Tinting device for high-hardness and high-brightness gold jewelry

A high-brightness, high-hardness technology, applied in the field of gold jewelry hanging color, can solve the problem of inconvenient addition of concentrated sulfuric acid reagents, and achieve the effect of stable and fast fixing of the crucible, prevention of concentrated acid splashing, and fast and safe addition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

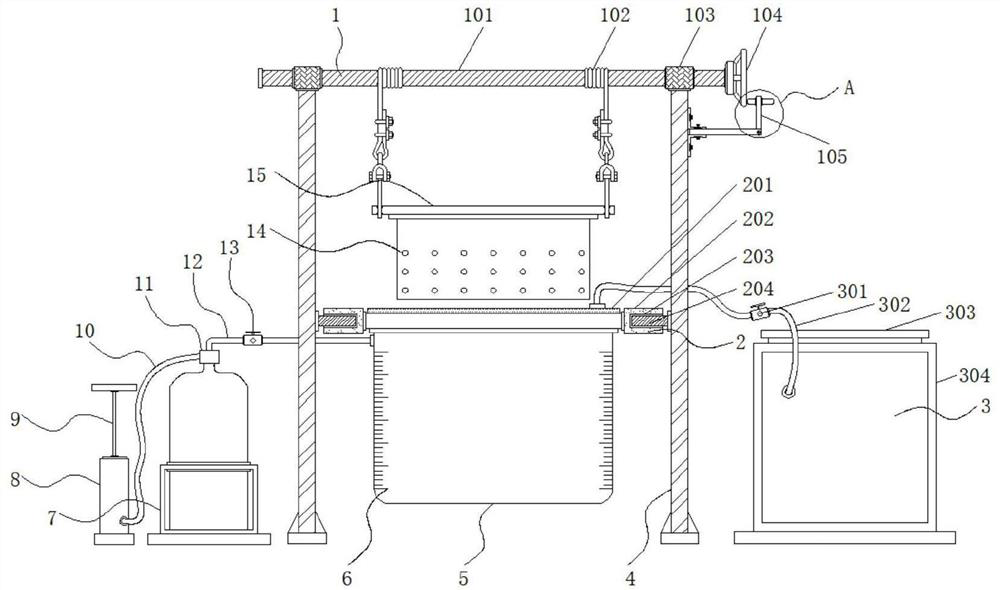

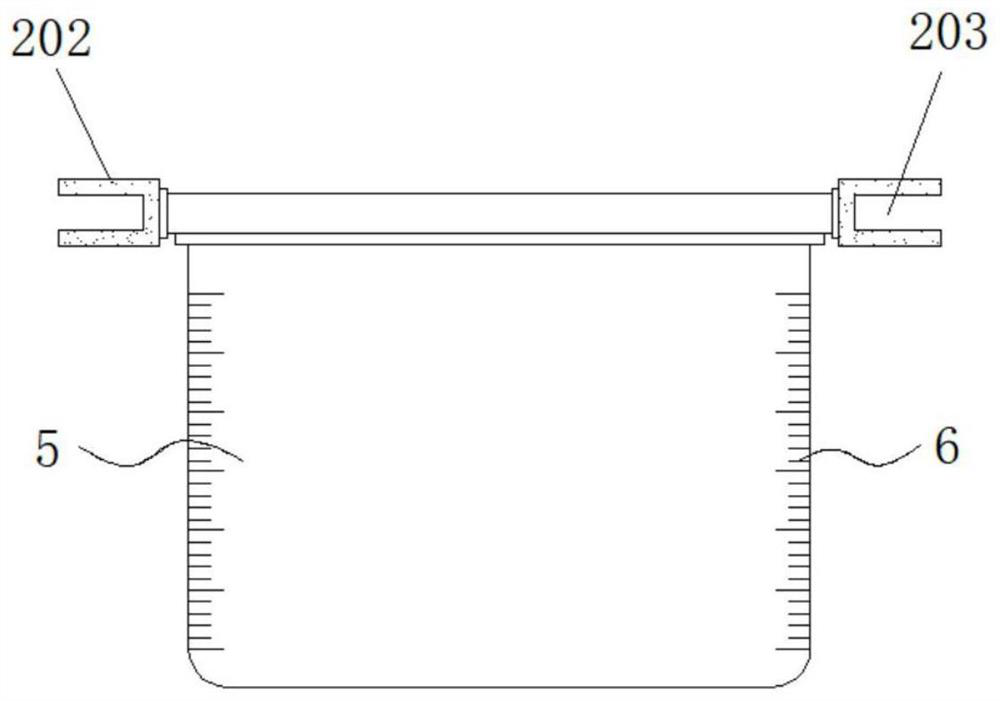

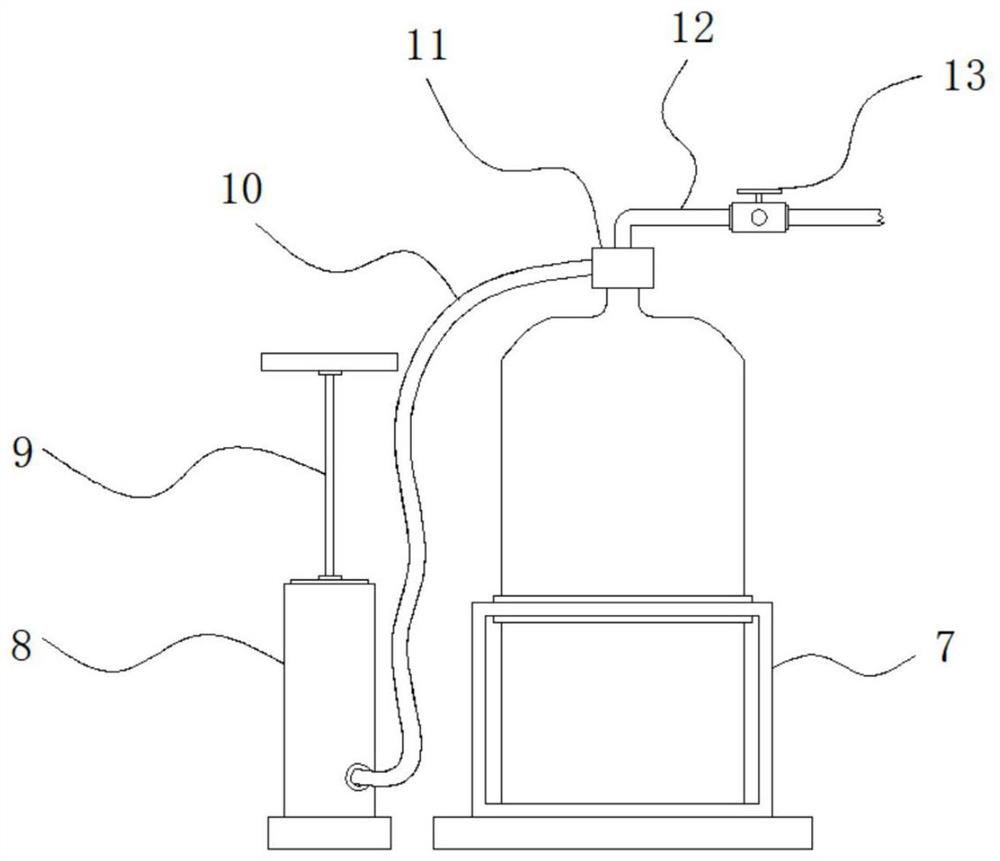

[0035] Example 1: See Figure 1-6 , a high-hardness, high-brightness gold jewelry hanging color device, including a quartz crucible 5 and a quartz holding bucket 15, the two sides of the top of the quartz crucible 5 are provided with an installation structure 2, the outside of the quartz crucible 5 is provided with a scale 6, and the quartz crucible 5 is provided with a scale 6. Both sides of the crucible 5 are provided with a fixed frame 4, the top of the fixed frame 4 is provided with a non-contact lifting structure 1, a quartz holding bucket 15 is arranged above the quartz crucible 5, and a drain hole 14 is arranged inside the quartz holding bucket 15 One side of the fixed frame 4 is provided with an acid gas collection structure 3, and the other side of the fixed frame 4 is provided with a concentrated sulfuric acid addition structure;

[0036] see Figure 1-6A hanging color device for high hardness and high brightness gold jewelry also includes a concentrated sulfuric ac...

Embodiment 2

[0039] Embodiment 2: the quartz holding bucket 15 and the quartz crucible 5 are cylindrical, and the radii of the top and the bottom of the quartz holding bucket 15 are smaller than the top and the bottom of the quartz crucible 5 respectively;

[0040] Drainage holes 14 are equidistantly distributed around the quartz holding bucket 15;

[0041] Specifically, such as figure 1 , figure 2 , Figure 4 , Figure 5 and Figure 6 As shown, when the suspension rope 102 is unwound and the quartz holding bucket 15 descends to the inside of the quartz crucible 5, the high-concentration sulfuric acid reagent is immersed into the surface of the gold jewelry through the drain hole 14, and the gold jewelry is soaked and hung, and the hanging color is completed. Along with the slow winding of sling 102, sulfuric acid reagent leaks back to the inside of quartz crucible 5 from discharge hole 14, can prevent like this when quartz holding bucket 15 rises or other reasons make sulfuric acid s...

Embodiment 3

[0042] Embodiment 3: The non-contact lifting structure 1 is composed of a rotating rod 101, a sling 102, a hollow sleeve 103, a turning handle 104 and a limit rod 105. The hollow sleeve 103 is fixedly connected to the top of the fixed frame 4, and the interior of the hollow sleeve 103 is horizontally A rotating rod 101 runs through it, and the rotating rod 101 is flexibly connected with the hollow sleeve 103. A hanging rope 102 is wound around the middle of the rotating rod 101, and the bottom end of the hanging rope 102 is fixedly connected with the top of the quartz holding bucket 15 through a fixing buckle. One side of the rotating rod 101 is fixedly connected with a rotating handle 104, and the limit rod 105 is movably hinged on one side of the fixed frame 4;

[0043] The hollow sleeve 103 is provided with two groups and distributed symmetrically about the vertical center line of the quartz holding bucket 15;

[0044] Specifically, such as figure 1 , Figure 4 and Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com