Hot pressed reinforced wooden floor board and upper mold steel plate of hot press

A technology for strengthening wooden floors and steel plates, which is applied in the field of molded steel plates, can solve the problems of low flatness and low floor strength, and achieve the effect of reducing the requirements of flatness and being convenient for manufacturing and laying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

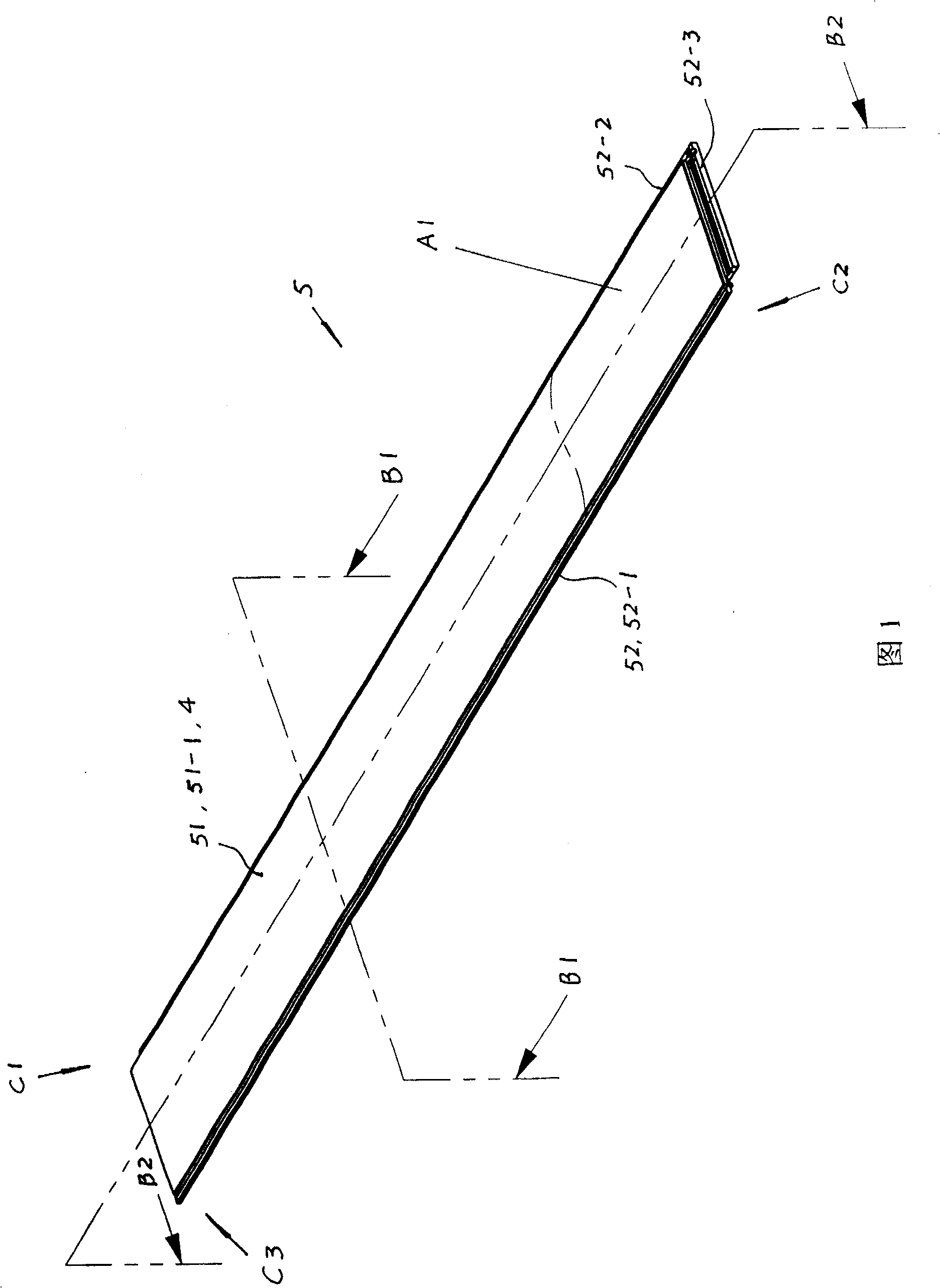

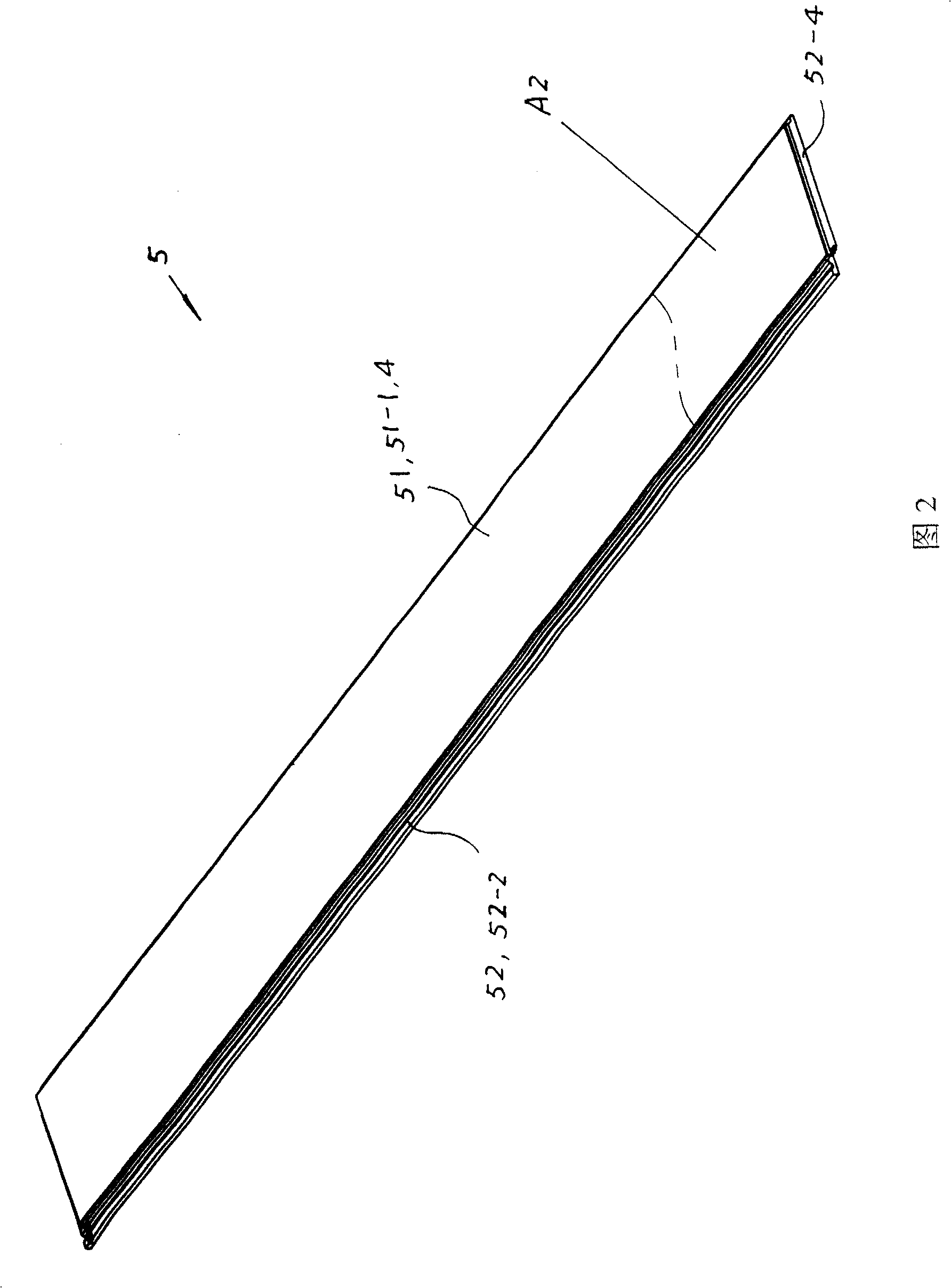

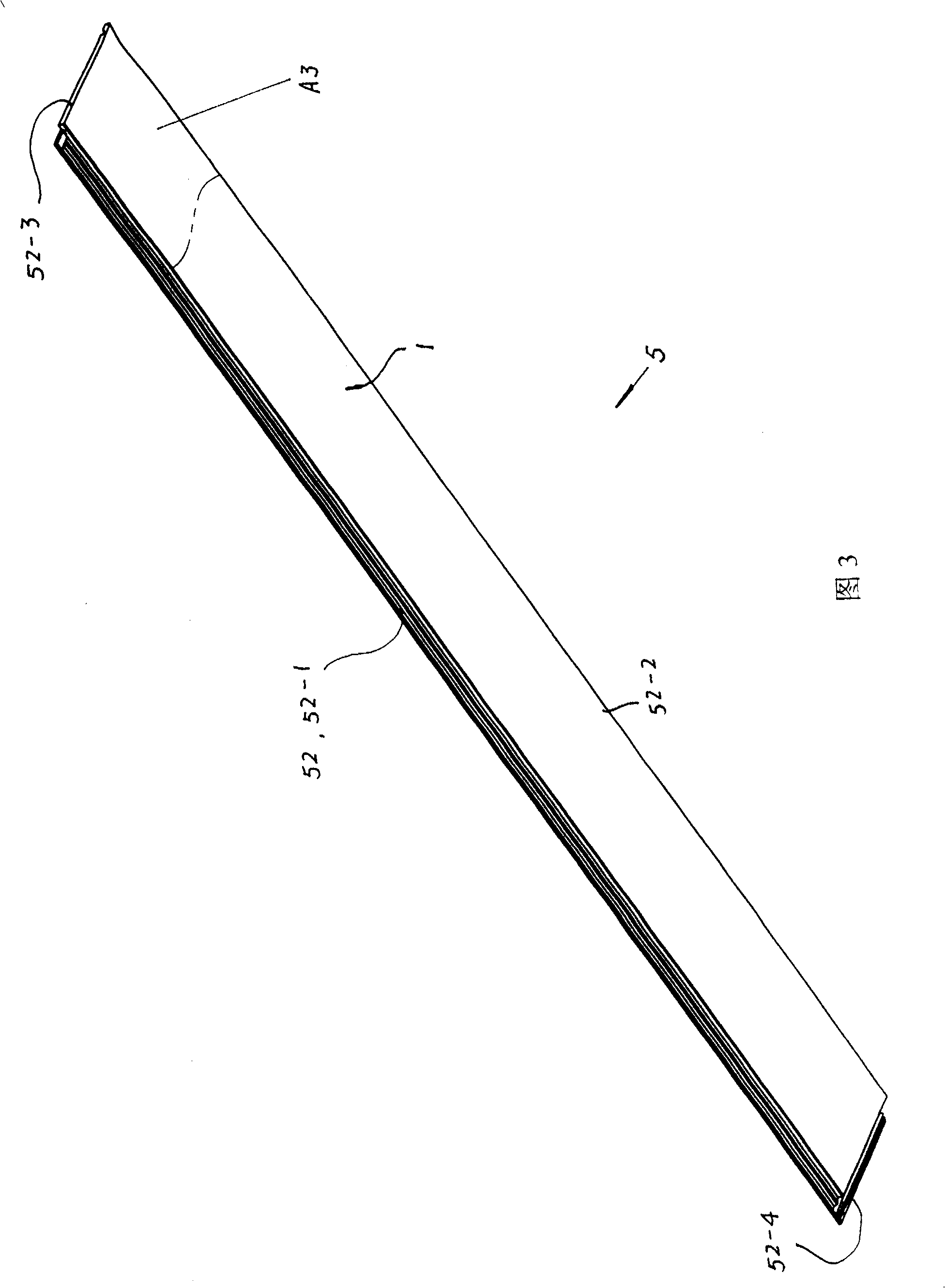

[0047] (Embodiment 1, heat-pressed laminate flooring)

[0048] 1 to 11, the heat-pressed laminate flooring 5 of this embodiment has a balance paper layer 1, a molded fiberboard body 2, a wood grain paper layer 3 and a wear-resistant paper layer 4. The balance paper layer 1 is bonded and fixed on the lower surface of the formed fiberboard body 2; the formed fiberboard body 2 has a fastening part 22; the fastening part 22 is composed of fastening parts arranged on four sides; the fastening part of the formed fiberboard body 2 22 is the fastening part 52 of this hot-pressed laminate flooring 5; It is the buckle tenon 52-1 on the left side of the buckle part 52 of the hot-pressed laminate flooring 5; The fastening groove seat 22-2 together with the part of the balance paper layer 1 below the fastening groove seat 22-2 is the right buckling groove seat 52-2 of the fastening part 52 of the hot-pressed laminate flooring 5; The buckling part 22 of the fiberboard body 2 is the buckli...

Embodiment 2

[0052] (embodiment 2, the upper mold steel plate of hot press)

[0053] Referring to Fig. 12 to Fig. 14, the upper formwork steel plate of this embodiment is basically a rectangular plate body. The upper mold plate 8 has criss-cross ribs 81 arranged on one side of the working surface, which are longitudinal ribs 81-1 and transverse ribs 81-2; the longitudinal ribs 81-1 are consistent with the length direction of the upper mold steel plate 8 And the longitudinal ribs 81-1 are parallel to each other; the transverse ribs 81-2 are consistent with the width direction of the upper formwork steel plate 8 and the transverse ribs 81-2 are parallel to each other. The basic shape of the rib 81 is a "∧" shaped rib with rounded corners, and the rounded corner is located on the top of the "∧" shaped rib 81 . The length (distance between the front and rear edges) a2 of the upper mold steel plate 8 is 2670 mm, the width (distance between the left and right edges) b2 is 1430 mm, and the thick...

Embodiment 3

[0060] (embodiment 3, the upper mold steel plate of hot press)

[0061] The rest are the same as in Example 2, except that the length of the upper die plate 8 is half of that in Embodiment 1, the number of transverse ribs 81-2 of the upper die plate 8 is 2, and the two transverse ribs 81-2 The distance between -2 is the longitudinal width a22; the longitudinal width a22 is still 1205.28 mm. The upper mold steel plate 8 of the present embodiment can still be manufactured by chemical etching, but the cylindrical die 91 of the pressure roller 9 used has only one transverse groove 91-2, and the circumference of the outer peripheral surface of the cylindrical die 91 is 1205.28 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com