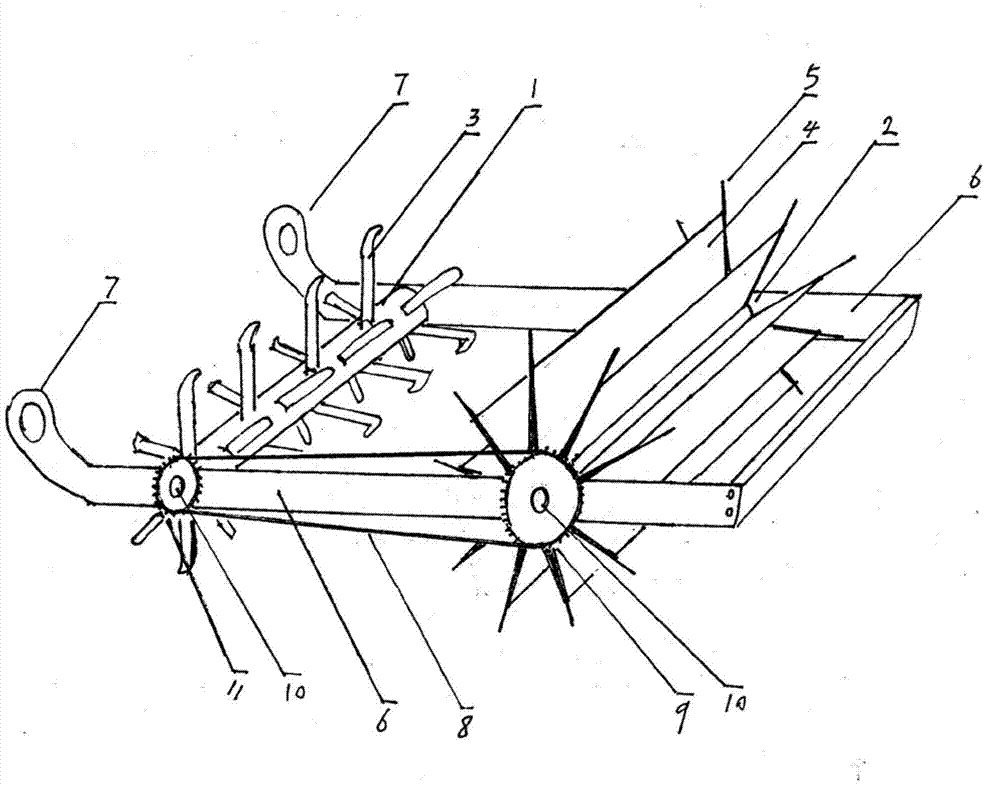

[0010] The cattle-drawn raking machine will be further explained below in conjunction with the anti-plot.

[0011] figure 1 It is a three-dimensional surface view of the oblique side of the cattle-drawn field raking machine. The ox-pulled field raking machine shown in this picture is not very complicated. The main structure is that two front and rear rollers are installed side by side in a fixed iron frame (6). This monster is not suitable for walking on flat ground, but It is suitable for walking in the bumpy paddy fields. On the front multi-cutter roller (1) of this cattle rake, there are many dislocated and evenly distributed rakes (3), and the tail of each rake (3) is bent, so that the multi-rake roller (1) rotates There are no gaps in the paddy fields that have been stirred, and the mud will be smashed into pieces. The leaves (4) on a multi-blade rotating roller (2) arranged side by side at the rear are also evenly distributed, with the rotating roller as the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com