Preparation method and application of microneedle electrode

An electrode and microneedle technology, which is applied in the field of preparation of microneedle electrodes, can solve problems such as limiting the analytical sensitivity of electrochemical biosensors, achieve good electrocatalytic properties and improve detection sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Synthesis of platinum wire microneedle electrodes and silver / silver chloride wire microneedle electrodes:

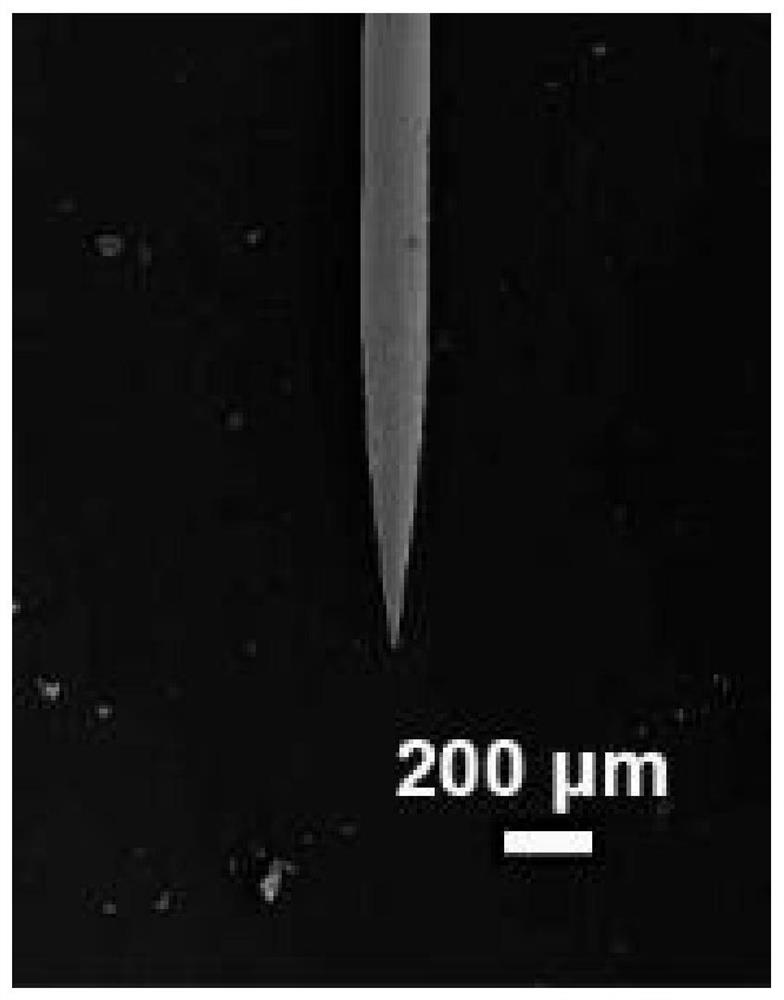

[0032] Melt platinum with a purity of 99.999% at high temperature to obtain liquid platinum, and then carry out the process of pressing square strips → wire drawing → shaping → grinding to obtain such figure 1 The lower diameter shown is a 200 μm platinum wire microneedle electrode. In the same way, 99.999% pure silver is melted at high temperature to obtain liquid silver, and then the process of pressing square bar → wire drawing → shaping → grinding process is obtained as follows: figure 1 The silver wire microneedle shown is followed by the silver wire microneedle in 1mol / L potassium chloride solution, under the voltage of -0.1V, the constant potential deposition is 1000s, and the silver / silver chloride electrode is obtained as the reference electrode .

[0033] (2) Synthesis of polydopamine spheres-gold nanocomposites:

[0034] Dopamine was dissolved in...

Embodiment example 2

[0040] (1) Synthesis of platinum wire microneedle electrodes and silver / silver chloride wire microneedle electrodes:

[0041] Melt platinum with a purity of 99.999% at high temperature to obtain liquid platinum, and then carry out the process of pressing square strips → wire drawing → shaping → grinding to obtain such figure 1 A platinum wire microneedle electrode with a diameter of 200 μm is shown. In the same way, 99.999% pure silver is melted at high temperature to obtain liquid silver, and then the process of pressing square bar → wire drawing → shaping → grinding process is obtained as follows: figure 1 The silver wire microneedle shown is followed by the silver wire microneedle in 1mol / L potassium chloride solution, under the voltage of -0.1V, the constant potential deposition is 1000s, and the silver / silver chloride electrode is obtained as the reference electrode .

[0042] (2) Synthesis of polydopamine spheres-gold nanocomposites:

[0043] Dopamine was dissolved in d...

Embodiment example 3

[0049] (1) Synthesis of platinum wire microneedle electrodes and silver / silver chloride wire microneedle electrodes:

[0050] Melt platinum with a purity of 99.999% at high temperature to obtain liquid platinum, and then carry out the process of pressing square strips → wire drawing → shaping → grinding to obtain such figure 1 A platinum wire microneedle electrode with a diameter of 50 μm under the structure shown. In the same way, 99.999% pure silver is melted at high temperature to obtain liquid silver, and then the process of pressing square bar → wire drawing → shaping → grinding process is obtained as follows: figure 1 The silver wire microneedle shown is followed by the silver wire microneedle in 1mol / L potassium chloride solution, under the voltage of -0.1V, the constant potential deposition is 1000s, and the silver / silver chloride electrode is obtained as the reference electrode .

[0051] (2) Synthesis of polydopamine spheres-gold nanocomposites:

[0052] Dopamine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com