Magnetic type template cover jig

A template cover, magnetic suction technology, applied in the direction of optics, optomechanical equipment, instruments, etc., can solve the problem of inconvenient operation, and achieve the effect of increasing difficulty and uniform support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

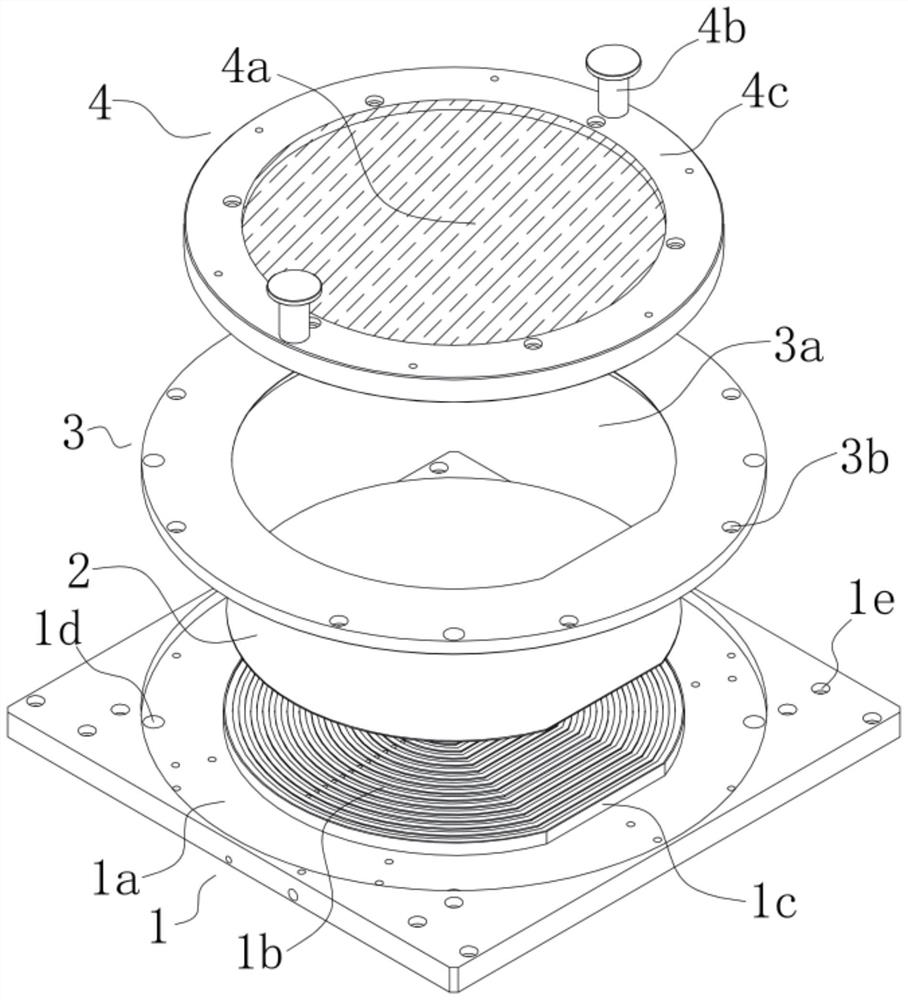

[0027] In order to achieve the purpose of the present invention, a magnetic suction formwork cover fixture includes: a base plate 1, the upper surface of which is equipped with a bearing surface 1b that matches the vertical projection of the formwork 2, and the outer contour of the bearing surface 1b is in the shape of a superior arc bow. There is a concave annular groove 1a around the surface 1b; the pressure ring 3 coincides with the vertical projection of the annular groove 1a, and the pressure ring 3 and the annular groove 1a are detachably assembled; the cover plate 4 includes the upper surface of the pressure ring 3. The cover ring 4c of adsorption force has a transparent plate 4a in the middle of the cover ring 4c, and an upwardly protruding handle 4b is also provided on the cover ring 4c; the pressure ring 3 and the cover ring 4c are made of ferromagn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com