A kind of preparation method of sandwich structure superhydrophilic copper foam with capillary effect

A technology of capillary effect and sandwich, which is applied in the field of heat and mass transfer, can solve problems such as difficulty in guaranteeing the quality of vapor chamber finished products, unfavorable cooling liquid flow, poor pore connectivity, etc., and achieve excellent hydrophilicity and capillary effect, products The effect of good quality and structural stability and stable overall heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing superhydrophilic copper with a sandwich structure comprising the steps of:

[0036] (1) In parts by weight, 80 parts of copper powder with an average particle size of 400nm, 10 parts of ammonium chloride and 5 parts of deionized water were mixed and stirred evenly, and vacuum defoaming was performed to form a viscous mixture for later use.

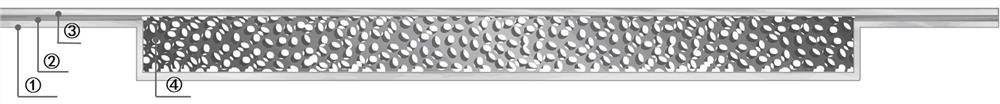

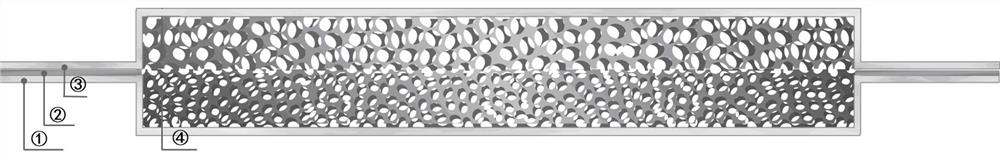

[0037] (2) Mechanically stamp ordinary copper foil to form a flat-bottomed groove structure with a low middle and high surroundings, as the lower plate ①. There is an outlet on the edge of the groove structure of the lower plate ①, which is used as a gas channel or a liquid injection port.

[0038] (3) Pour the viscous mixture into the groove of the lower plate ①, fill the groove completely, and compact it flat (middle layer).

[0039] (4) Evenly spread a thin layer of nano-copper solder paste layer ② around the upper surface of the lower board ① (except for the reserved outlet); place another flat copper foi...

Embodiment 2

[0042] A method for preparing superhydrophilic copper with a sandwich structure comprising the steps of:

[0043] (1) In parts by weight, 80 parts of copper powder with an average particle size of 400 nm, 10 parts of ammonium chloride and 5 parts of deionized water were mixed and stirred evenly, and vacuum defoaming was performed to form a viscous mixture for later use.

[0044] (2) Mechanically stamp ordinary copper foil to form a flat-bottomed groove structure with a low middle and high surroundings, as the lower plate ①. There is an outlet on the edge of the lower plate ① flat-bottomed groove structure, which is used as a gas channel or a liquid injection port.

[0045](3) Pour the viscous mixture into the groove of the lower plate ①, fill the groove completely, and compact it flat (middle layer); spread evenly around the upper surface of the lower plate ① (except for the reserved outlet) A thin layer of nano-copper solder paste②.

[0046] (4) Similarly, pour the viscous ...

Embodiment 3

[0049] A method for preparing superhydrophilic copper with a sandwich structure comprising the steps of:

[0050] (1) In parts by weight, 80 parts of copper powder with an average particle size of 400 nm, 10 parts of ammonium chloride and 5 parts of deionized water were mixed and stirred evenly, and vacuum defoaming was performed to form a viscous mixture W1.

[0051] (2) Mechanically stamp ordinary copper foil to form a flat-bottomed groove structure with a low middle and high surroundings, as the lower plate ①. There is an outlet on the edge of the lower plate ① flat-bottomed groove structure (around the flat-bottomed groove, that is, the side), as a gas channel or a liquid injection port.

[0052] (3) Pour the viscous mixture W1 into the groove of the lower plate ①, fill the groove completely, and compact it flat (middle layer); spread evenly around the upper surface of the lower plate ① (except for the reserved outlet) A thin layer of nano-copper solder paste layer②.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com