Automatic pit digging and soil making machine

A kind of planing and automatic technology, which is applied in the field of automatic planing and soil making machines, can solve the problems of failure to meet the requirements of breaking large stones, inapplicability, splashing, etc., to ensure the retention of stone chips, reduce labor costs, The effect of preventing stone chips from splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

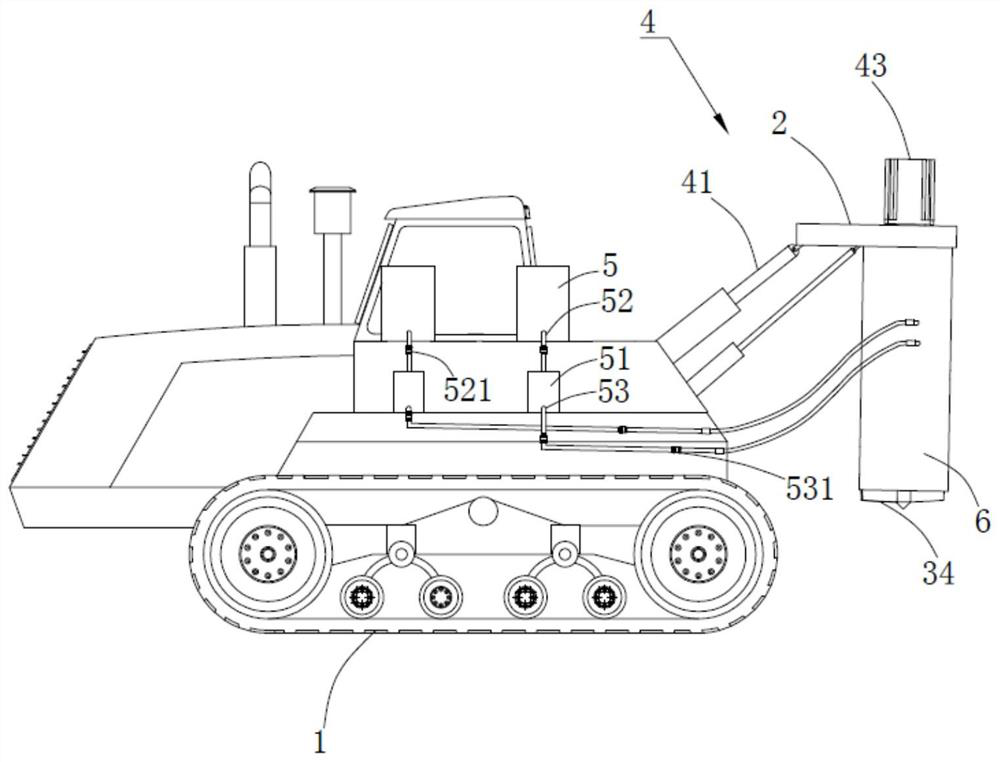

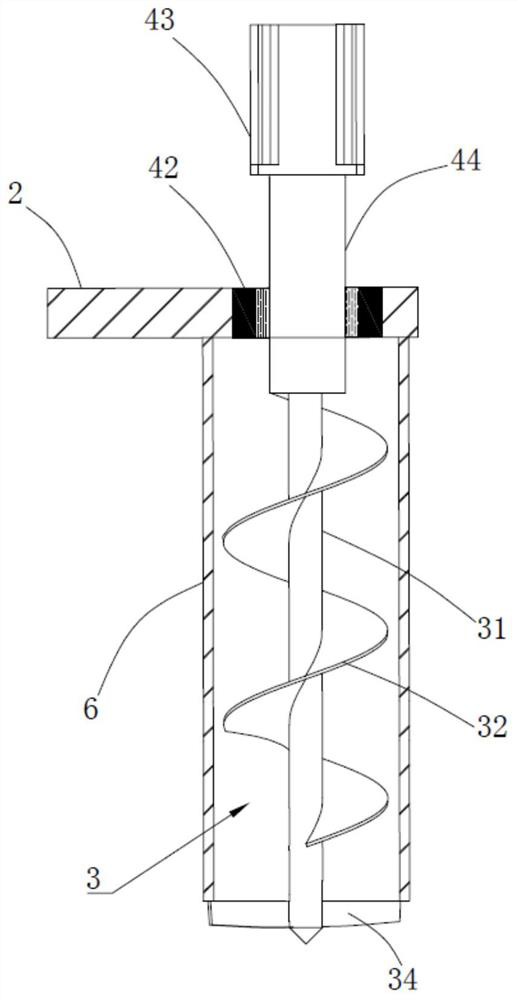

[0035] refer to figure 1 and figure 2 , is an automatic digging and soil making machine disclosed by the present invention, comprising a body 1, a knife holder 2, a pitting knife 3 arranged on the knife holder 2, and a driving mechanism 4 for driving the digging knife 3 to drill holes. The outer cover of the digging knife 3 is provided with a protective cover 6 that is fixedly connected to the knife rest 2; the body 1 is provided with two material boxes 5, and the material box 5 is connected to the inside of the protective cover 6 by a feed pipe 53, and the feed pipe 53 is provided with a supply The material valve 531 and the material box 5 are used to store additional materials such as root-growing powder, organic fertilizer, inorganic fertilizer, and water-retaining agent. Protective cover 6 is preferably a steel drum, because the setting of protective cover 6 can prevent the splash of stone chips produced in the digging process of pit knife 3, so that pit digging knife 3 ...

Embodiment 2

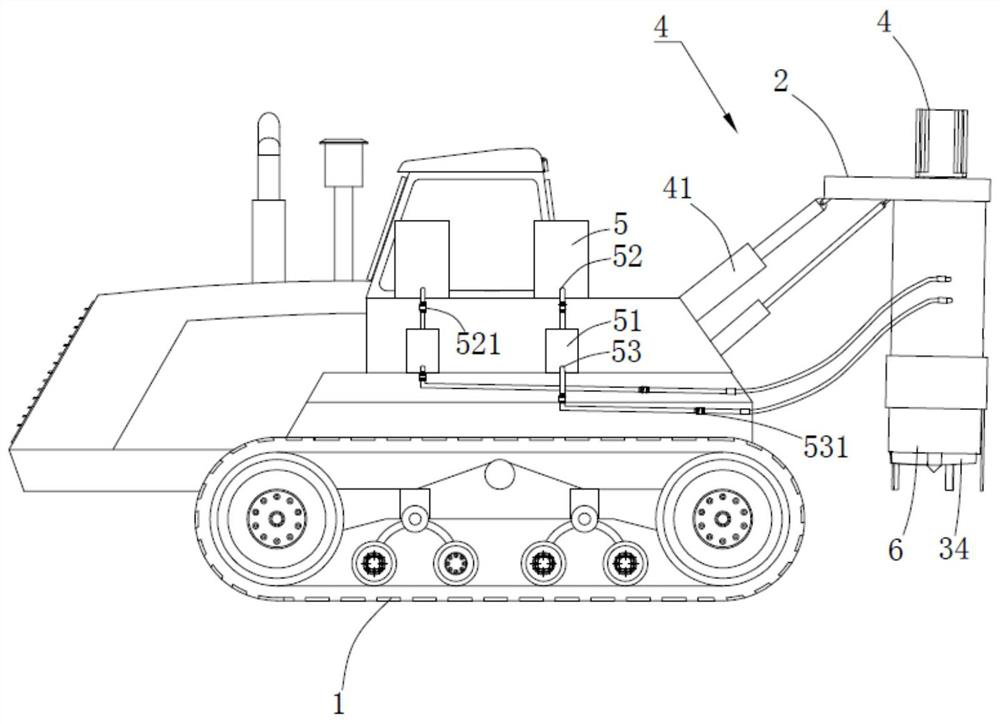

[0041] refer to image 3 and Figure 4 , is another automatic digging and soil making machine disclosed in the present invention, including a body 1, a knife holder 2, a pitting knife 3 arranged on the knife rest 2, and a driving mechanism 4 for driving the digging knife 3 to drill holes. The outer cover of the digging knife 3 is provided with a protective cover 6 that is fixedly connected to the knife rest 2; the body 1 is provided with two material boxes 5, and the material box 5 is connected to the inside of the protective cover 6 by a feed pipe 53, and the feed pipe 53 is provided with a supply The material valve 531 and the material box 5 are used to store additional materials such as root-growing powder, organic fertilizer, inorganic fertilizer, and water-retaining agent. Protective cover 6 is preferably a vertical steel drum, because the setting of protective cover 6 can prevent the splash of stone chips produced in the digging process of pit knife 3, so that pit diggi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com