Flexible multiplication type organic photoelectric detector and preparation method

A photodetector and flexible technology, applied in photovoltaic power generation, electric solid-state devices, semiconductor/solid-state device manufacturing, etc., can solve the problem of increasing the response time of multiplier devices, and achieve the effect of enhancing electron tunneling injection and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

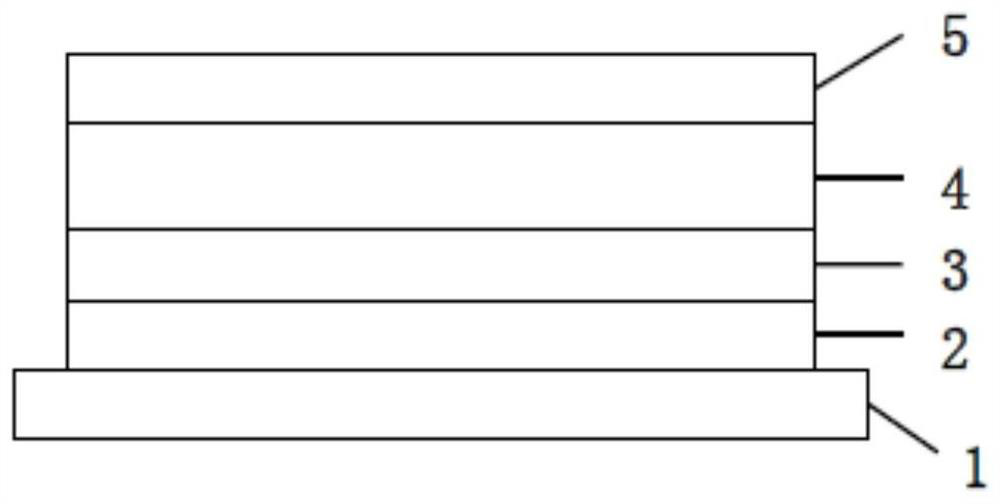

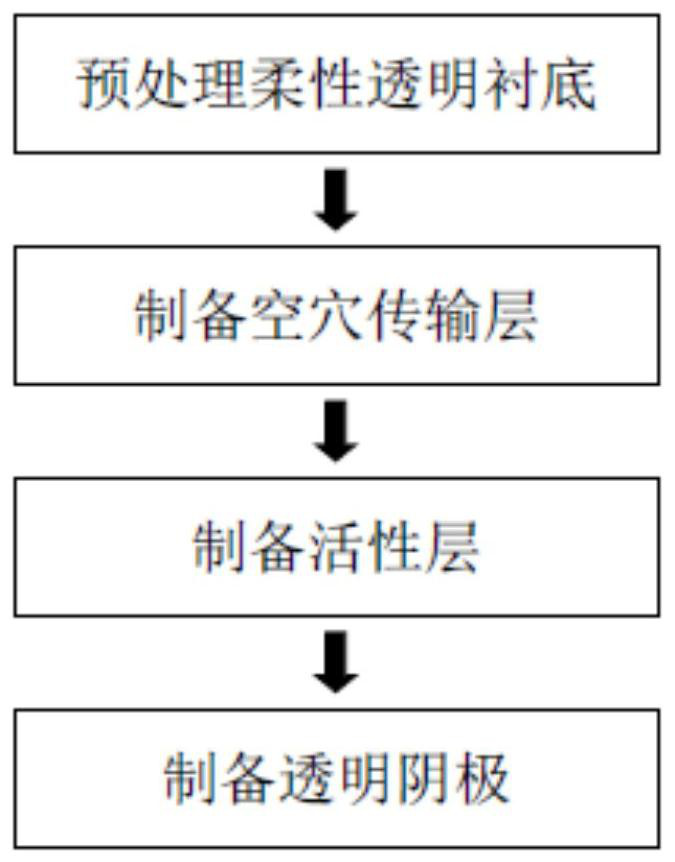

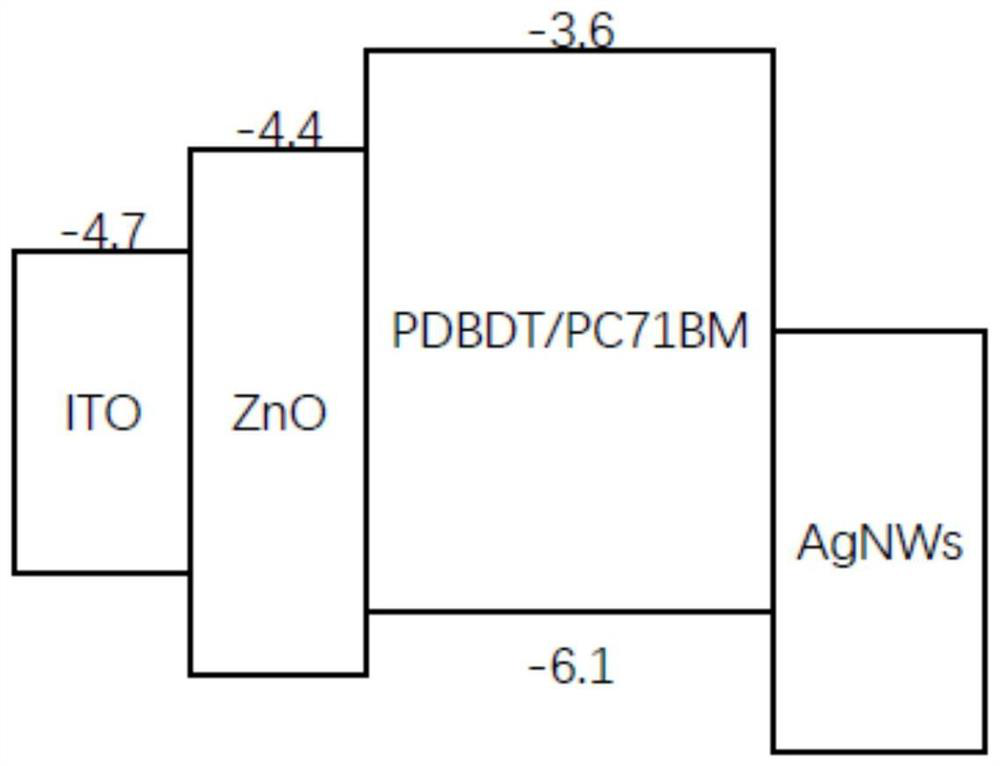

[0033] A flexible multiplication type organic photodetector provided by a preferred embodiment of the present invention includes a flexible transparent substrate layer 1, and a conductive anode layer 2, a hole transport layer 3, an active layer 4, and a conductive cathode layer are sequentially stacked on the flexible transparent substrate layer 1. 5. The active layer 4 is a mixed thin film, the thickness of the mixed thin film is 800-1200nm, and the materials for making the mixed thin film include but not limited to electron donor materials and electron acceptor materials; the electron donor materials and the electron acceptor materials The mass ratio of bulk material is 1:100~10:100. like figure 1 As shown, the flexible transparent substrate layer 1 is made of PET, the conductive anode layer 2 is ITO, the hole transport layer 3 is ZnO, the active layer 4 is a mixed film of PBDB-T and PC71BM, and the conductive cathode layer 5 is silver nanowires.

[0034] Pretreatment of fl...

Embodiment 2

[0041] The device structure diagram and fabrication flow chart described in Embodiment 2 are consistent, only one or more layers of materials or processes are replaced, and are not limited to the disclosed and described specific implementation methods.

[0042] The specific process is as follows:

[0043] 1. Pretreatment of flexible transparent substrate layer 1 with conductive anode layer 2: scrub with detergent and dust-free cloth, then rinse with deionized water to remove oil, dust, fingerprints, etc.; then use deionized water, acetone, isopropyl Alcohols were sonicated for 15 minutes, placed in a drying oven, and dried at 110°C for 60 minutes; the dried transparent substrate was irradiated with UV-ultraviolet light for 15 minutes.

[0044] 2. Prepare the hole transport layer 3 on the above-mentioned conductive anode layer 2: take 40 μL of ZnO solution, spin-coat it on the conductive anode 2 evenly at a rate of 2500 rpm for 25 s; and rapidly anneal at 150 °C in the air atmo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com