Production system and method for puffed feed for salmons and trouts

A technology of salmon and trout feed and extruded feed, which is applied in the field of extruded feed production equipment, can solve the problems of uneven nutrient content of feed pellets and poor uniformity of feed pellets, and achieve the effects of improving fish meat quality, beautiful feed shape, and reducing deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

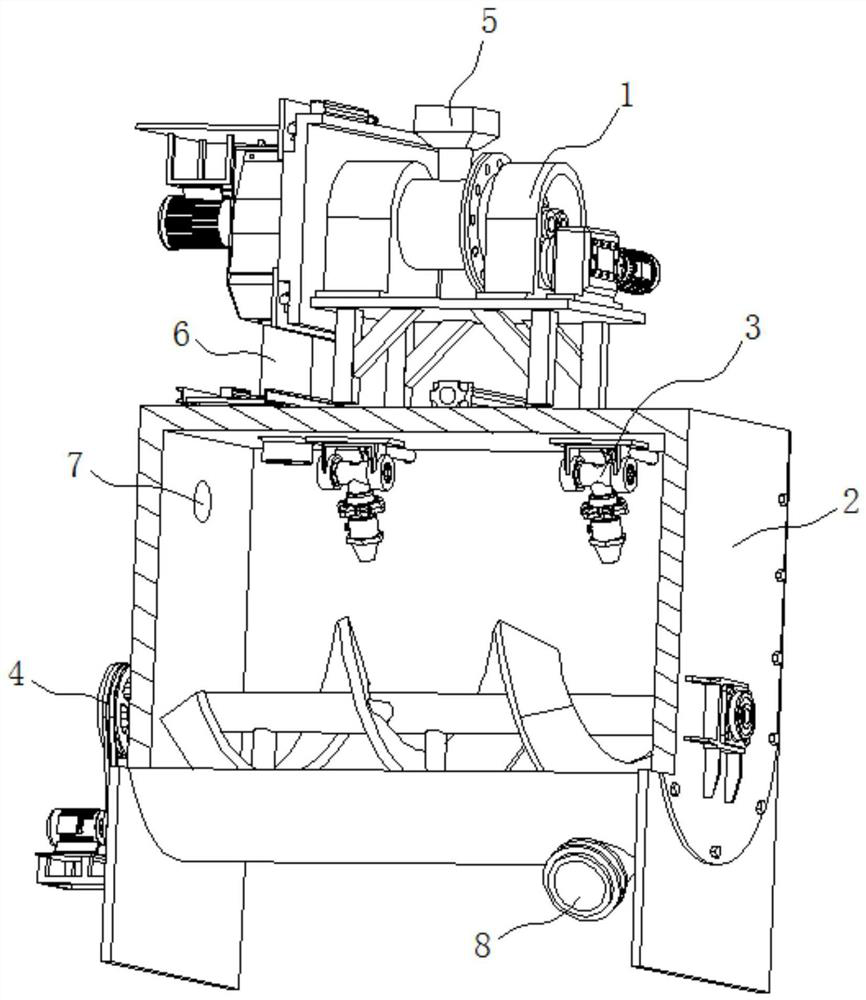

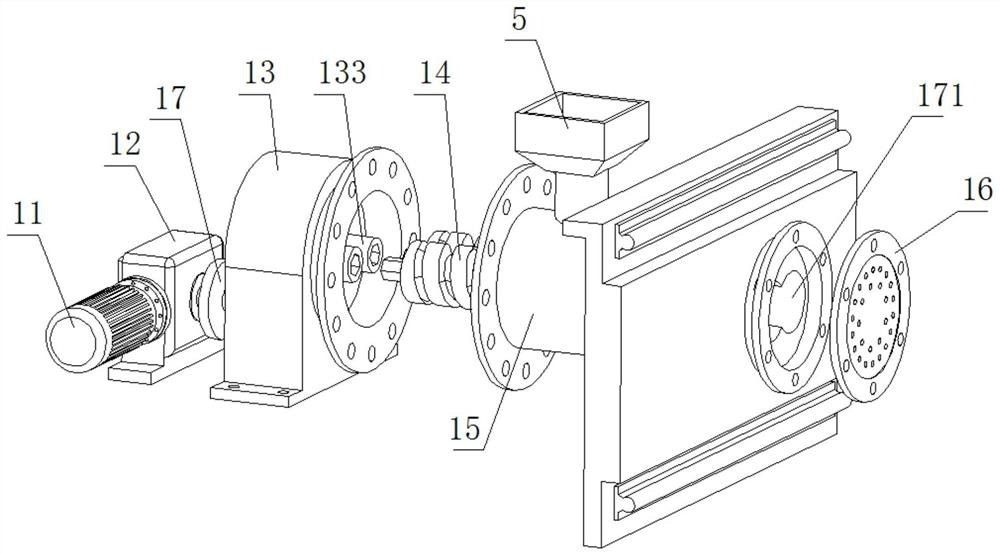

[0059] Specific implementation mode one: refer to Figure 1-14 Describe this embodiment, the production system of the salmon and trout extruded feed of this embodiment, comprise twin-screw extruder mechanism 1, stirring tank 2, vacuum spraying mechanism 3 and agitating mechanism 4, the top of agitating tank 2 is equipped with twin-screw extruding mechanism 1 , the twin-screw extruder mechanism 1 has a material inlet 5 and a material outlet 6, the twin-screw extruder mechanism 1 communicates with the top of the mixing tank 2 through the material outlet 6, and the side wall of the mixing tank 2 is processed with a vacuum port 7, so The vacuum spraying mechanism 3 is installed on the top wall of the stirring tank 2, the stirring tank 2 is equipped with a stirring mechanism 4, and the bottom of the stirring tank 2 has a particle outlet 8. So set, the twin-screw extruder mechanism 1 is used to extrude the mixed salmon and trout feed to form preliminary feed pellets, and then the fe...

specific Embodiment approach 2

[0064] Specific implementation mode two: refer to Figure 1-14 Describe this embodiment, the production system of the salmon trout extruded feed of this embodiment, such as Figure 5As shown, the twin-screw puffing mechanism 1 also includes a particle cutting mechanism 19, and the particle cutting mechanism 19 includes a cutting mechanism mounting table 191, a single-axis slide rail 192, a slider 193, a mounting seat plate 194, and a cutting motor mounting seat 195, cutting motor 196, cutting knife rod 197, cutting knife disc 198, cutting blade 199, material retaining cover 1910 and installation support plate 1911, the cutting mechanism installation table 191 is installed on the extruder shell 15, and the cutting mechanism installation table 191 Two single-axis slide rails 192 arranged in parallel are installed on the top, the installation seat plate 194 is installed on the single-axis center slide rail 192 through a slider 193, and an installation support plate 1911 and a mat...

specific Embodiment approach 3

[0066] Specific implementation mode three: refer to Figure 1-14 Describe this embodiment, the production system of the extruded feed for salmon and trout in this embodiment, the bottom of the material retaining cover 1910 has a first discharge cylinder 1912, and the side wall of the material retaining cover 1910 is processed with a square notch 1913. A rubber blocking sheet 1914 is installed at the notch 1913 . In this way, the material blocking cover 1910 is used to accept the extruded and cut feed pellets, and the pellets are input into the mixing tank 2 through the discharge port 6;

[0067] When the material blocking cover 1910 shields the extrusion die 6, the first discharge cylinder 1912 installed at the bottom of the material blocking cover 1910 communicates with the discharge port 6, and the feed particles directly enter the discharge port 6 through the first discharge cylinder 1912 Inside; when the material retaining cover 1910 moves to the edge (such as Figure 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com