Cement-based spraying material and preparation method and application thereof

A spraying material, cement-based technology, applied in the direction of cement coatings, etc., can solve the problems of sprayed coatings such as easy cracking under pressure, poor bearing capacity, and long setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

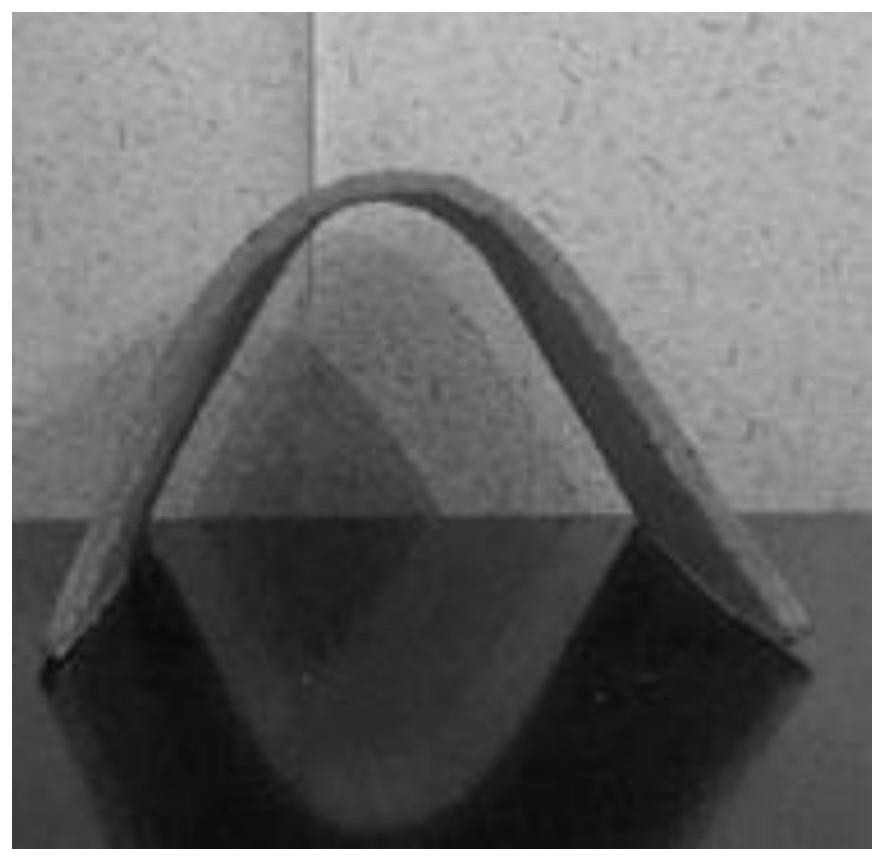

Image

Examples

Embodiment 1

[0034] Pour 70 parts of cement, 2 parts of potassium persulfate / sodium sulfite with a mass ratio of 1:1, 1 part of naphthalene-based water reducer and 2 parts of sodium carbonate / calcium chloride with a mass ratio of 1:1 into the mixer Stir and mix for 30 minutes to obtain component A. Stir and mix 30 parts of acrylamide, 2 parts of N,N-dimethylbisacrylamide and 60 parts of water for 40 minutes to completely dissolve to obtain component B. Pour component A into the mixing chamber of the spraying equipment, start stirring at a slow speed, add component B at the same time, stir while adding, stirring for 2 minutes, and then spray the material, the spraying distance is 1.5m, and the spraying thickness is 3mm.

Embodiment 2

[0036] Pour 60 parts of cement, 3 parts of ammonium persulfate, 1 part of naphthalene-based water reducer and 1 part of calcium fluoroaluminate into a mixer and mix for 30 minutes to obtain component A. Stir and mix 40 parts of acrylic acid, 4 parts of aziridine cross-linking agent and 70 parts of water for 30 minutes, completely dissolve to obtain component B. Pour component A into the mixing chamber of the spraying equipment, start stirring at a slow speed, and add component B at the same time, stirring while adding, stirring for 2 minutes, and then spraying and beating, the spraying distance is 2m, and the spraying thickness is 2mm.

Embodiment 3

[0038] Pour 70 parts of cement, 4 parts of potassium persulfate / sodium sulfite with a mass ratio of 1:1, 2 parts of naphthalene-based water reducer and 3 parts of sodium carbonate into the mixer and stir for 20 minutes to obtain component A. Stir and mix 40 parts of acrylic acid / acrylamide with a mass ratio of 1:1, 3 parts of N,N-dimethylbisacrylamide and 70 parts of water for 30 minutes, and completely dissolve to obtain component B. Pour component A into the mixing bin of the spraying equipment, start stirring at a slow speed, and add component B at the same time, stirring while adding, stirring for 2 minutes, and then spraying and beating, the spraying distance is 3m, and the spraying thickness is 4mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com