Efficient rock breaking PDC drill bit

A drill bit and rock-breaking technology, which is applied in the field of high-efficiency rock-breaking PDC drill bits, can solve the problems of affecting the discharge of cuttings, weakening the service life of the impact device, and hindering the migration of cuttings, so as to improve cutting efficiency, increase service life, and prevent impact. The effect of corrosion failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

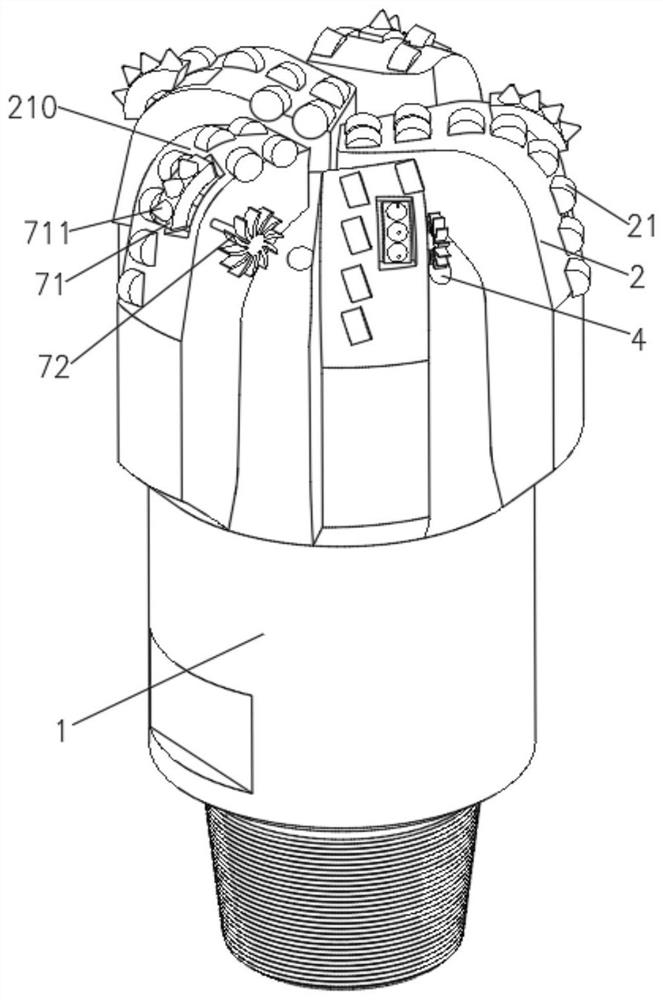

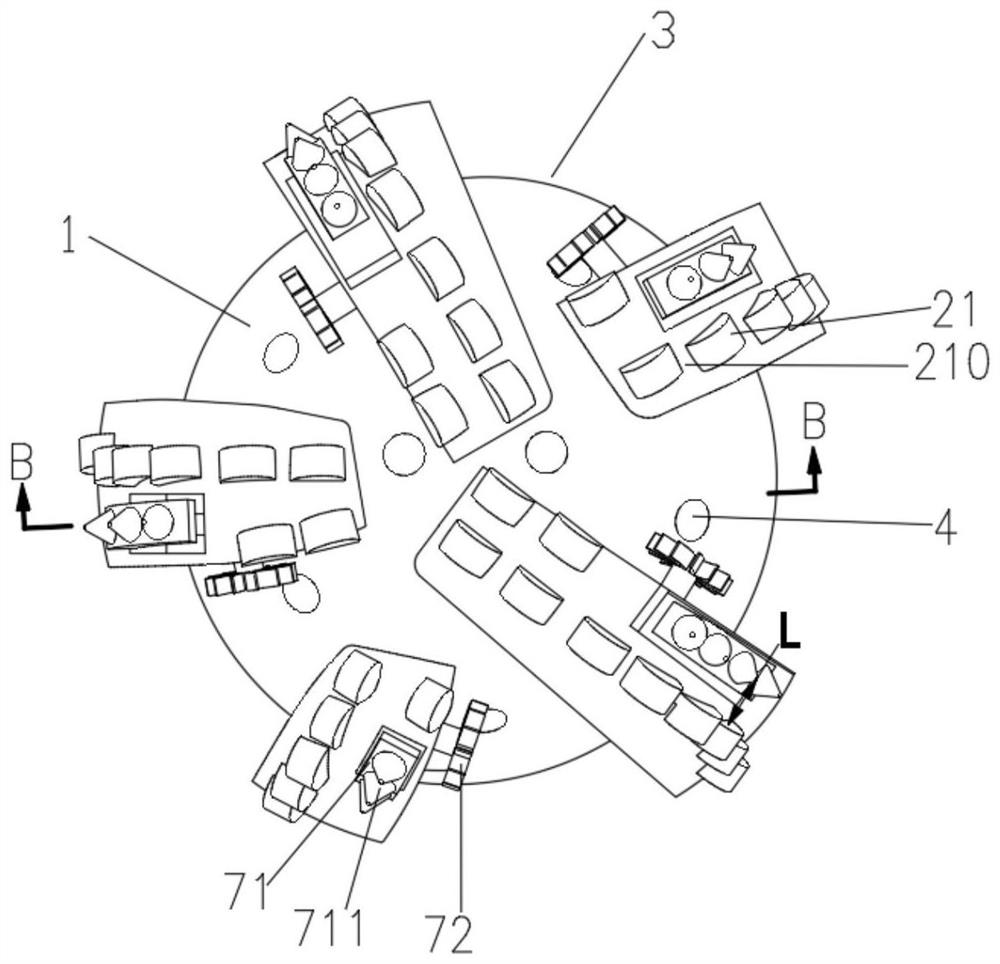

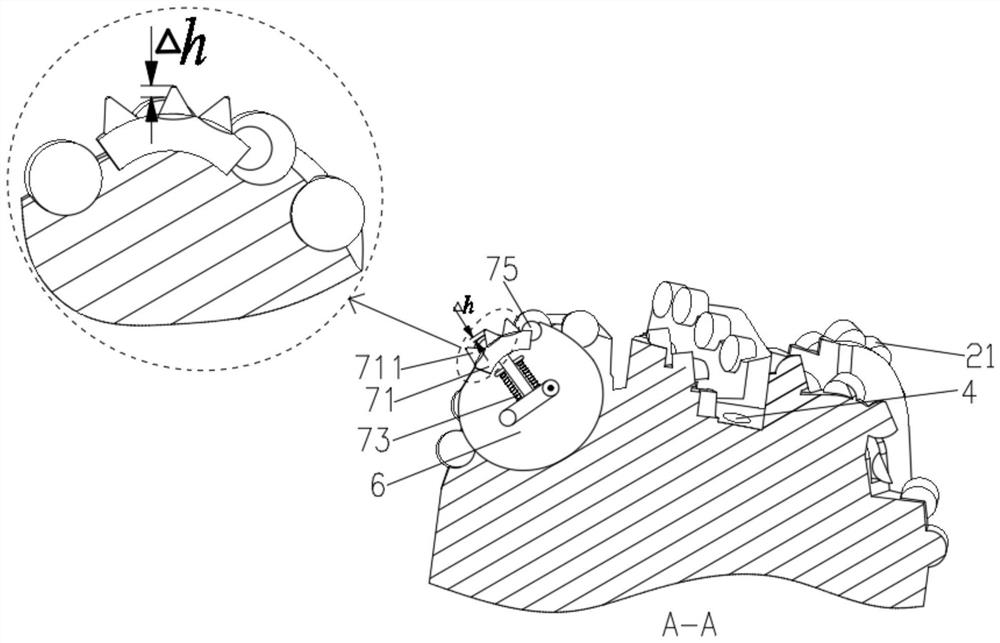

[0041] An embodiment of the present invention provides a high-efficiency rock-breaking PDC drill bit. see figure 1 , 2 , including a bit body 1, extending from the bit body 1 or several blades 2 fixed on the bit body 1, the blade cloth tooth surface 210 is provided with cutting teeth 21, and the drilling fluid is between adjacent blades 2 The flow channel 3 is characterized in that: at least one blade 2 on the drill body 1 is provided with an impact assembly 7, and the impact assembly 7 is composed of an impact device 71, a rolling device 72, and a transmission device 74; The rolling groove 6 is provided, and the impact device 71 rotates with the transmission device 74, and enters into the rolling groove 6 under the action of the matching roller 75; the exposed height of the impact tooth 711 of the impact device 71 is higher than that of the knife The exposed height of the cutting teeth 21 on the wing 2, the height difference is Δh; the impact action of the impact device 71 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com