Production line for crane main beam stiffened plate

A crane and production line technology, applied in the direction of auxiliary equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low work efficiency, easy toppling of ribs to be welded, inability to remove ribs and welding streamlined production, etc. problems, to achieve the effect of improving welding quality, improving working conditions and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

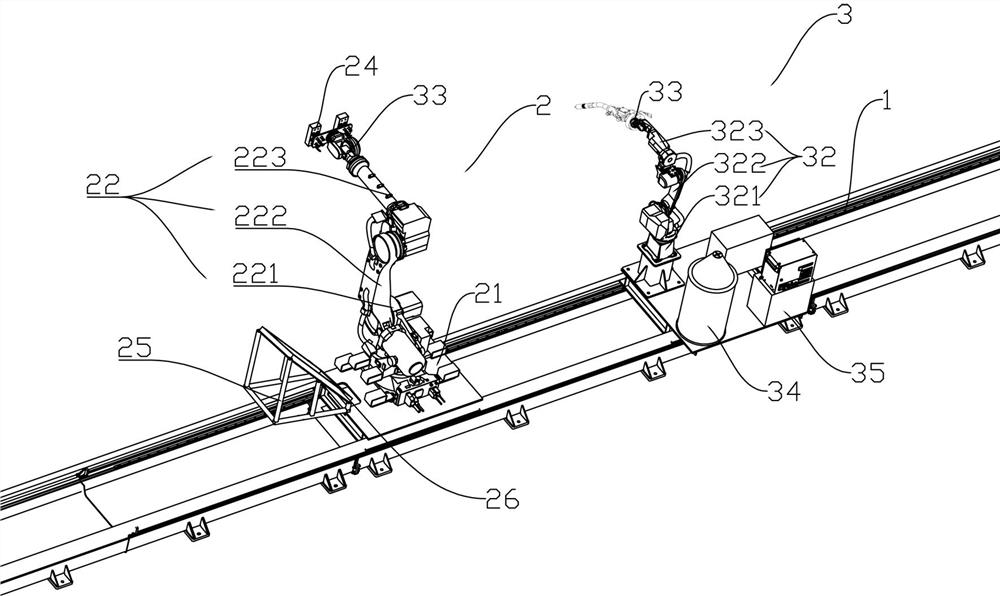

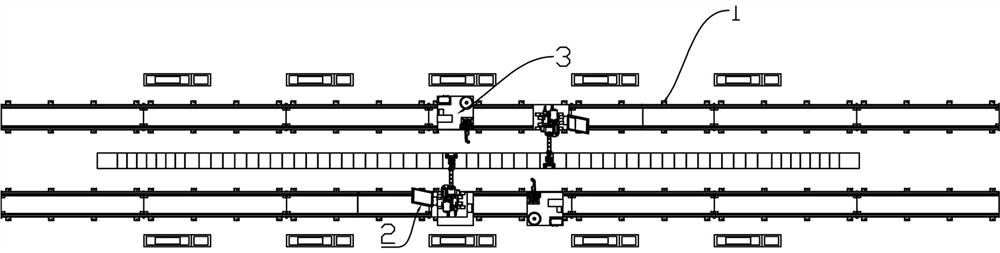

[0031] The specific embodiment of the production line of the girder of the crane girder planting ribs of the present invention, as Figure 1 to Figure 6 As shown, the production line of crane girder reinforcement boards includes two sets of line rails 1 arranged in parallel. Preferably, each set of line rails 1 includes two parallel tracks to ensure that the workpieces fixed thereon are more stable. The rib plate positioning device 2 is fixed on the line rail 1 and cooperates with its lateral guide movement. The rib plate positioning device 2 includes a positioning base 21 that cooperates with the guide shift of the line rail 1. The rotation center line at the top of the positioning base 21 extends vertically. There is a positioning mechanical arm 22, and the positioning mechanical arm 22 includes a positioning fixed arm 221, a positioning connecting arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com