Preparation method of ammonium nitrate assisted macroporous thin-layer carbon

A technology of ammonium nitrate and thin layer, which is applied in the preparation/purification of carbon, electrical components, antennas, etc. It can solve the problems of poor absorbing performance, large constant, and unfavorable impedance matching, so as to improve the degree of impedance matching and improve the dispersion , the effect of easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Dissolve 1 g of glucose and 2 g of zinc nitrate in 20 ml of deionized water, sonicate for 15 minutes, and mix well. The prepared solution was moved to a blast drying oven, dried at 120 degrees Celsius for 7 hours, and complexed and foamed at low temperature to obtain a lightweight expansion precursor. The prepared expanded body was transferred to a tube furnace for heating, heated to 900°C at 5° / min under nitrogen atmosphere, and kept at 900°C for 2 hours. The composite wave absorbing material is obtained after heat treatment. The prepared composite wave absorbing material and paraffin were heated according to the ratio of material: paraffin = 1:8 until they were evenly mixed, and pressed into a ring tube with an outer diameter of 7.0 mm and an inner diameter of 3.0 mm to test the wave absorption performance.

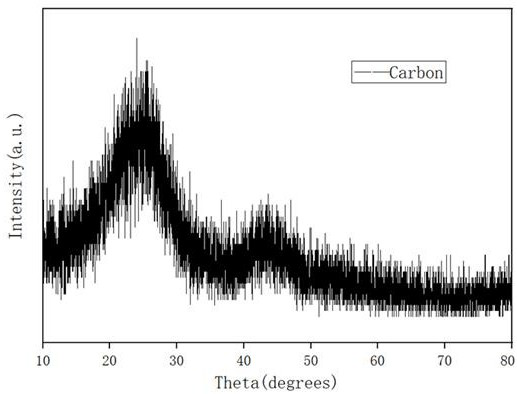

[0024] figure 1 It shows that when the thickness is 4.5mm, the reflection attenuation can reach -44.2dB, and the corresponding bandwidth is 4.8GHz, showing exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com