A kind of iron ladle and preparation method thereof

A technology for molten iron tanks and castables, which is used in manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problems of harsh refractory requirements for molten iron tanks, large temperature drop of molten iron, and reduction of temperature drop of molten iron, so as to avoid the temperature drop of molten iron. Oversized, reduced mass, increased strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solutions and advantages of the embodiments of the present application clearer, the technical solutions in the embodiments of the present application will be described below in conjunction with the drawings in the embodiments of the present application.

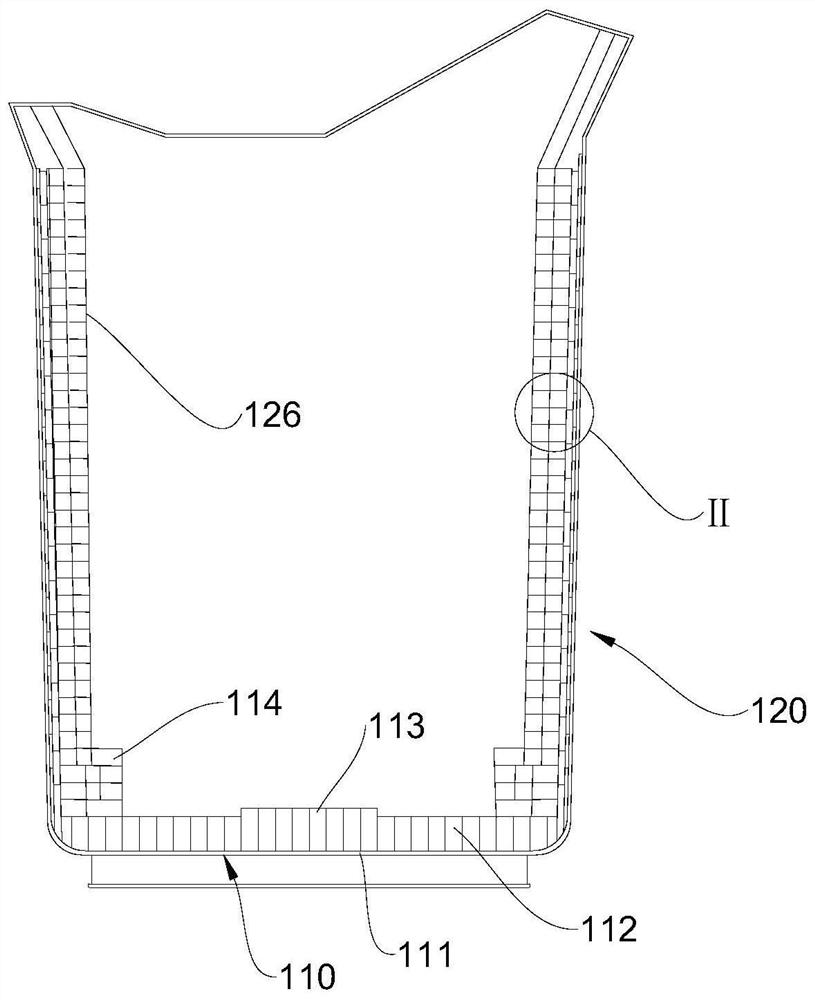

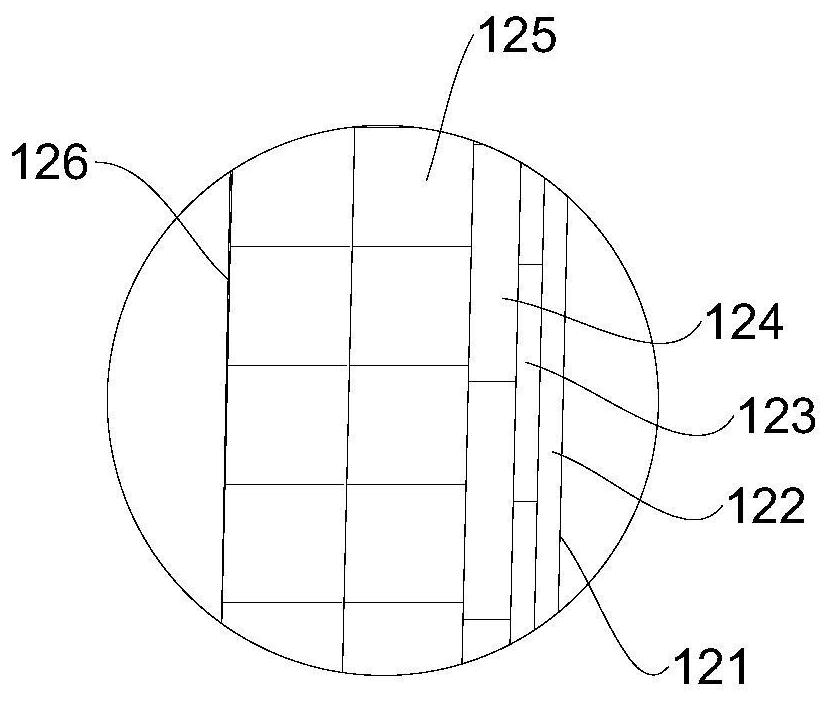

[0025] figure 1 A schematic structural view of the molten iron tank provided in the embodiment of the present application, figure 2 for figure 1 Enlarged view of middle II. see figure 1 and figure 2 , in the embodiment of the present application, the molten iron tank includes a clad bottom 110 and a clad wall 120 . Wherein, the package bottom 110 includes a first cladding 111 and a first working layer 112 from bottom to top. The cladding wall 120 sequentially includes a second cladding 121 , an insulating layer 122 , a permanent layer 123 , a nanometer reflective layer 124 , a second working layer 125 and an anti-slagging coating 126 from outside to inside.

[0026] Where...

PUM

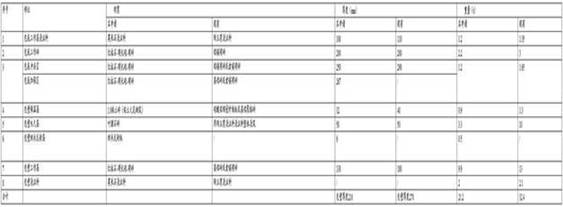

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com