A kind of recycled fine aggregate high-strength self-compacting concrete and its preparation method

A self-compacting concrete and recycled fine aggregate technology, applied in the field of concrete, can solve the problems of steel slag being easily corroded, oxidized, safety hazards, and concrete performance degradation, etc., achieve high strength and mechanical properties, improve crack resistance, and avoid corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

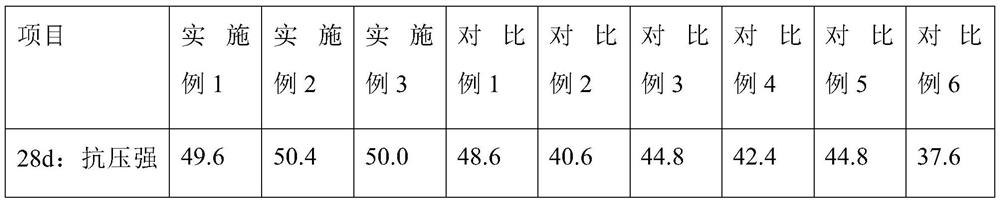

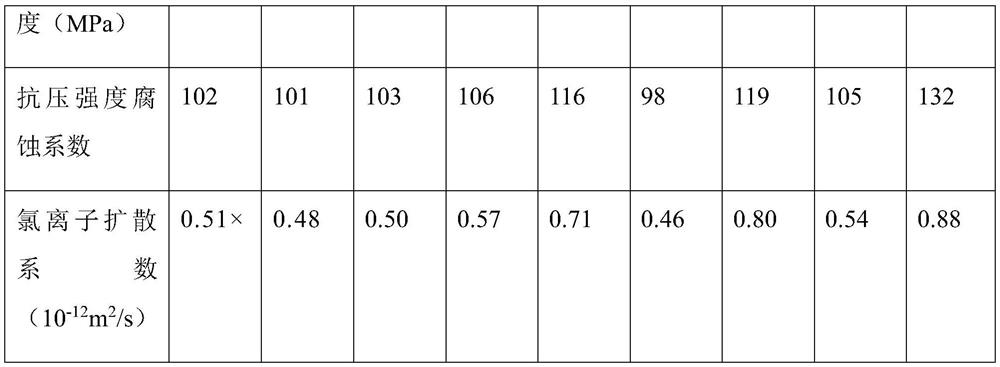

Examples

Embodiment 1

[0046] A method for preparing recycled fine aggregate high-strength self-compacting concrete, comprising the following steps:

[0047] (1) Prepare materials;

[0048] (2) Preparation of modified steel slag fibers:

[0049] Take petroleum ether, methyltrichlorosilane, dimethyldichlorosilane, diphenyldichlorosilane and methylhydrogendichlorosilane, cool down to 0°C in an ice-water bath, mix and stir until dissolved, and then pass in at 4°C Ammonia gas reaction, until the pH is 7, stop feeding nitrogen gas, filter with suction, distill petroleum ether under the protection of nitrogen gas, and obtain polysilazane precursor;

[0050] Take the polysilazane precursor, heat up to 140°C, add steel slag fibers, cover and impregnate for 5 hours, cool down and separate, take out the steel slag fibers and irradiate with ultraviolet light for 48 hours at a wavelength of 250nm to obtain pretreated steel slag fiber;

[0051] Take pretreated steel slag fibers, add toluene diisocyanate after...

Embodiment 2

[0059] A method for preparing recycled fine aggregate high-strength self-compacting concrete, comprising the following steps:

[0060] (1) Prepare materials;

[0061] (2) Preparation of modified steel slag fibers:

[0062] Take petroleum ether, methyltrichlorosilane, dimethyldichlorosilane, diphenyldichlorosilane and methylhydrogendichlorosilane, cool down to 0°C in an ice-water bath, mix and stir until dissolved, and then pass in at 4.5°C Ammonia gas reaction, until the pH is 7, stop feeding nitrogen gas, filter with suction, distill petroleum ether under the protection of nitrogen gas, and obtain polysilazane precursor;

[0063] Take the polysilazane precursor, heat up to 145°C, add steel slag fibers, cover and impregnate for 6 hours, cool down and separate, take out the steel slag fibers and irradiate with ultraviolet light for 49 hours at a wavelength of 253nm to obtain pretreated steel slag fiber;

[0064] Take the pretreated steel slag fiber, add toluene diisocyanate ...

Embodiment 3

[0072] A method for preparing recycled fine aggregate high-strength self-compacting concrete, comprising the following steps:

[0073] (1) Prepare materials;

[0074] (2) Preparation of modified steel slag fibers:

[0075] Take petroleum ether, methyltrichlorosilane, dimethyldichlorosilane, diphenyldichlorosilane and methylhydrogendichlorosilane, cool down to 0°C in an ice-water bath, mix and stir until dissolved, and then pass in at 5°C Ammonia gas reaction, until the pH is 7, stop feeding nitrogen gas, filter with suction, distill petroleum ether under the protection of nitrogen gas, and obtain polysilazane precursor;

[0076] Take the polysilazane precursor, heat up to 150°C, add steel slag fibers, coat and impregnate for 7 hours, cool down and separate, take out the steel slag fibers and irradiate with ultraviolet light for 50 hours at a wavelength of 255nm to obtain pretreated steel slag fiber;

[0077] Take pretreated steel slag fibers, add toluene diisocyanate after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com