Female shoe with anti-aging sole and preparation process thereof

A technology of anti-aging, women's shoes, applied in the field of shoes, can solve the problems of the anti-aging performance of the sole affecting the service life of the sole, easy to age, poor anti-aging performance, etc., to improve the anti-aging performance, good weather resistance, and improve anti-aging performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

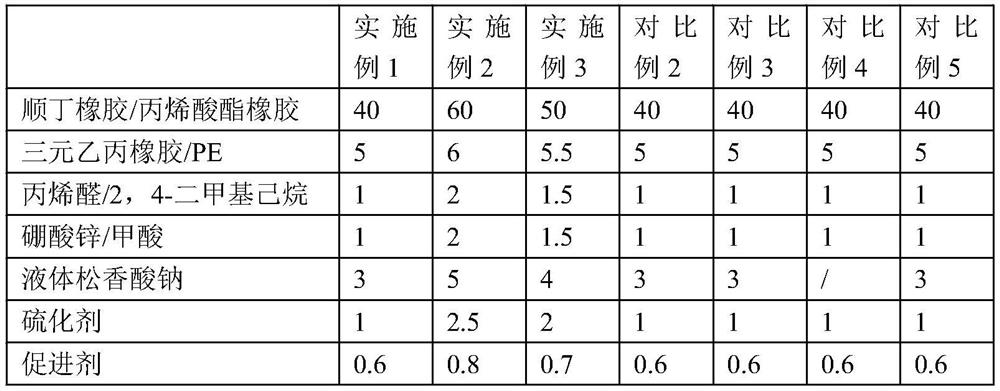

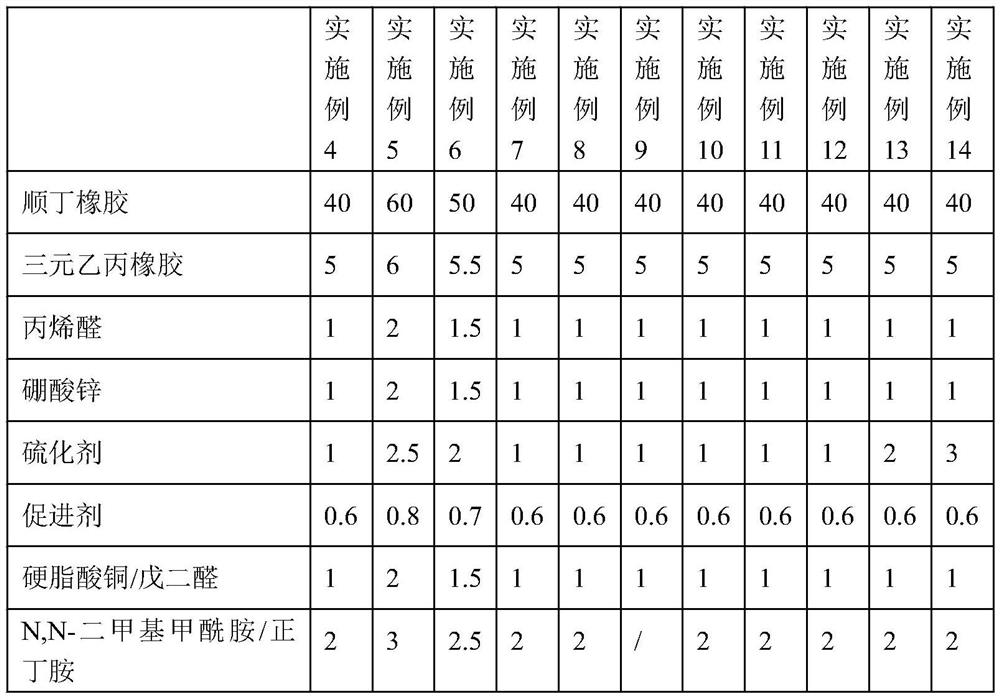

Embodiment 1

[0040] This application discloses an aging-resistant women's shoe with a sole and a preparation process thereof. A women's shoe with an anti-aging sole includes a vamp and a sole, and the sole includes the following raw materials: butadiene rubber; EPDM rubber; acrolein; zinc borate ; Liquid sodium rosinate; Vulcanizing agent; Accelerator DPG; Preparation process comprises the following steps:

[0041] S1. Raw material mixing; first, mix butadiene rubber and EPDM rubber at 150°C and stir for 40 minutes; cool down to 75°C, add acrolein, stir and mix for 40 minutes, and then continue to add zinc borate and liquid sodium rosinate Mix the obtained mixture at 50° C., and finally stir for 1 h to obtain the mixed raw material;

[0042] S2. Vulcanization; continue to add vulcanizing agent and accelerator to the mixed raw materials obtained in S1 and place them in a mold for vulcanization. The first stage of vulcanization is carried out on a flat vulcanizing agent, and the vulcanizatio...

Embodiment 2

[0046] This application discloses an aging-resistant women's shoe with a sole and a preparation process thereof. A women's shoe with an anti-aging sole includes a vamp and a sole, and the sole includes the following raw materials: butadiene rubber; EPDM rubber; acrolein; zinc borate ; Liquid sodium rosinate; Vulcanizing agent; Accelerator ZDC; Preparation process comprises the following steps:

[0047] S1. Raw material mixing; first, mix butadiene rubber and EPDM rubber at 160°C and stir for 60 minutes; cool down to 80°C, add acrolein, stir and mix for 50 minutes, and then continue to add zinc borate and liquid sodium rosinate Mix the obtained mixture at 60° C., and finally stir for 2 hours to obtain the mixed raw material;

[0048] S2. Vulcanization; continue to add vulcanizing agent and accelerator to the mixed raw materials obtained in S1 and place them in a mold for vulcanization. The first stage of vulcanization is carried out on a flat vulcanizing agent, and the vulcaniz...

Embodiment 3

[0052]This application discloses an anti-aging women's shoe with a sole and a preparation process thereof. An anti-aging women's shoe with a sole includes a vamp and a sole. The sole includes the following raw materials: butadiene rubber; EPDM rubber; acrolein; zinc borate ; Liquid sodium rosinate; Vulcanizing agent; Accelerator ZDC; Preparation process comprises the following steps:

[0053] S1. Raw material mixing; first, mix butadiene rubber and EPDM rubber at 155°C and stir for 50 minutes; cool down to 77°C, add acrolein, stir and mix for 45 minutes, and then continue to add zinc borate and liquid sodium rosinate Mix the obtained mixture at 55° C., and finally stir for 1.5 h to obtain the mixed raw material;

[0054] S2. Vulcanization; continue to add vulcanizing agent and accelerator to the mixed raw materials obtained in S1 and place them in a mold for vulcanization. The first-stage vulcanization is carried out on a flat vulcanizing agent, and the vulcanization condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com