A bolt transformation type anti-buckling energy-dissipating support and its manufacturing process

A technology of anti-buckling energy dissipation and manufacturing process, applied in earthquake-proof, bridge parts, building components, etc., can solve problems such as residual stress of supporting core force-bearing members, poor ductility, durability and seismic performance of anti-buckling energy-dissipating supports , to avoid residual deformation and residual stress of welds, facilitate replacement work, and achieve the effect of making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

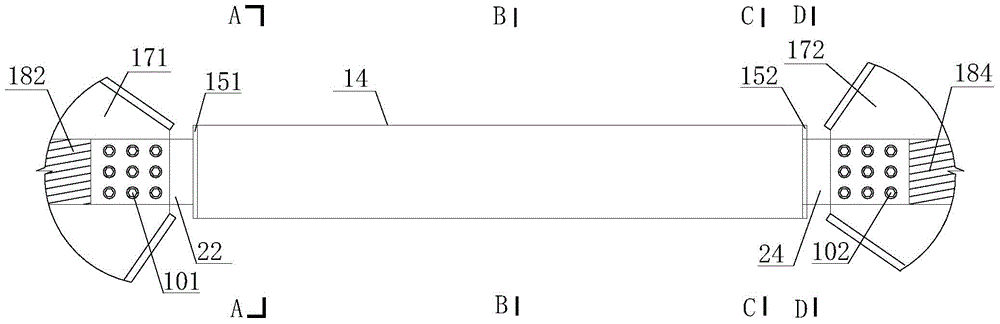

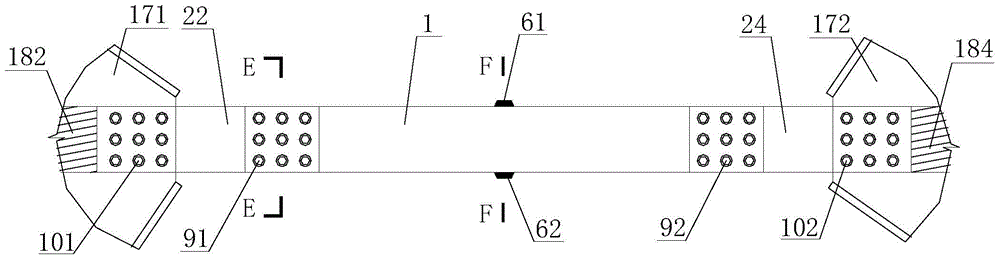

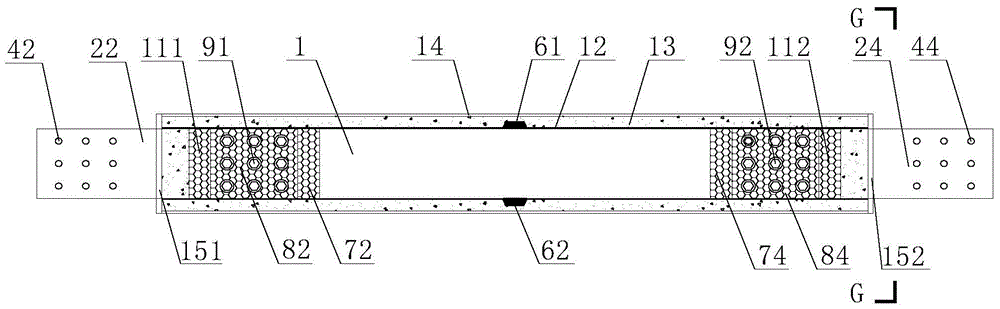

[0044] refer to Figure 1 to Figure 10 , a bolt conversion type buckling-resistant energy-dissipating support, including a core stress unit 1, a constraint unit located at the periphery of the core stress unit, and conversion devices located at both ends of the core stress unit, and the core stress unit 1 is "one" A steel plate in the form of a glyph cross-section, bolt holes are respectively provided at both ends of the core force-bearing unit 1, and a core material compression material is provided at the end of the core force-bearing unit 1, and the conversion device includes a first conversion plate and the second conversion plate, the core force unit is located between the first conversion plate and the second conversion plate and the inner end of the first conversion plate, the end of the core force unit 1, The inner end of the second conversion plate is connected; the nut end and the nut section of the first conversion bolt group are respectively provided with bolt compr...

example 1

[0073] Example 1: The core stress unit 1 is relatively thick, and the core stress unit 1 is made of Q235D steel, with a thickness of 28mm, a length of 3500mm, and a height of 200mm; The first conversion plate 23 and the second right conversion plate 24 are both made of Q235D steel, with a thickness of 20mm, a height of 200mm, and a length of 650mm; the unbonded material layer 12 is made of soft glass with a thickness of 2mm; the grouting material 13 is made of fine stone concrete; the conversion left The first bolt hole 31, the conversion left to the second bolt hole 32, the conversion right to the first bolt hole 33, the conversion right to the second bolt hole 34, the left bolt hole 51, the right bolt hole 52, the left first connecting bolt hole 41. Three rows of bolt holes are used for the second left connecting bolt hole 42, the first right connecting bolt hole 43 and the second right connecting bolt hole 44, the hole diameter is 28mm, the distance between the centers of th...

example 2

[0074]Example 2: The core stress unit 1 is relatively thin, and the core stress unit 1 is made of Q235D steel, with a thickness of 6mm, a length of 1000mm, and a height of 80mm; Both the first transformation plate 23 and the second right transformation plate 24 are made of Q235D steel, with a thickness of 12mm, a height of 80mm, and a length of 200mm; the non-adhesive material layer 12 is made of soft glass with a thickness of 0.5mm; the grouting material 13 is made of mortar; One bolt hole 31, conversion left to the second bolt hole 32, conversion right to the first bolt hole 33, conversion right to the second bolt hole 34, left bolt hole 51, right bolt hole 52, left to the first connecting bolt hole 41 , The second left connecting bolt hole 42, the first right connecting bolt hole 43 and the second right connecting bolt hole 44 adopt three rows of bolt holes, the hole diameter is 11mm, the bolt hole center distance is 26.5mm, and the bolt hole distance is left The distance f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com