SMT process prediction tool for intelligently deciding PCB quality

A technology of intelligent decision-making and tools, applied in CAD circuit design, sustainable manufacturing/processing, biological neural network models, etc., can solve problems such as limited product quality, many influencing factors, and increased production costs, so as to improve the level of intelligence, Accurate process parameters and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

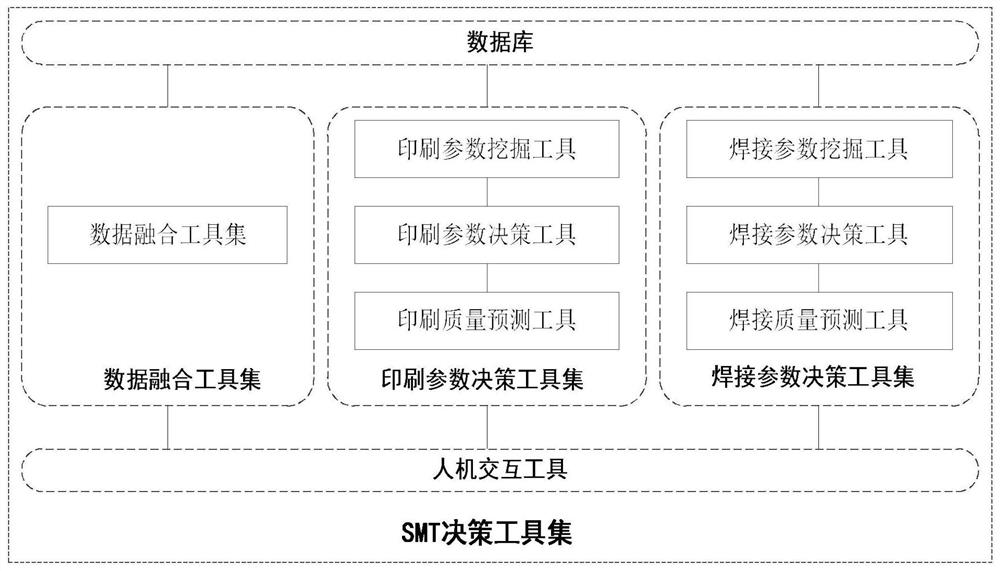

[0013] refer to figure 1 . In the preferred embodiment described below, an SMT process prediction tool for intelligent decision-making of PCB quality includes: a data fusion tool set communicating with a database, a printing parameter decision tool set, a welding parameter decision tool set, and a human-computer interaction tool set The software layer of the SMT intelligent decision-making tool set is characterized in that: the data fusion tool automatically reads the size parameters and component information on the design conditions of the printed board to be assembled through the database, and forms the design conditions of different components for the software execution layer List, the printing parameter decision-making tool set and welding parameter decision-making tool set in the software execution layer, according to the design conditions of the components on the printed board to be assembled, compare with the printing and welding data of the historical components under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com